Quadrature calibration method and device of triaxial vector magnetometer

A technology of calibration device and calibration method, which is applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of low calibration degree and inability to meet high-precision vector magnetic field detection, etc., so as to improve axial alignment accuracy and improve Orthogonality measurement accuracy, the effect of avoiding magnetic field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

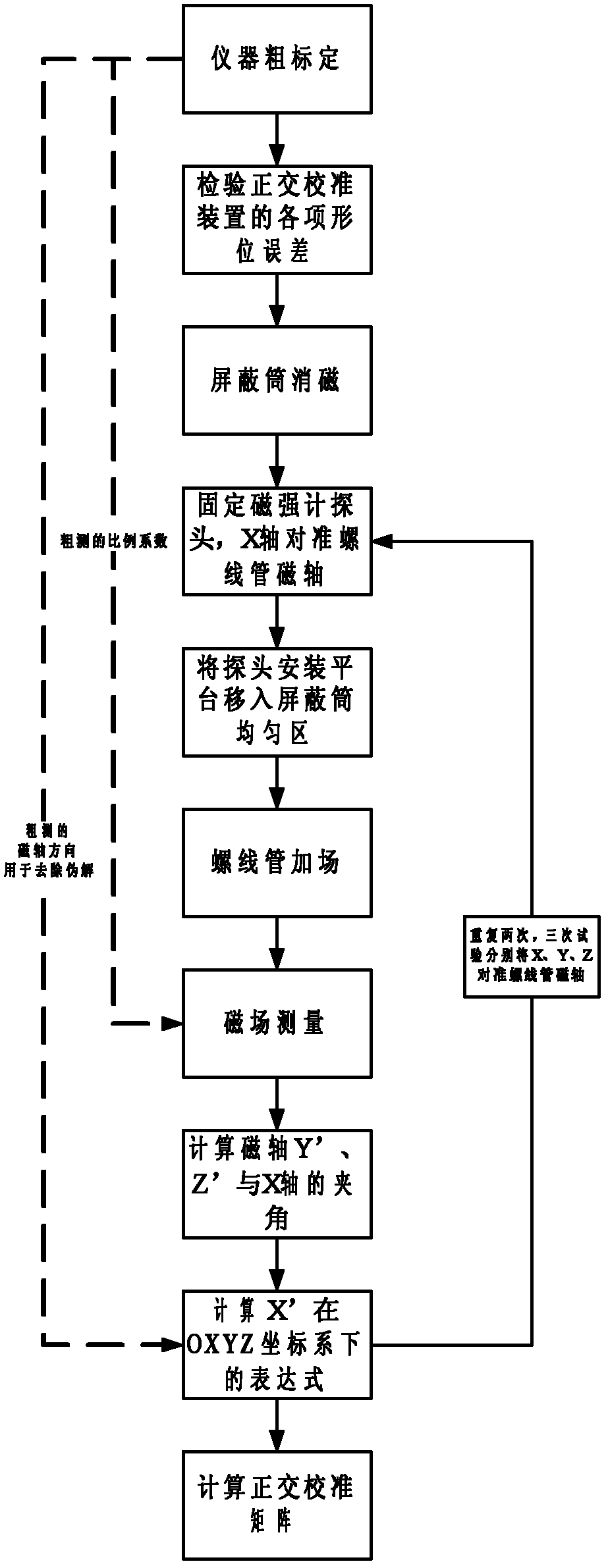

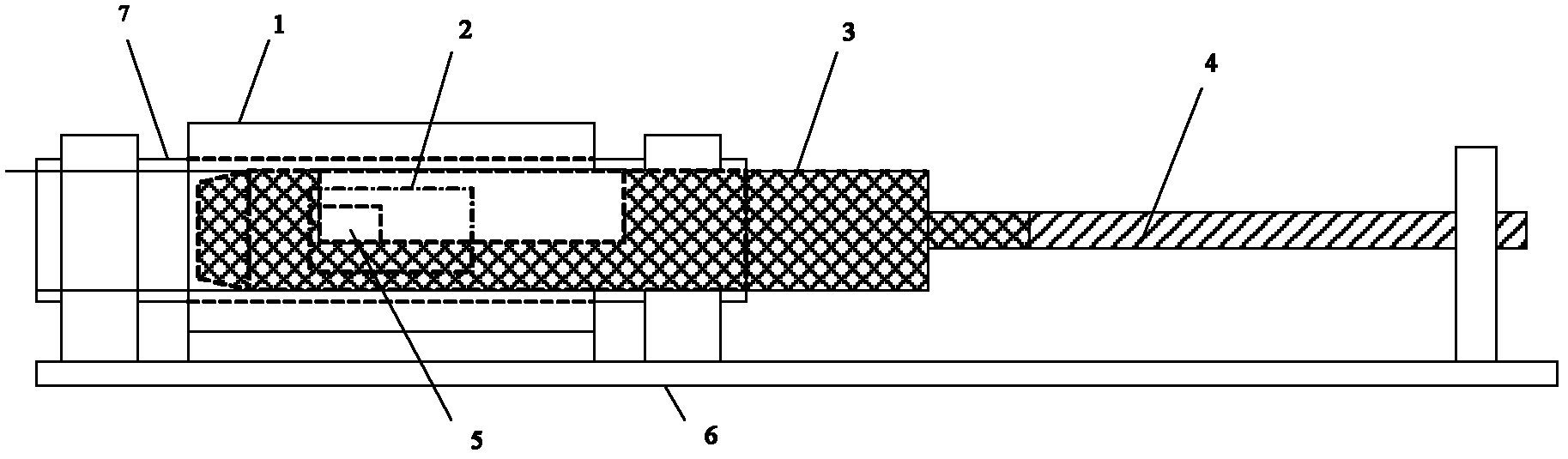

[0044] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

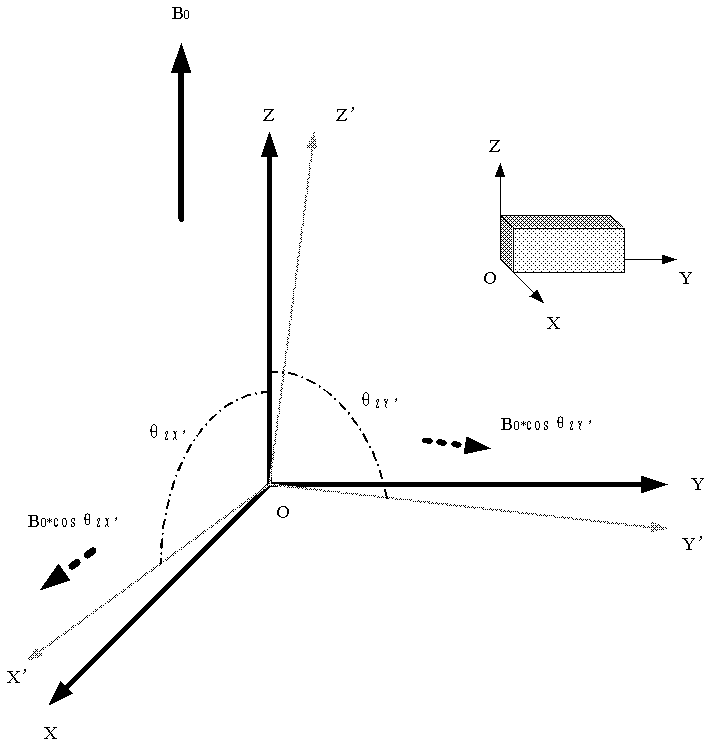

[0045] The invention realizes the alignment between the reference direction of the probe and the direction of the external magnetic field by virtue of the precision-processed solenoid and the fixed tooling of the probe, and overcomes the difficulty that the error cannot be controlled by adjusting the alignment manually or by means of a non-magnetic turntable in the past. The mechanical axis of the three-axis vector magnetometer probe, that is, the axis of the coordinate system of the magnetometer probe structure, is used as the reference direction of the probe, so that the calibrated vector magnetic field direction can be measured.

[0046] Explanation of several terms in the present invention: Probe structure coordinate system: the external nominal of the three-axis vector magnetometer probe, the orthogonal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com