Angle detection tool and detection method thereof

A technology of angle detection and detection method, which is applied in the direction of angle/taper measurement, etc., can solve the problem of inability to measure the angle value, achieve high economic value and practical value, convenient manufacture, and low development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Taking the application of the present invention to measure the opening angle of the valve in the casing and the valve structure as an example, the present invention will be further described in detail.

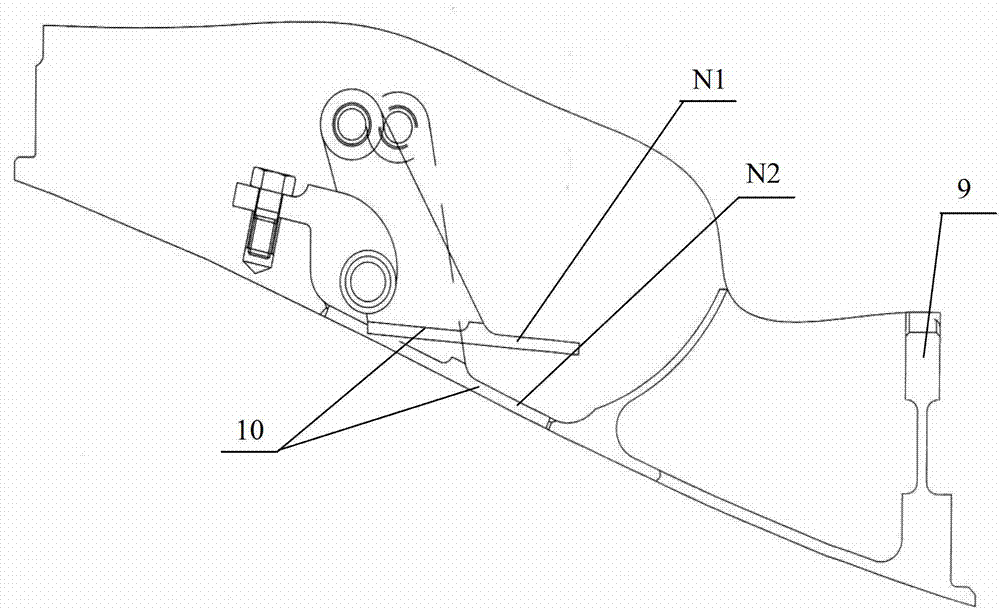

[0022] Such as figure 1 As shown, the tested part is composed of a fixed part and a rotating part, and the rotating part is fixed on the fixed part through the rotating shaft; that is, the tested part is a casing and a valve structure, the fixed part is the casing, the rotating part is the valve, and the valve passes through The rotating shaft is fixed on the casing. When working, the valve 10 is opened around the rotation axis 2 from the N2 closed state to the N1 open state. It is necessary to measure the angle 0°, 3°, 6° of the valve 10 from the N2 closed state to the N1 open state. .

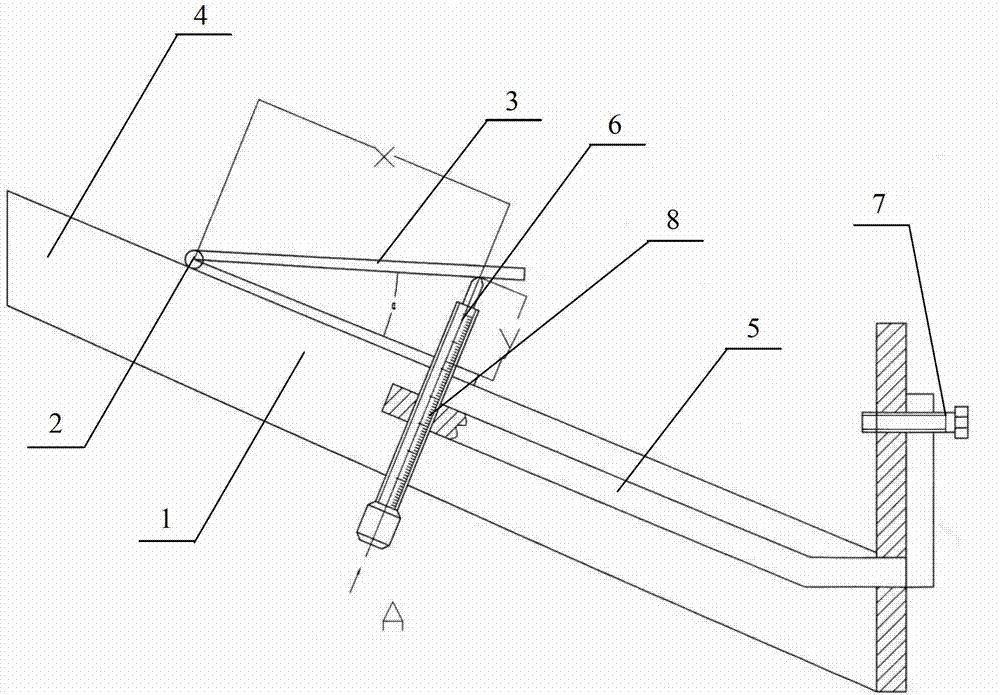

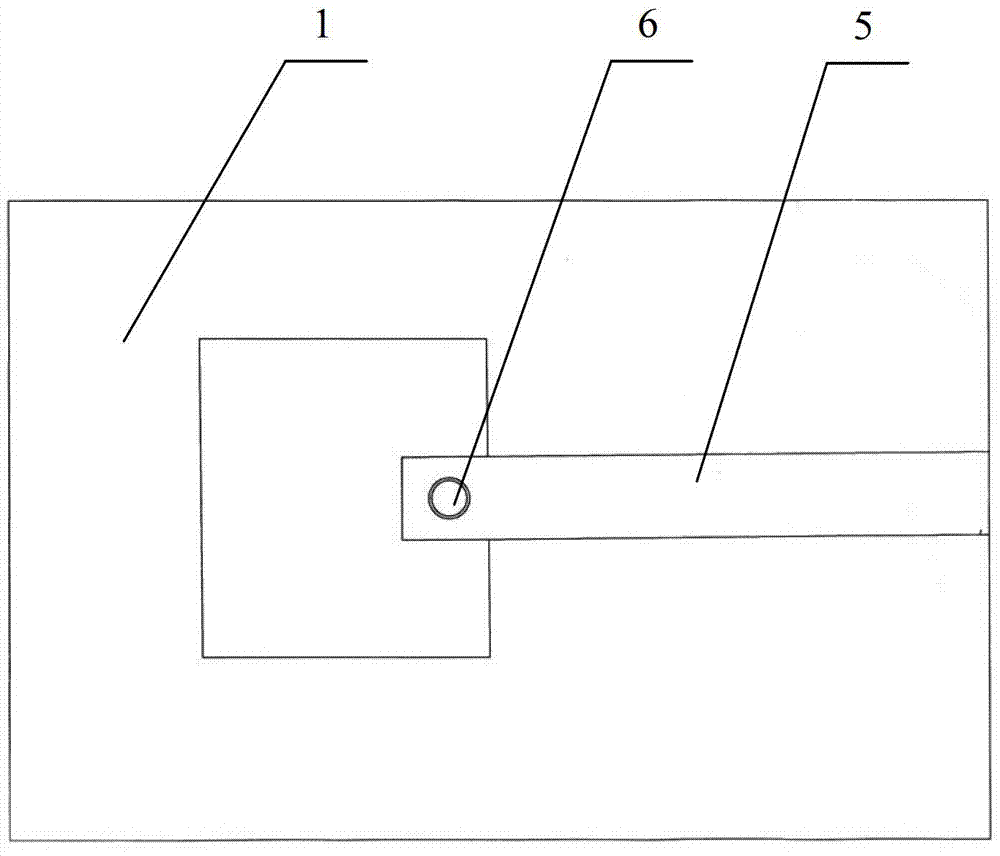

[0023] Such as figure 2 , image 3 As shown, an angle detection gauge includes a fixing device 5, and one end of the fixing device 5 is connected to a screw rod 6 through threads....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com