Testing apparatus for quantitatively characterizing wax crystal aggregation of wax-bearing crude oil and quantitative characterizing method of testing apparatus

A quantitative characterization and test device technology, applied in measurement devices, material inspection products, instruments, etc., can solve problems such as unreliable quantitative parameters, unsynchronized wax crystal images, loss of image grayscale information, etc., to achieve convenient mathematical expression, The effect of ensuring scientificity and reliability and reducing the loss of image information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070]Below in conjunction with accompanying drawing, the present invention will be further described:

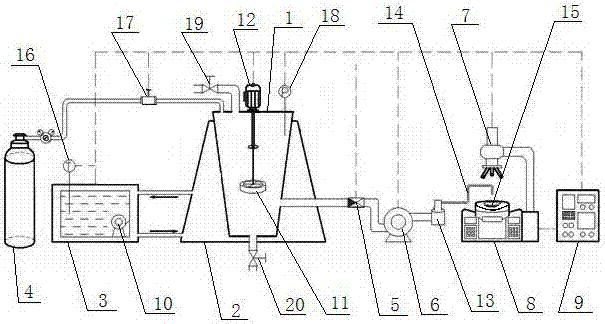

[0071] Such as figure 1 As shown, this experimental device for quantitatively characterizing the wax crystal accumulation of waxy crude oil includes a water-resistant copper shear tank 1 with a circulating water jacket 2 on the outer wall. In order to ensure the reproduction and acquisition of the effective shear effect in a certain shear mode, the The taper of 1:2 is adopted; the program-controlled bath 3 embedded with the internal circulation pump 10 is docked with the circulating water jacket 2 to realize the continuous adjustment and control of the uniform thermal conditions in the water-proof copper shearing tank 1, and the monitoring and utilization of the corresponding temperature The temperature sensor 16 in the program-controlled bath 3, and the inert gas pressure source 4 is connected to the water-proof copper shear tank 1 through the pressure control valve 17 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com