Diamond fine powder product material automatic collecting and water-circulating device and use method thereof

A technology of automatic collection of diamond micropowder, which is applied in the direction of settling tanks, etc., can solve the problems of difficult realization of functions, large amount of diamond micropowder, and many resources consumed, and achieve the effects of easy realization of functions, great social benefits, and low device consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

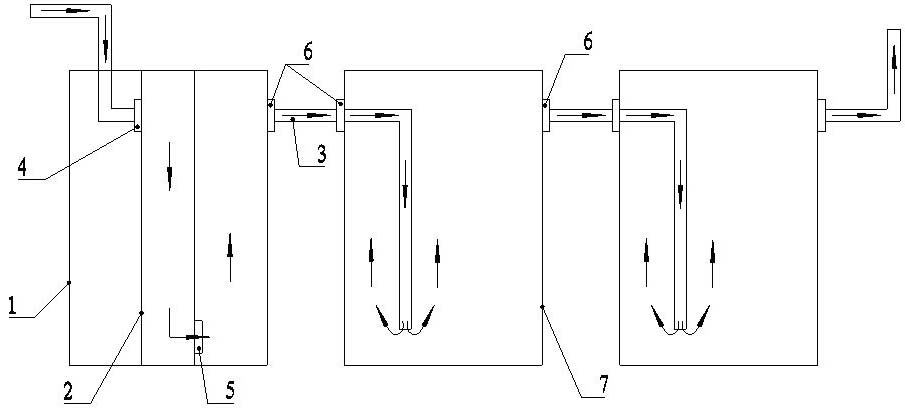

[0018] Such as figure 1 As shown, an automatic collection and water circulation device for diamond micropowder products includes a main settling tank 1 and an auxiliary settling tank 7 connected to the main settling tank 1 through a connecting pipe 3. The center of the main settling tank 1 is provided with a built-in tube 2. The built-in cylinder 2 is arranged in the axial direction and its lower end is in sealing contact with the bottom surface of the main settling cylinder 1, and its upper end is level with the top surface of the main settling cylinder 1. The upper part of the built-in cylinder 2 is provided with a material inlet 4, and the lower part is provided with a discharge Port 5, the upper part of the main settling cylinder 1 and the upper part of the auxiliary settling cylinder 7 are provided with a connecting pipe interface 6, one end of the connecting pipe 3 between the main settling cylinder 1 and the auxiliary settling cylinder 7 and the connecting pipe on the ma...

Embodiment 2

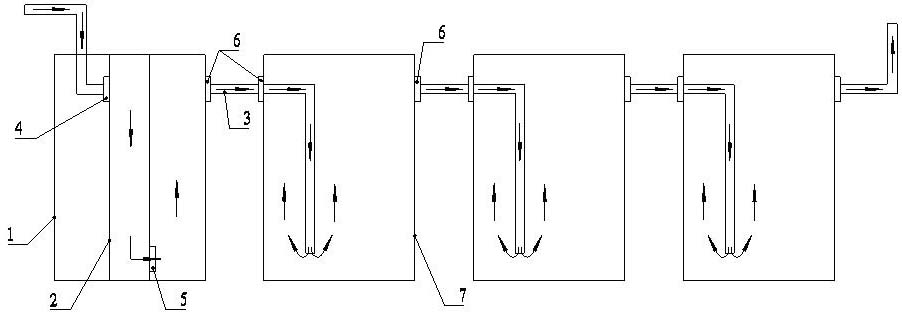

[0027] Such as figure 2 As shown, an automatic collection and water circulation device for diamond micropowder products includes a main settling tank 1 and an auxiliary settling tank 7 connected to the main settling tank 1 through a connecting pipe 3. The center of the main settling tank 1 is provided with a built-in tube 2. The built-in cylinder 2 is arranged in the axial direction and its lower end is in sealing contact with the bottom surface of the main settling cylinder 1, and its upper end is level with the top surface of the main settling cylinder 1. The upper part of the built-in cylinder 2 is provided with a material inlet 4, and the lower part is provided with a discharge Port 5, the upper part of the main settling cylinder 1 and the upper part of the auxiliary settling cylinder 7 are provided with a connecting pipe interface 6, one end of the connecting pipe 3 between the main settling cylinder 1 and the auxiliary settling cylinder 7 and the connecting pipe on the m...

Embodiment 3

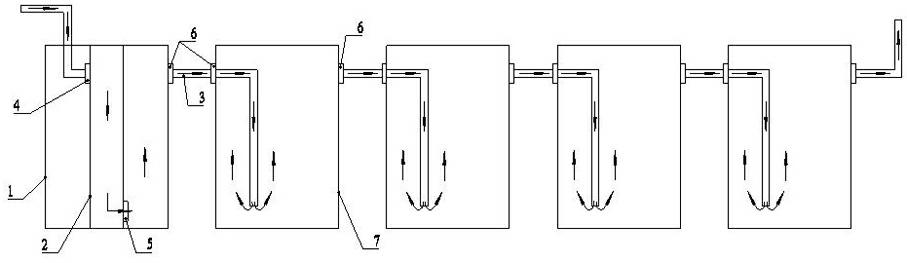

[0036] Such as image 3 As shown, an automatic collection and water circulation device for diamond micropowder products includes a main settling tank 1 and an auxiliary settling tank 7 connected to the main settling tank 1 through a connecting pipe 3. The center of the main settling tank 1 is provided with a built-in tube 2. The built-in cylinder 2 is arranged in the axial direction and its lower end is in sealing contact with the bottom surface of the main settling cylinder 1, and its upper end is level with the top surface of the main settling cylinder 1. The upper part of the built-in cylinder 2 is provided with a material inlet 4, and the lower part is provided with a discharge Port 5, the upper part of the main settling cylinder 1 and the upper part of the auxiliary settling cylinder 7 are provided with a connecting pipe interface 6, one end of the connecting pipe 3 between the main settling cylinder 1 and the auxiliary settling cylinder 7 and the connecting pipe on the ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap