Electro-adsorption desalting regeneration system and regeneration process

A regeneration system and electro-adsorption technology, applied in the field of water treatment, can solve the problem of low adsorption efficiency, and achieve the effect of improving the salt removal rate, compact operation process of the module, and tapping the potential of the module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

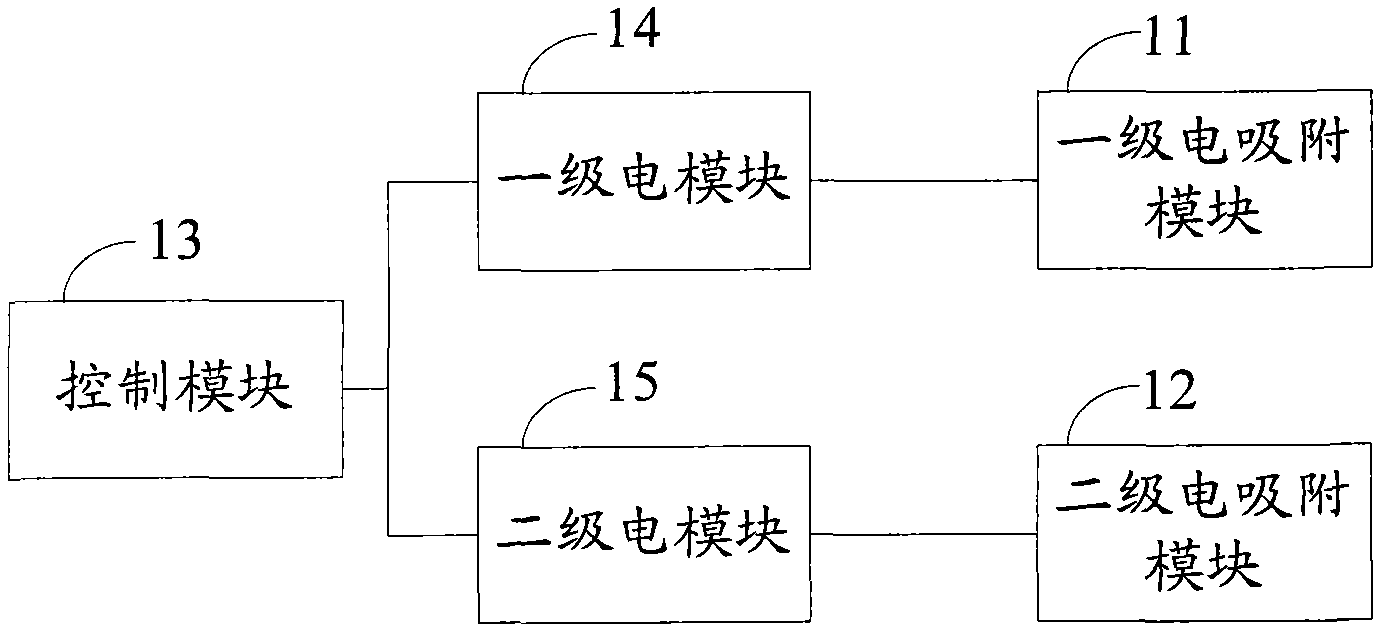

[0019] Embodiment 1. This embodiment provides an electro-adsorption desalination regeneration system, see figure 1 As shown, it includes: a primary electric adsorption module 11, a secondary electric adsorption module 12, a control module 13, a primary electric module 14 and a secondary electric module 15; the primary electric module 14 is electrically connected with the primary electric adsorption module 11, The secondary electric module 15 is electrically connected to the secondary electric adsorption module 12 , and the control module 13 is connected to the primary electric module 14 and the secondary electric module 15 .

[0020] The first-level electrosorption module 11 and the second-level electrosorption module 12 are used to enter the raw water from the bottom of the first-level electrosorption module 11 and output from the top of the first-level electrosorption module 11 during the working process. The raw water of the adsorption module 12 enters from the bottom of th...

Embodiment 2

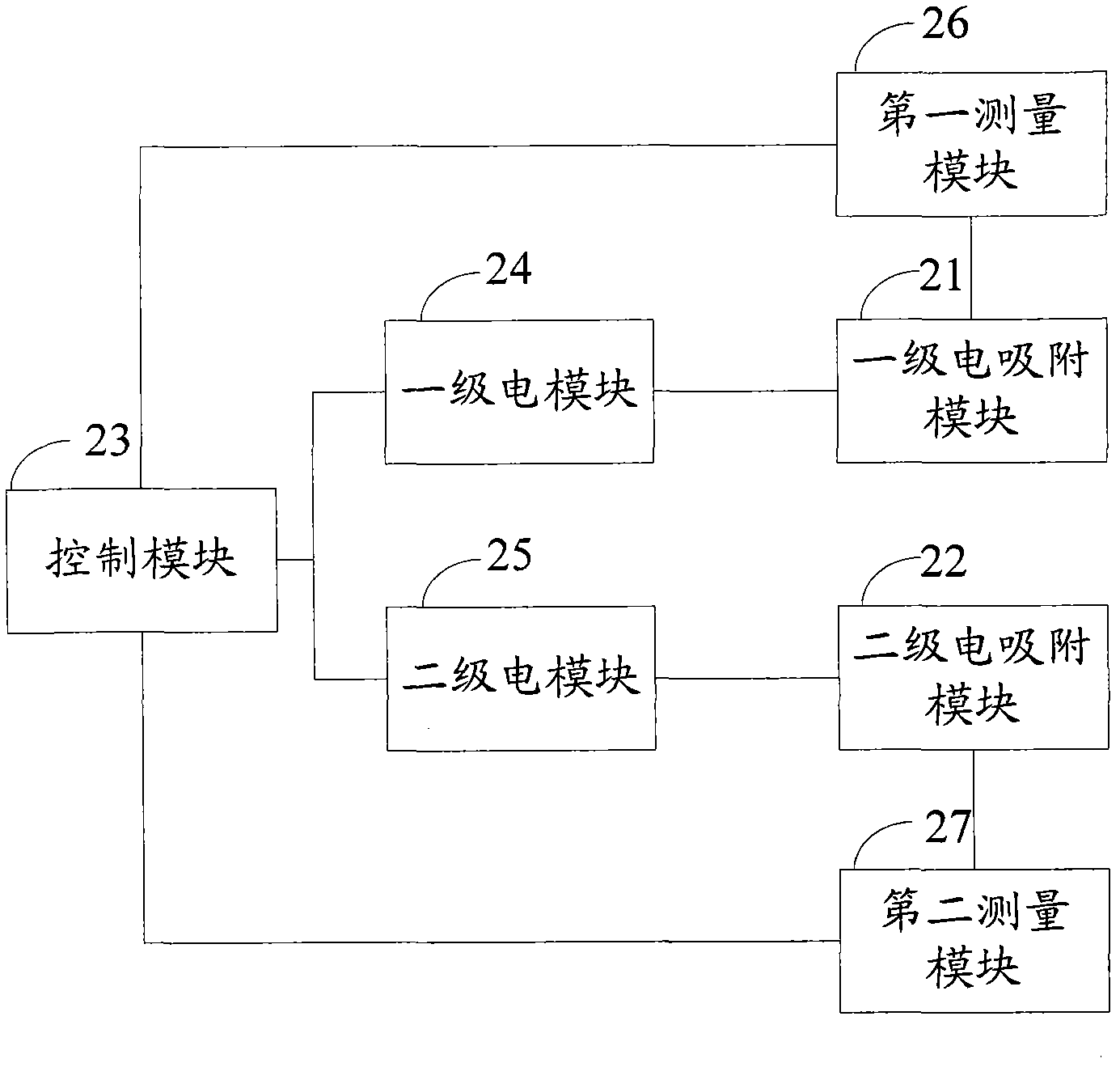

[0024] Embodiment 2. This embodiment provides an electro-adsorption desalination regeneration system, see figure 2 As shown, it includes: a primary electric adsorption module 21, a secondary electric adsorption module 22, a control module 23, a primary electric module 24, a secondary electric module 25, a first measurement module 26 and a second measurement module 27; The module 24 is electrically connected to the first-level electric adsorption module 21, the second-level electric module 25 is electrically connected to the second-level electric adsorption module 22, the control module 23 is connected to the first-level electric module 24 and the second-level electric module 25, and the first measurement module 26 is connected to the second-level electric module 25. The primary electrosorption module 21 is connected to the control module 23 , and the second measurement module 27 is connected to the secondary electrosorption module 22 and the control module 23 .

[0025] Among...

Embodiment 3

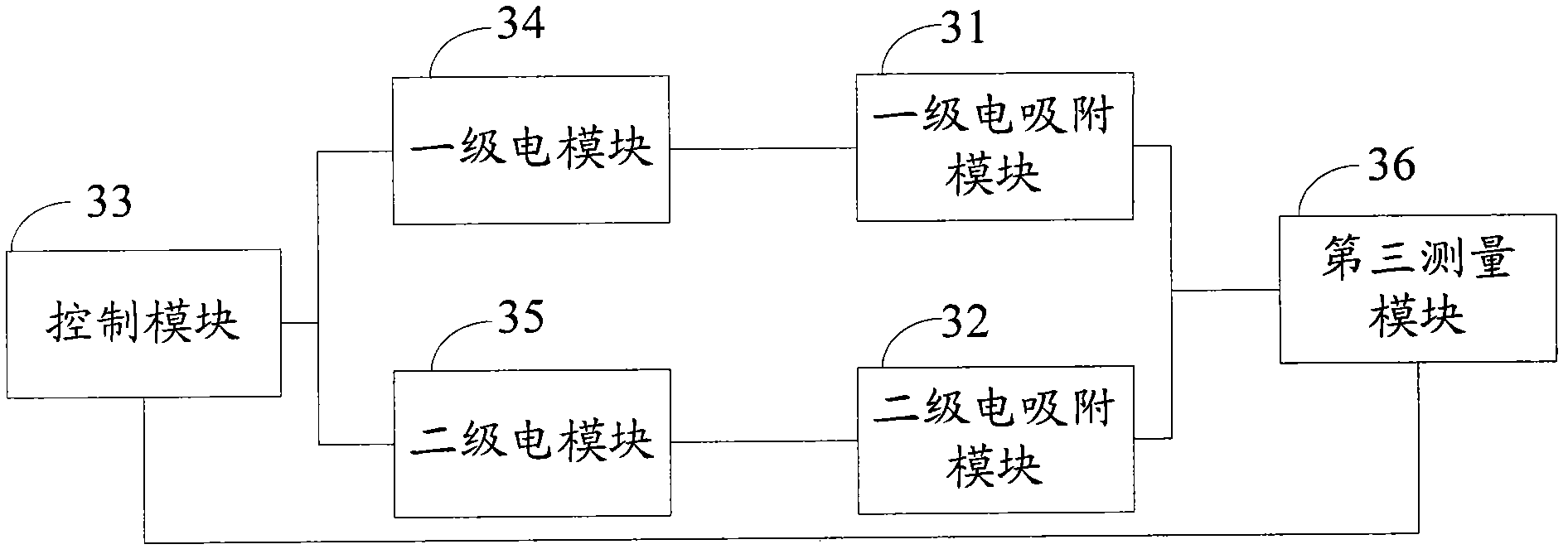

[0027] Embodiment 3. This embodiment provides an electro-adsorption desalination regeneration system, see image 3As shown, it includes: a primary electric adsorption module 31, a secondary electric adsorption module 32, a control module 33, a primary electric module 34, a secondary electric module 35 and a third measurement module 36; the primary electric module 34 and the primary electric The adsorption module 31 is electrically connected, the secondary electrical module 35 is electrically connected to the secondary electrical adsorption module 32, the control module 33 is connected to the primary electrical module 34 and the secondary electrical module 35, and the third measurement module 36 is connected to the primary electrical adsorption module 31 , the secondary electrosorption module 32 and the control module 33 are connected.

[0028] Among them, the functions and cooperative relations of the first-level electrosorption module 31, the second-level electrosorption modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com