carrier tape holder

A carrier and paper tape technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of personnel operating environment, poor products, affecting the dust content of the workshop hygiene workshop, etc., to achieve convenient use and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

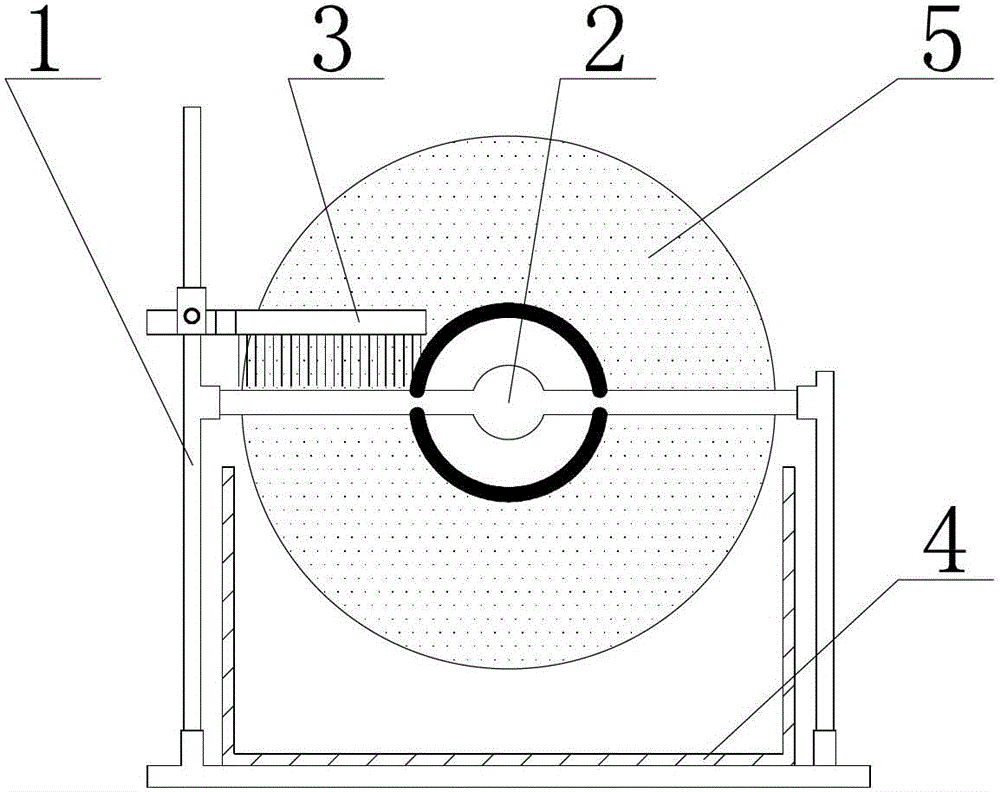

[0012] The present invention will be further explained below in conjunction with the drawings.

[0013] Such as figure 2 Shown is a carrier paper tape rack, including a bracket 1, a mounting shaft of the carrier paper tape roll 2, two brushes 3, and a debris storage box 4. The mounting shaft 2 and the brush 3 are both fixed on the bracket 1 When the carrier paper tape roll is installed on the mounting shaft 2, the brush heads of the two brushes 3 respectively brush the two side ends of the carrier paper tape roll, and the debris storage box 4 is located below the carrier paper tape roll .

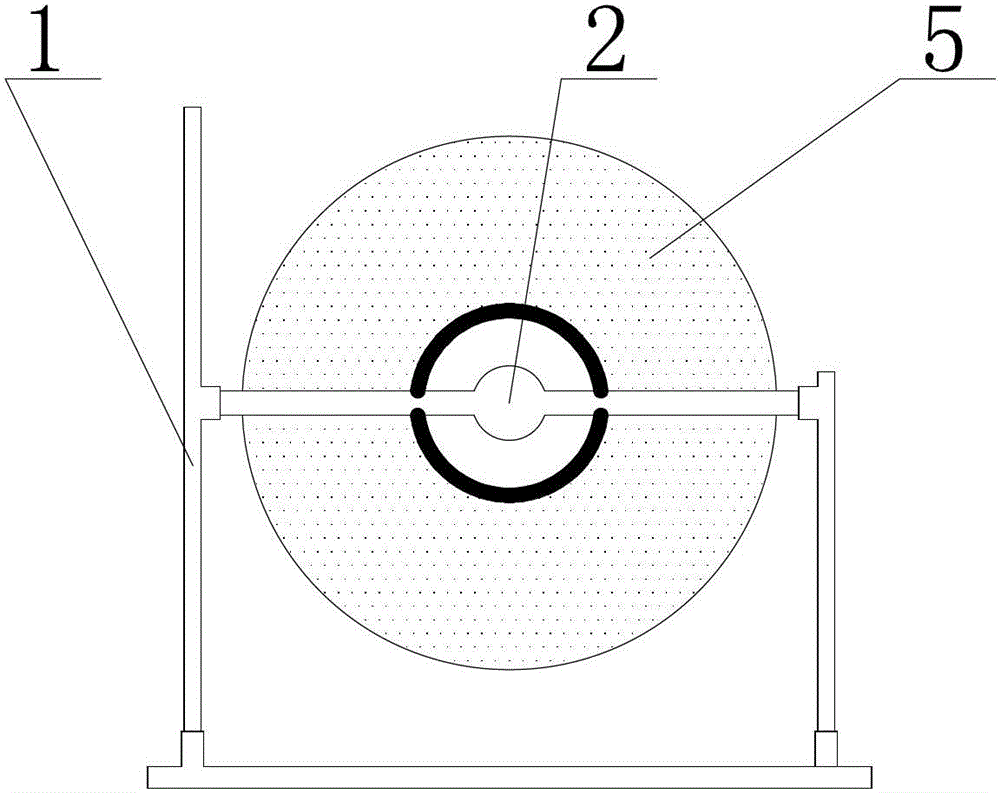

[0014] Compared with this case figure 1 In the prior art, a brush 3 and a debris storage box 4 are added.

[0015] The above are only the preferred embodiments of the present invention. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, several improvements and modifications can be made, and these improvements and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com