Triaxial test device

A triaxial test, friction device technology, applied in soil material testing, material inspection, etc., can solve problems such as axial deformation, and achieve uniform diameter changes and accurate stress calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

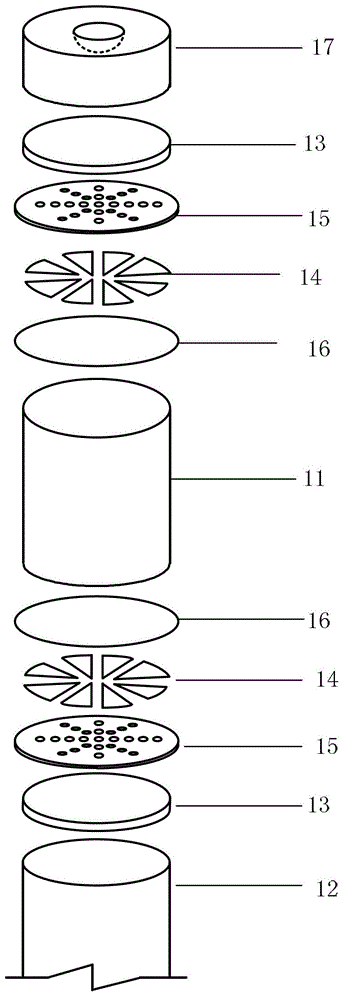

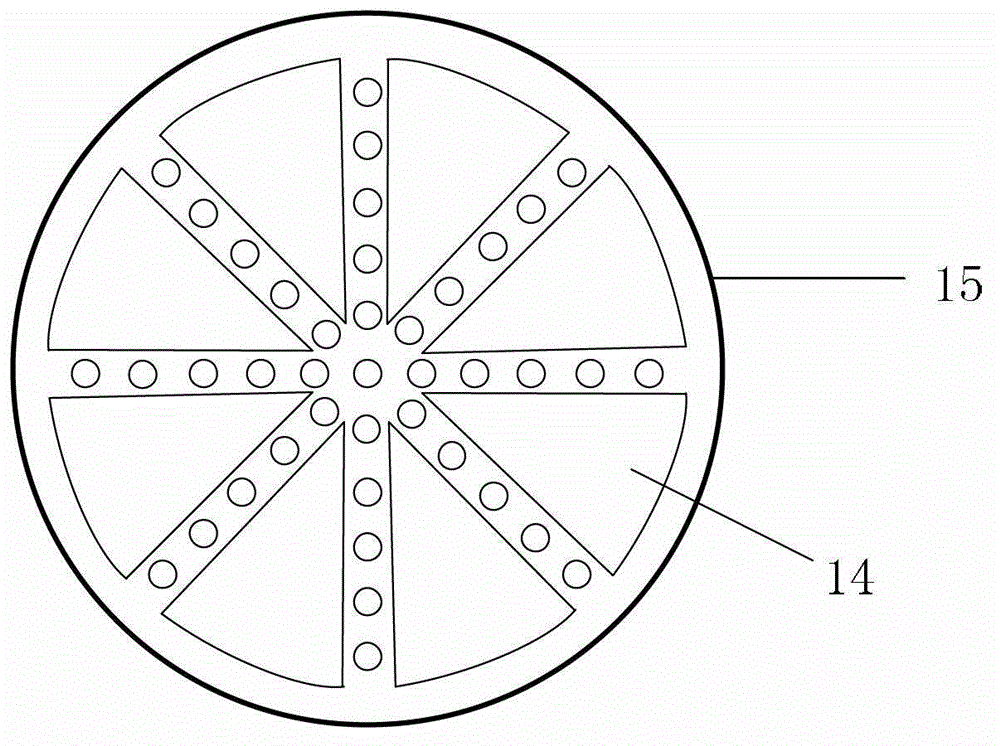

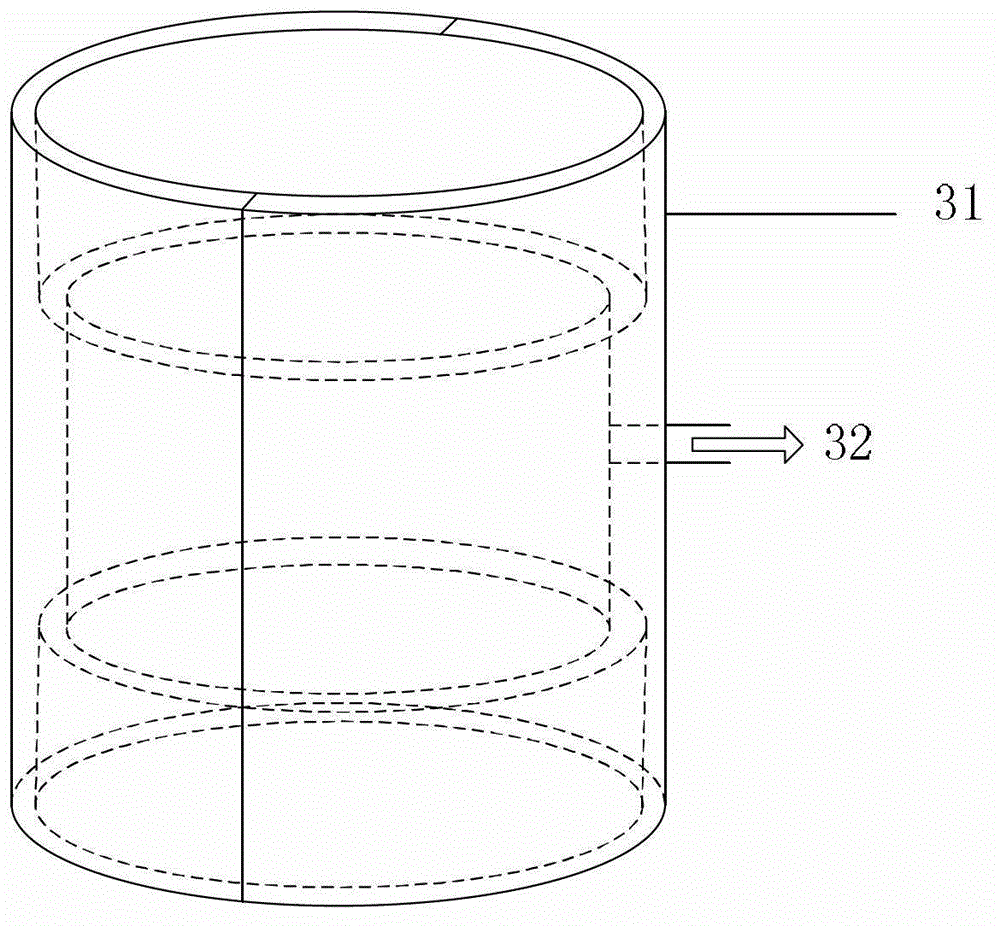

[0014] A triaxial test device proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

[0015] The core idea of the present invention is that, in the triaxial test device provided by the present invention, the elastic film arranged at both ends of the triaxial sample can slide relative to the anti-friction plate, thereby reducing or offsetting the lateral constraints on the two ends of the triaxial sample The friction force makes the two ends of the triaxial sample slide laterally when the axial force is applied, and finally makes the diameter change of the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com