Loop trolley fixing device

A looper trolley and fixing device technology, applied in bending workpieces, metal processing equipment, metal rolling, etc., can solve problems such as affecting the quality of the steel strip, scratching the surface of the steel strip, and the trolleys cannot be equidistantly arranged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

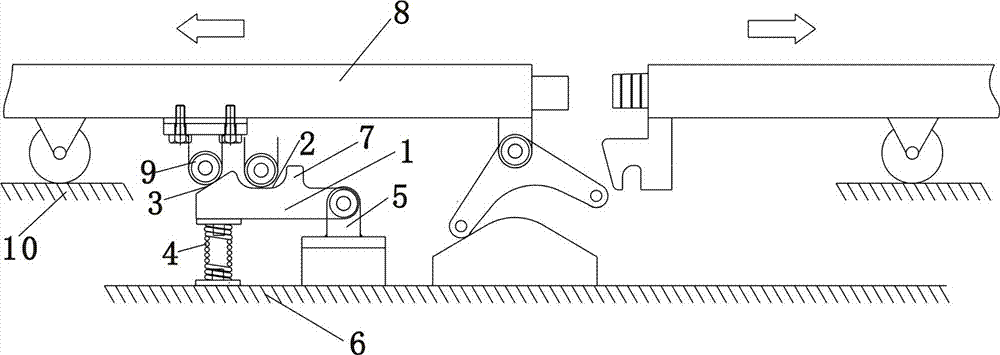

[0014] Such as figure 1 As shown, the looper trolley fixing device includes a swing arm 1, a groove 2 is provided on the swing arm 1, an inclined surface 3 is provided at one end of the swing arm 1, and an elastic member 4 is fixedly connected to the bottom of one end of the swing arm 1. , the other end of the swing arm 1 is hinged to the fixed pile 5, and the elastic member 4 and the fixed pile 5 are fixedly connected to the ground 6.

[0015] Said swing arm 1 is provided with a protrusion 7, and when the roller 9 enters the groove 2 of the swing arm 1, it also acts as a limit stop to prevent the roller 9 of the looper trolley 8 from rushing out of the swing arm 1.

[0016] The elastic member 4 is a spring. The expansion and contraction of the spring ensures that the roller 9 is in contact with the inclined surface 3 and the groove 2 on the swing arm 1 .

[0017] The fixed pile 5 includes a pier fixed on the ground 6, on which a hinged seat is fixed. The hinged seat is mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com