Totally chlorine-free bleaching method of bamboo pulp for producing Daqian writing and painting paper

A completely chlorine-free, painting and calligraphy paper technology, applied in pulp bleaching, cellulose pulp post-processing, papermaking, etc., can solve problems such as pollution, achieve the effect of reducing pollution load, good ink rhythm, and facilitating subsequent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

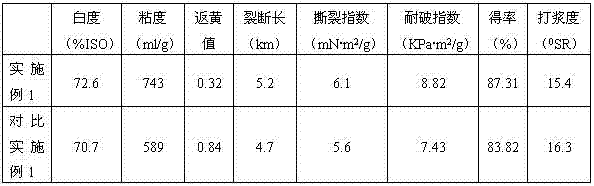

Embodiment 1

[0031] Raw materials: unbleached bamboo pulp made by kraft method, whiteness of unbleached bamboo pulp is 31.7%ISO, kappa number is 20.8, viscosity is 1056ml / g, beating degree is 11.70 Sr.

[0032] The bleaching process is as follows:

[0033] (1) Oxygen delignification bleaching: adjust the concentration of the unbleached bamboo pulp to 8%, introduce oxygen into the pulp, and the pressure of oxygen is 0.3MPa, then add sodium hydroxide, magnesium sulfate, and bleaching aids, React at 120°C for 30 minutes, wash the slurry after the reaction, and store the washed slurry for use in the next bleaching process. The weights of sodium hydroxide, magnesium sulfate and bleaching aids are respectively 5.0%, 0.8% and 0.1% of the absolute dry weight of the slurry. Among them, the bleaching aid is composed of the following components by weight percentage: 15% sodium dodecylbenzene sulfonate, 20% sodium lignosulfonate, 22% anthraquinone derivatives, 29% sodium sulfite, 14% sodium tripolyph...

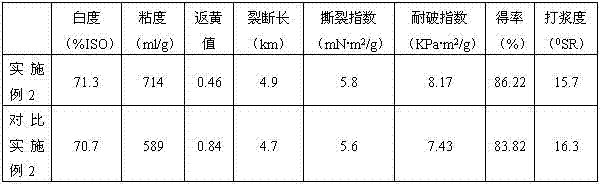

Embodiment 2

[0044] Raw materials: exactly the same as Example 1.

[0045] The bleaching process is as follows:

[0046] (1) Oxygen delignification and bleaching: adjust the concentration of unbleached bamboo pulp to 10%, introduce oxygen into the pulp, the pressure of oxygen is 0.6MPa, then add sodium hydroxide and magnesium sulfate, at 100°C, React for 60 minutes, wash the slurry after the reaction, and store the washed slurry for use in the next bleaching process. Wherein, the weights of sodium hydroxide and magnesium sulfate are respectively 4.0% and 1.0% of the absolute dry weight of the slurry.

[0047] (2) Peroxyacid bleaching: Take the slurry prepared in step (1), add water to adjust the concentration to 5%, then add peroxysulfuric acid to it, adjust the pH value of the slurry to 4.5, then add DTPA to it, at 90°C Next, react for 120min. After the reaction, the slurry is washed, and the washed slurry is stored for the next bleaching process. Wherein, the weights of peroxysulfuric...

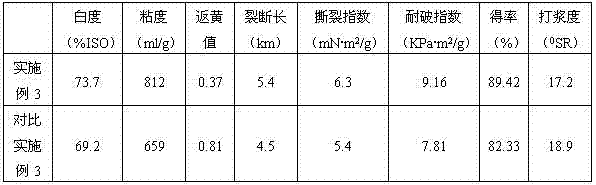

Embodiment 3

[0057] Raw material: Unbleached bamboo pulp prepared by Sichuan Yongfeng Pulp & Paper Co., Ltd. by kraft method. The whiteness of the unbleached pulp is 32.3% ISO, the kappa number is 19.4, the viscosity is 1097ml / g, and the beating degree is 13.1 0 Sr.

[0058] The bleaching process is as follows:

[0059] (1) Oxygen delignification bleaching: adjust the concentration of unbleached bamboo pulp to 10%, pass oxygen into the pulp, and the pressure of oxygen is 0.6MPa, then add sodium hydroxide, magnesium sulfate, and bleaching aids, at 120 ℃, react for 30min, wash the slurry after the reaction, and store the washed slurry for use in the next bleaching process. The weights of sodium hydroxide, magnesium sulfate and bleaching aids are respectively 3.0%, 0.5%, and 0.3% of the absolute dry weight of the slurry. Among them, the bleaching aid is composed of the following components by weight percentage: 5% sodium dodecylbenzene sulfonate, 17% sodium lignosulfonate, 15% anthraquinone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com