Binding post apparatus without screw thread

A terminal and threadless technology, which is applied in the direction of contact parts, contact electrical connection, clamping/spring connection, etc., can solve the problem that the wiring range of the terminal cannot be expanded, the temperature rise index of the terminal cannot meet the standard requirements, and the small elastic sheet And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

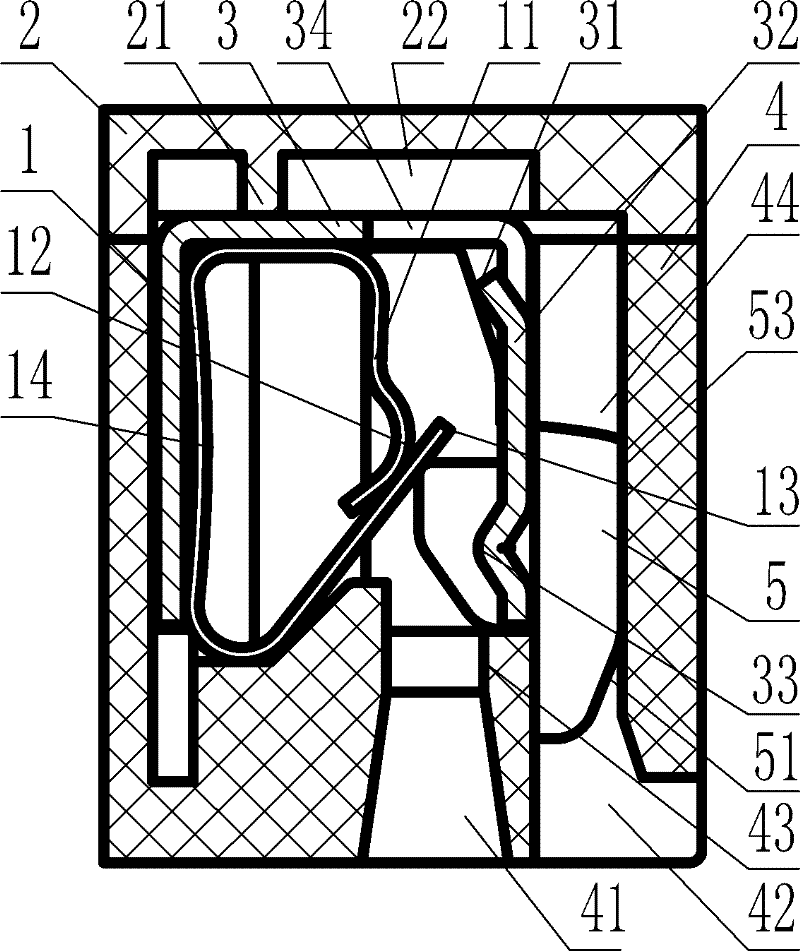

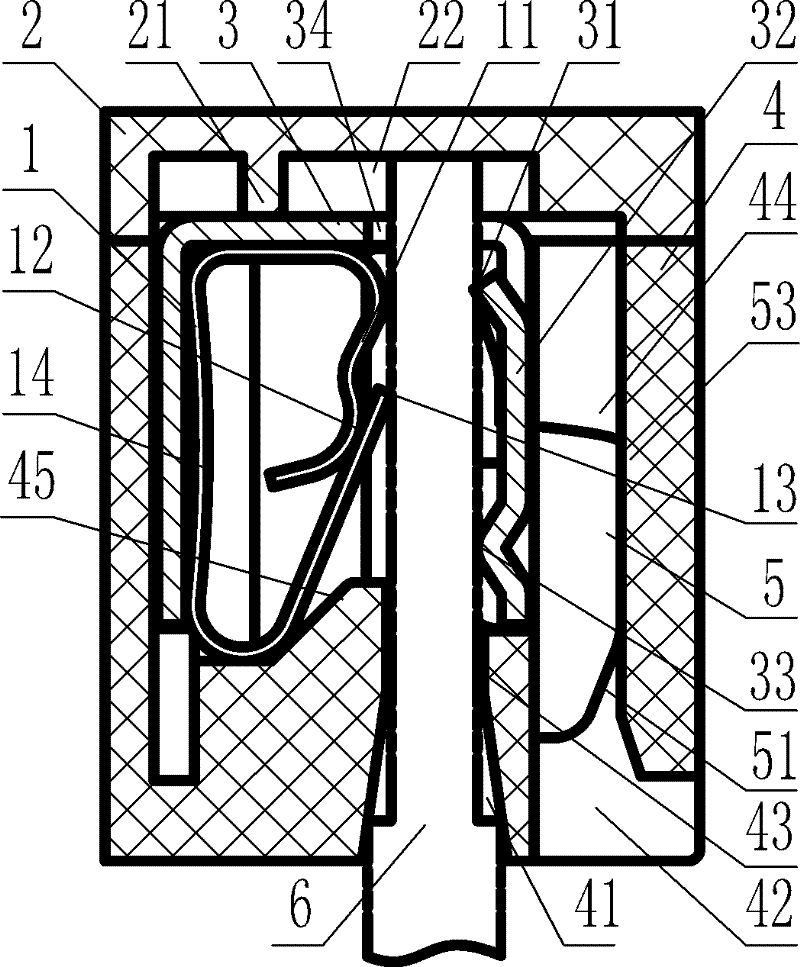

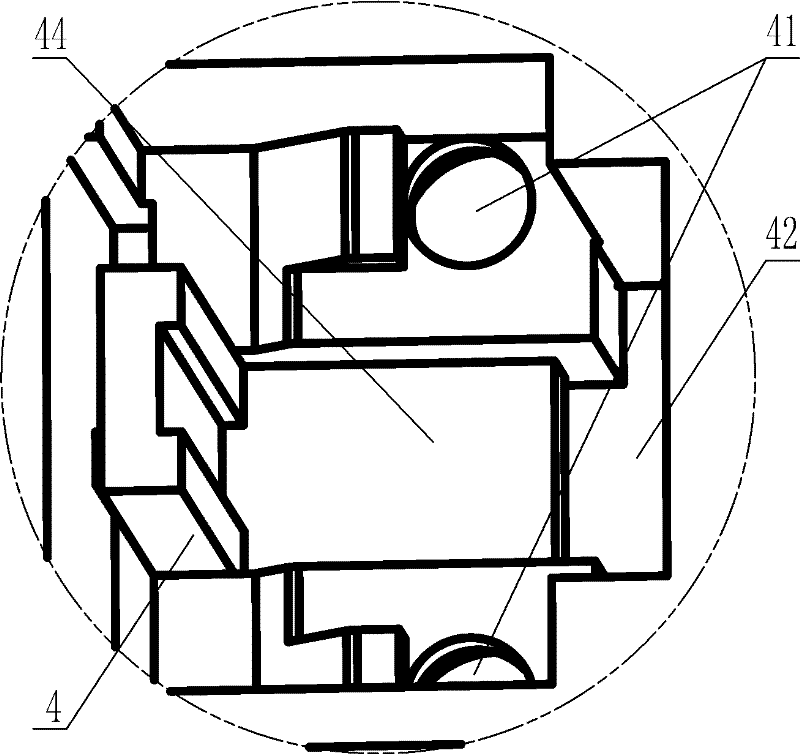

[0021] Combine below Figure 1 to Figure 9 The specific embodiment shown is a detailed description of the specific implementation of the screwless terminal device of the present invention. The screwless terminal device of the present invention is not limited to the following embodiments.

[0022] like Figures 1 to 3 As shown, the screwless terminal device of the present invention includes a main body 4, a conductive member 3 installed in the main body 4, an elastic member 1 installed in the conductive member 3, a retracting member 5 installed in the main body 4, and used for connecting The conductive element 3 , the elastic element 1 and the wire withdrawal element 5 are encapsulated in the pressing plate 2 inside the main body 4 . Inside the main body 4 is a cavity 44. The bottom surface of the cavity 44 is provided with a wire insertion hole 41 for conveniently inserting the wire 6 and a wire removal hole 42 for conveniently inserting an electrician's shell to push the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com