Forming mould for pressing reinforcing ribs on high-strength sheet steel

A technology for forming molds and thin steel plates, which is applied in the field of forming molds and sheet metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

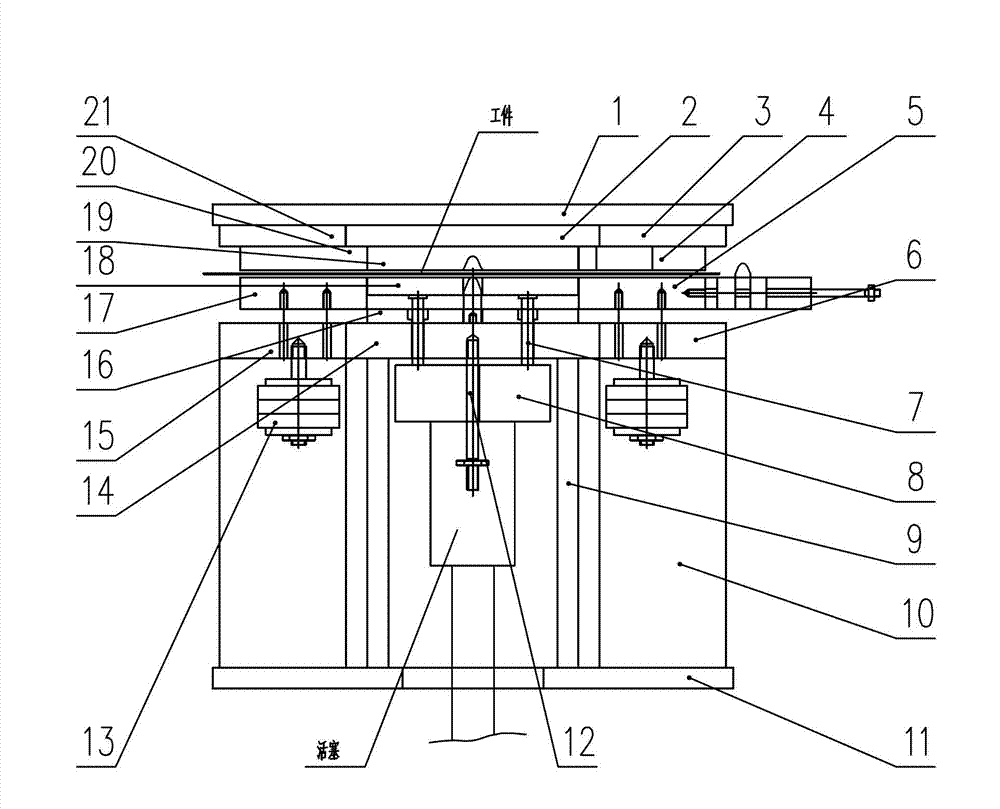

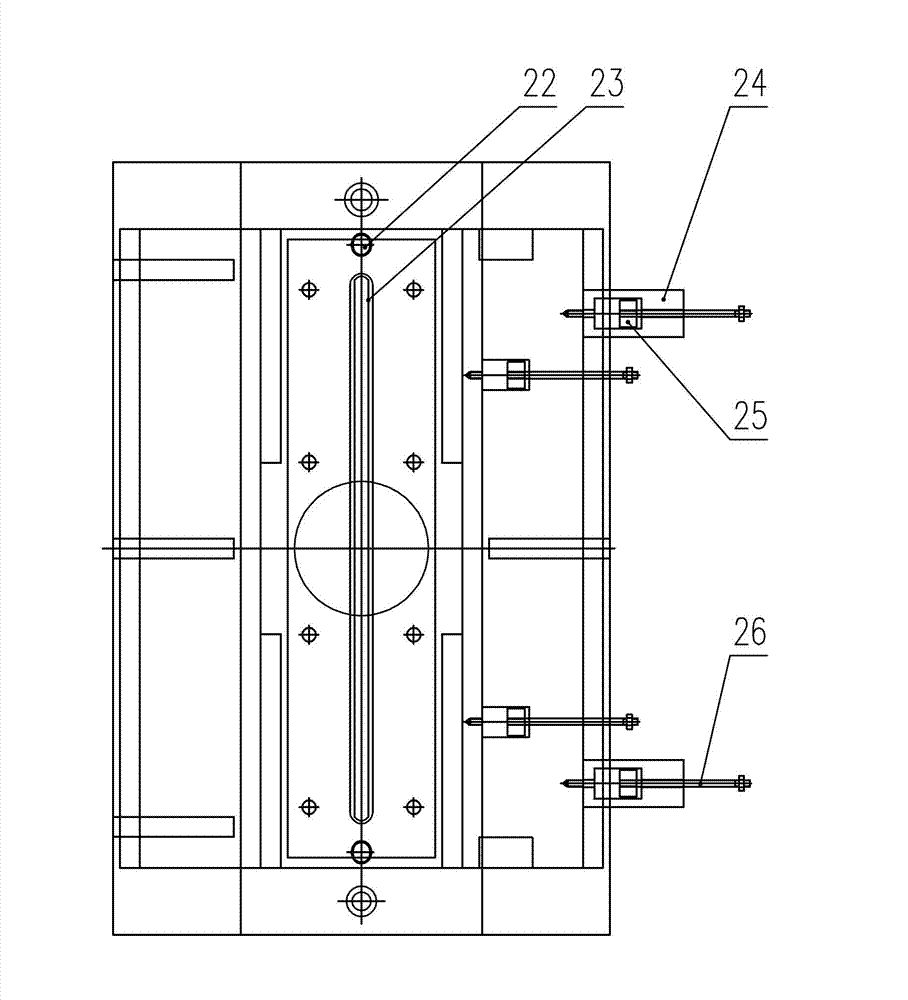

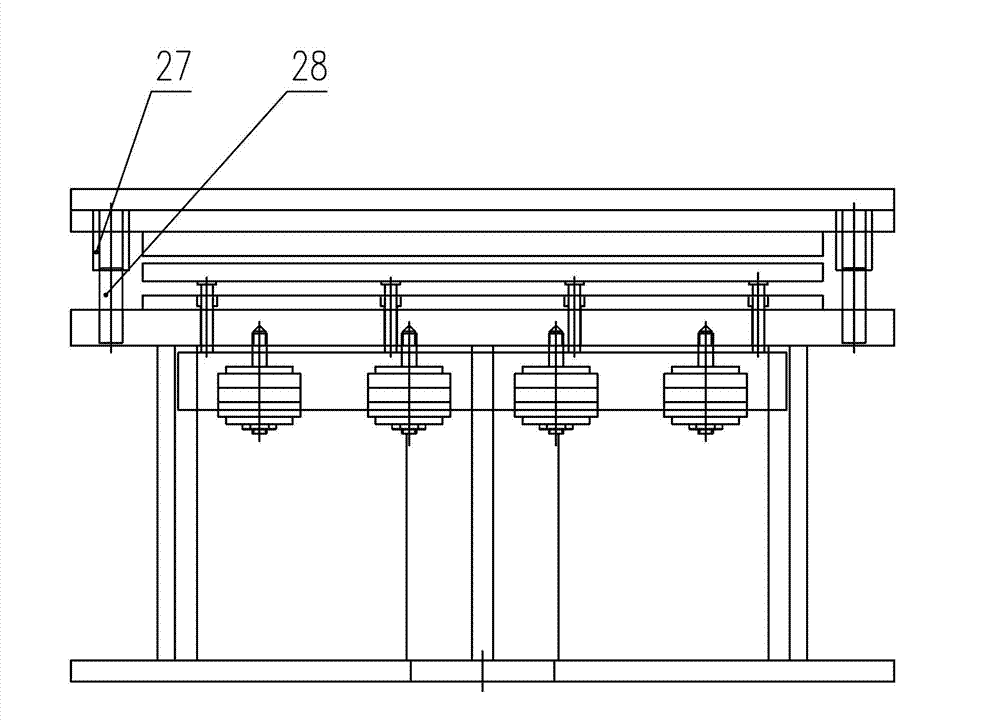

[0018] Such as figure 1 , figure 2 Shown, the present invention is made up of upper mold and lower mold. Among them, the upper mold is composed of the upper mold base plate 1, the upper mold plate 2, the outer extension backing plate of the right upper mold 3, the first upper mold pressing plate 4, the forming die 19, the second upper mold pressing plate 20, and the left upper mold outer extension plate The backing plate 21 is combined by bolt connection; the lower mold is composed of the first lower mold pressing plate lower 5, the outer extension backing plate 6 of the right lower mold, the ejector rod 7, the top plate 8, the feet 9, the outer extension feet 10, and the bottom plate of the lower mold 11 , top plate guide rod 12, elastic rubber 13, lower template 14, outer extension backing plate 15 of the left lower mold, punch fixing plate 16, s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap