Traction method for enabling parallel built ships of 300,000 dry docks to undock

A dry-dock, parallel technique used in shipbuilding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

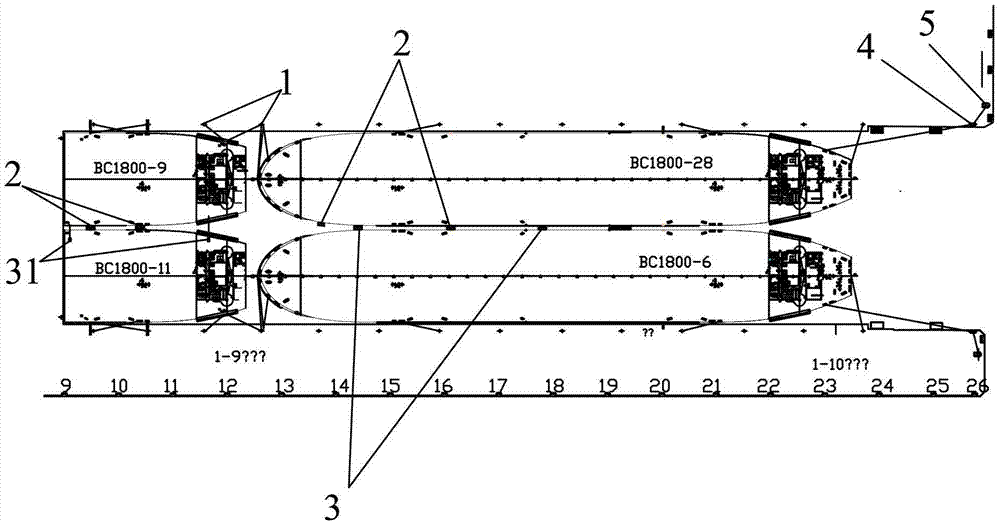

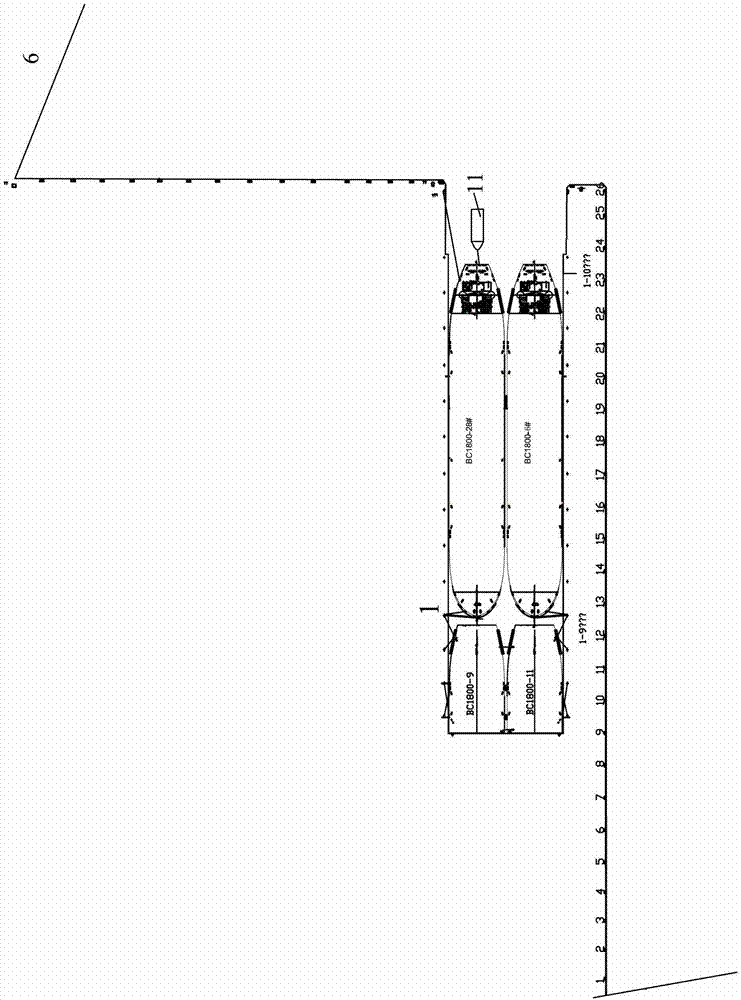

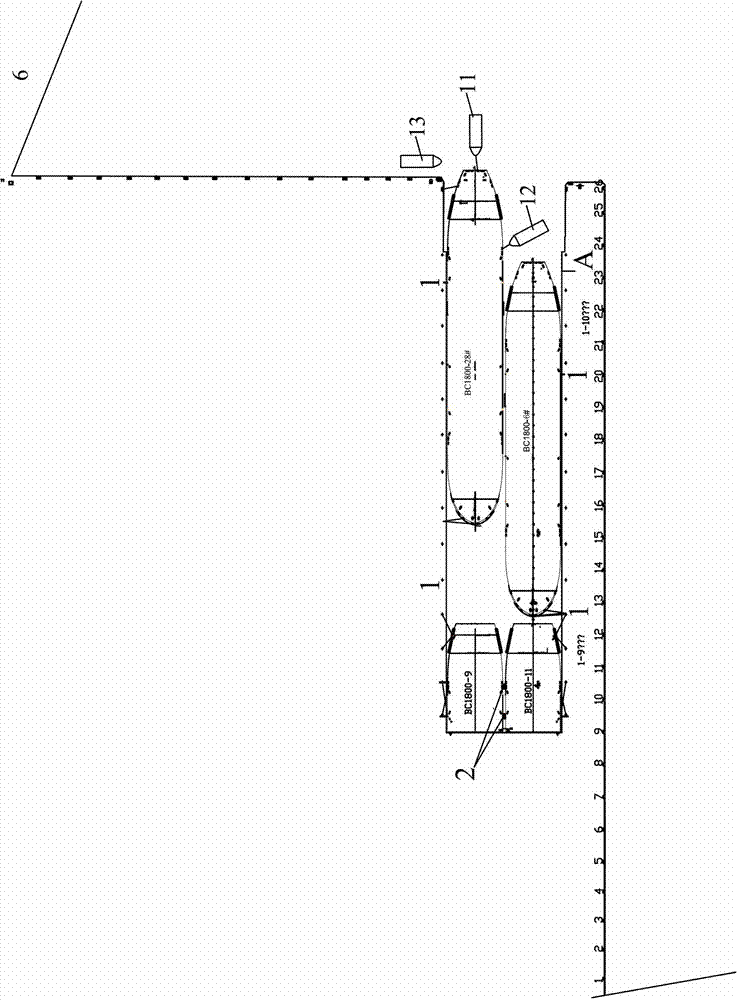

Method used

Image

Examples

Embodiment Construction

[0030] Traction prerequisites:

[0031] 1. The distance between the whole ship and the half section of parallel ships in the dock is small, which is to make full use of the space in the dock to build ships. The force of the floating cable at the moment of floating of the ship is affected by the seasonal wind direction. The tightness of the front and rear cables is different, in order to avoid the phenomenon of scratching between the whole ship and the half section, the whole ship and the dock door.

[0032] 2. The docking berth of the ship determines the undocking sequence of the undocked ships, so as to determine the hanging method of the fender and ball on the first undocked ship. The ball is attached to the ship to prevent the outer plates of the two ships from scratching each other due to the small gap between the two ships and the poor running posture of the two ships, resulting in damage to the outer plate paint and outer plate wrapping. The anti-collision ball when un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com