Synaptic junction type handle structure

A synaptic, handle technology, applied in the direction of wing leaf handles, wing leaf handles, building structures, etc., can solve problems such as difficult to open and bulky doors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

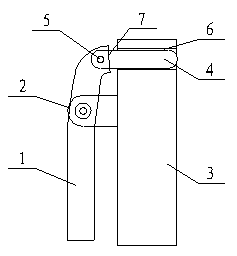

[0010] Such as figure 1 As shown, the synaptic handle structure described in the embodiment of the present invention includes a handle 1, a support block 2, a base 3 and a synapse 4, the support block 2 is fixed on the outer surface of the base 3, and the handle 1 is hinged on On the support block 2, the front end of the handle 1 is inclined inwardly, and is hinged to the synapse 4 through a hinge shaft 5 at the top of the handle. The synapse 4 runs through the base 3, and the length of the synapse 4 is greater than the thickness of the base 3 , the base 3 is provided with a chute 6 matching with the synapse 4, the top of the handle has an inclined slope 7, the distance from the hinge shaft 5 to the support block 2 is smaller than the distance from the tail of the handle 1 to the support block 2 1 / 3 of the distance, the width of the slope 7 at the top of the handle is greater than the width of the chute 6 .

[0011] When the handle is twisted outward to the maximum limit, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com