Construction control method capable of realizing unstressed line shapes of pushing construction beam bodies at high accuracy

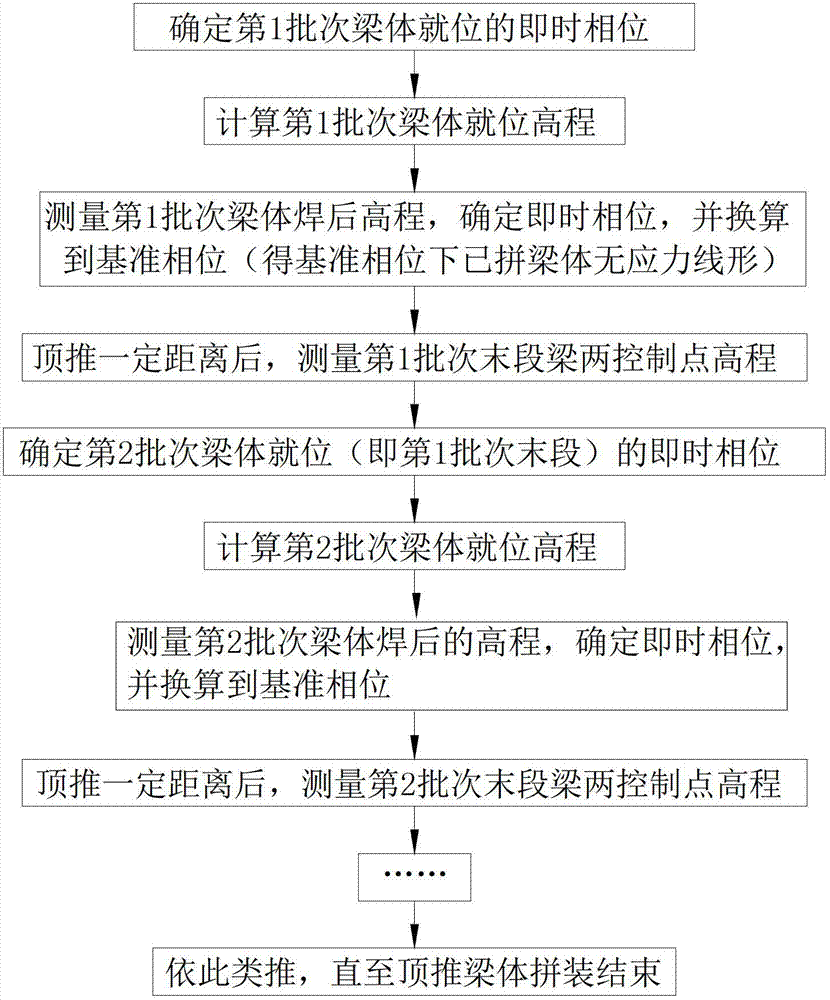

A control method and a technology of jacking construction, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to understand steps and methods, inconvenient to apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described in detail in conjunction with specific implementation examples below.

[0116] 1. Project overview

[0117] The superstructure of the approach bridge in the west of the Xiangjiang River Bridge is a steel-concrete composite structure continuous girder bridge with a single-box single-chamber truss with a large cantilever structure at the same height. The span of the center line of the bridge is (from west to east) 55m+85m+78m+21.785m Figure 5 ), the cross-section of the main beam of the composite structure is as follows Image 6 shown.

[0118] The approach bridge adopts the construction method of pushing the steel channel girder first and then laying the prefabricated bridge deck: after the steel channel girder is pushed into place, the concrete joint section at the bottom edge of the steel girder on the pier top is poured first, and then the bridge deck is laid in the specified order—now Wet the joints - stretch the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com