Curved surface die on special-shaped curved surface quick formation machine

A special-shaped curved surface and forming machine technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, low efficiency, waste power, etc., and achieve the effect of smooth surface, small damage, and easy and free forming of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

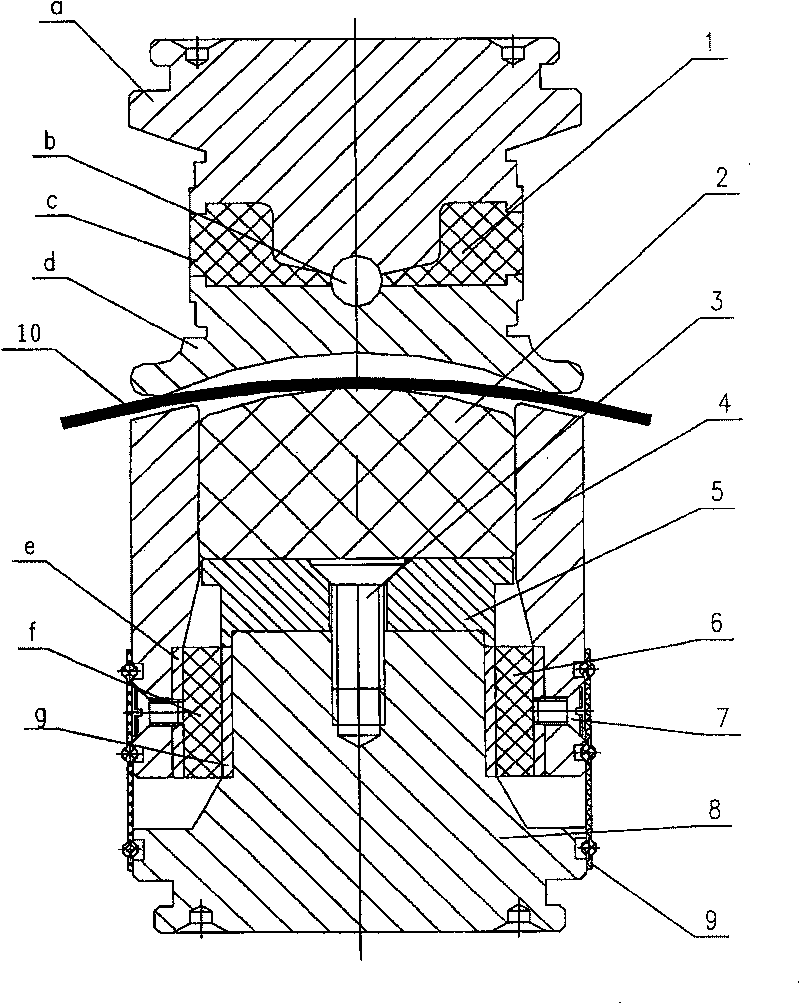

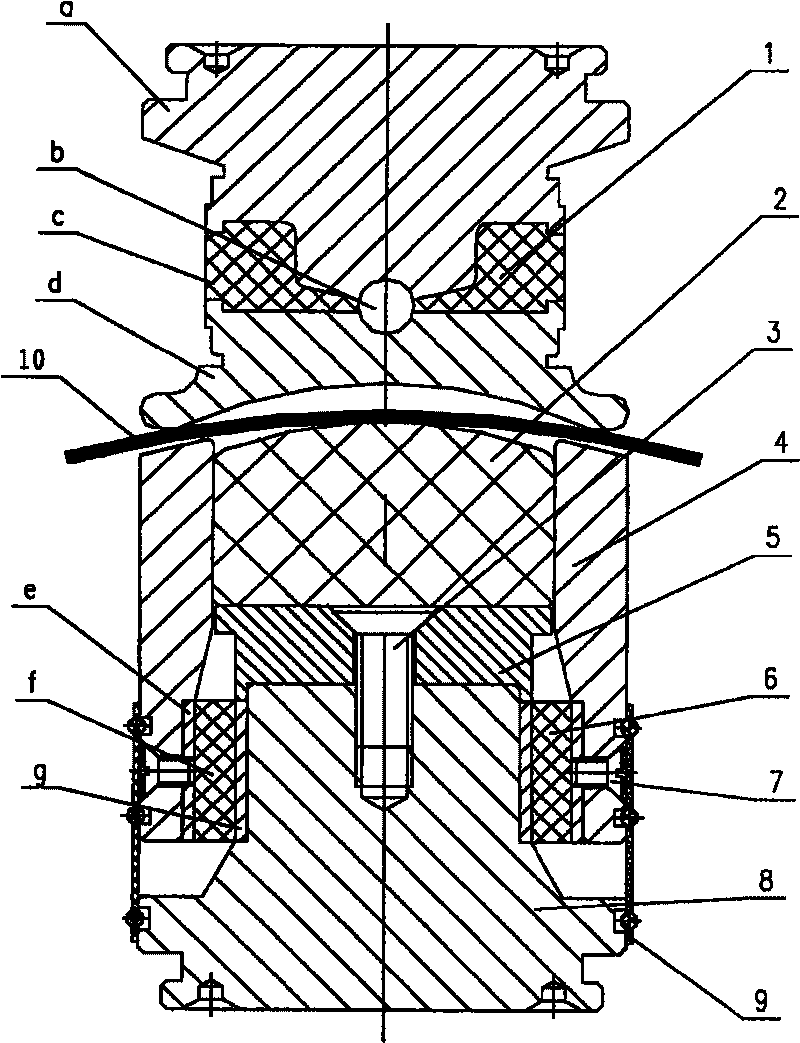

[0011] Such as figure 1 Shown, mold of the present invention is made up of upper mold 1 and lower mold. Among them, the upper mold 1 is integrally cast by the upper mold seat a, the steel ball b, and the upper mold body d through special rubber c; the lower mold is made of hardwood 2, large cross-recessed countersunk screws 3, lower mold pad 4, and gland 5. The elastic block 6, the small cross recessed countersunk screw 7, the lower mold base 8, and the sheath 9 are composed. The elastic block 6 is formed by casting the outer sleeve e and the inner sleeve g through special rubber f.

[0012] The upper mold 1 and the lower mold base 8 of the present invention are respectively connected with the special-shaped curved surface rapid prototyping machine. The upper die is connected to the punch of the special-shaped curved surface rapid prototyping machin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap