High-speed turbine section for turbine drilling tool

A technology of turbo drilling tools and turbines, which is applied in the field of petroleum machinery and oil exploration. It can solve the problems of large pressure loss, lowering the efficiency of turbo drilling tools, and drastic changes in the flow area, so as to reduce pressure loss and improve thrust force. Condition, effect of smooth change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

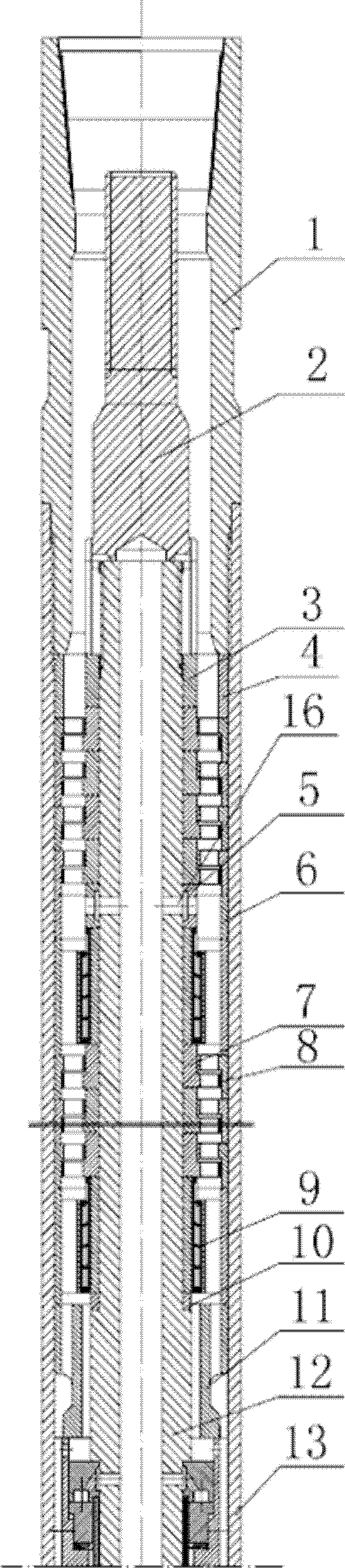

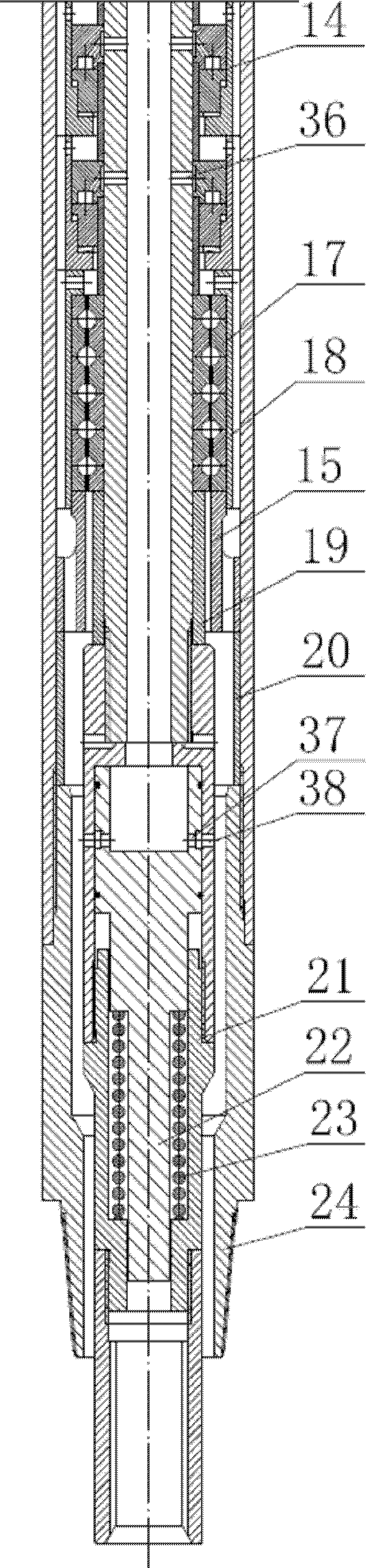

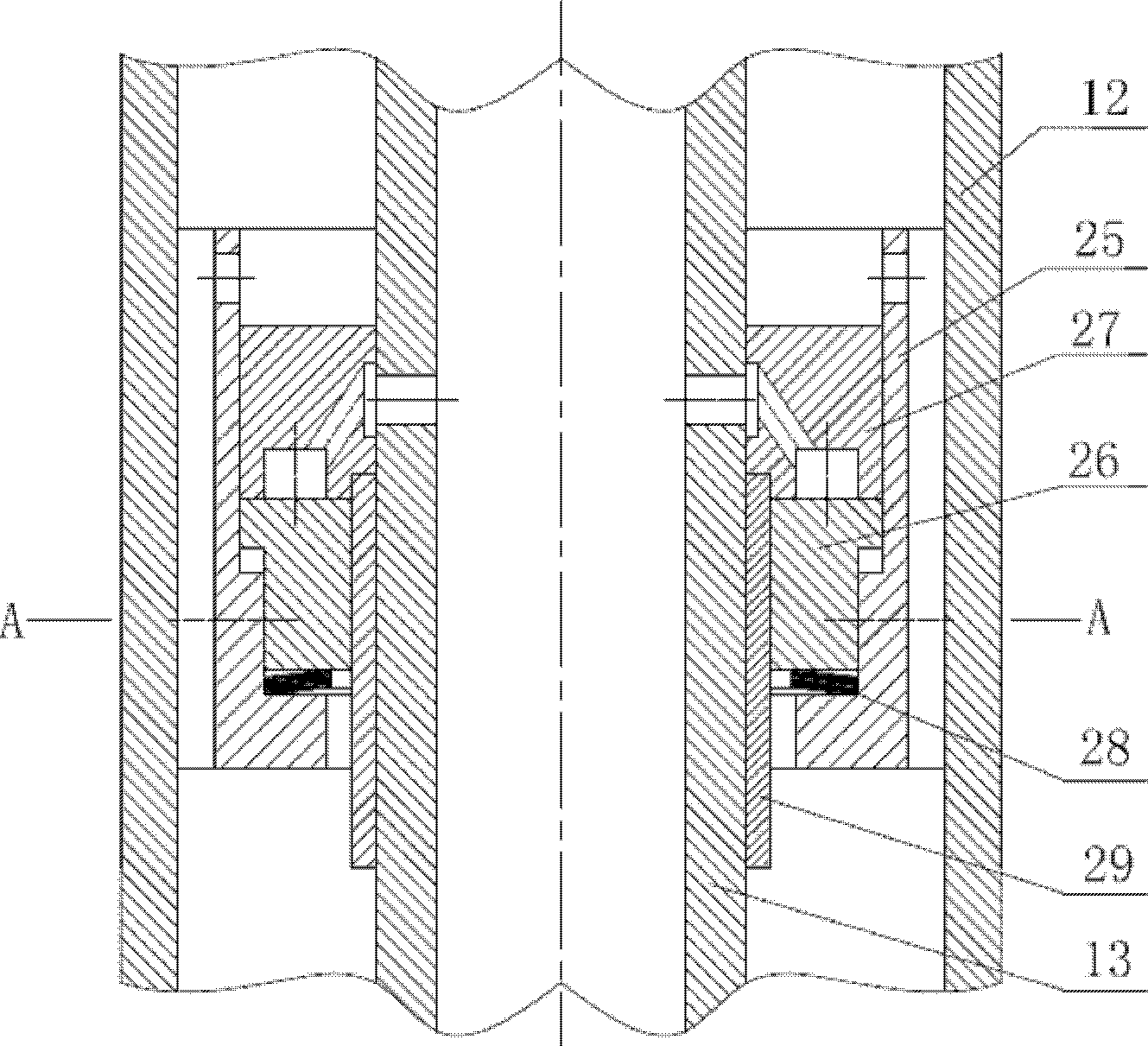

[0019] It includes a tubular casing 13, the two ends of the casing are respectively provided with an upper joint 1 with an internal taper thread and a lower joint 24 with an external taper thread, the casing is equipped with a turbine shaft 12, and the upper and lower ends of the turbine shaft are respectively threaded. The spline shaft 2 and the spline sleeve 21 are installed with a turbine assembly and a centering bearing 9 along the axial direction in the annular flow channel between the turbine shaft and the inner cavity of the housing. The turbine assembly is installed with 90 stages along the axial direction. The uppermost turbine assembly is equipped with 4 stages, and the uppermost 4-stage turbine assembly is used to filter mud impurities and prevent the upper radial through hole from being blocked. The centralizing bearings are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com