Rotary ring adjustor and usage thereof

A level adjuster and rotating ring technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as downtime, high manpower consumption, and the rotation ring is not kept level, so as to reduce manpower, solve downtime problems, and ensure The effect of normal and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

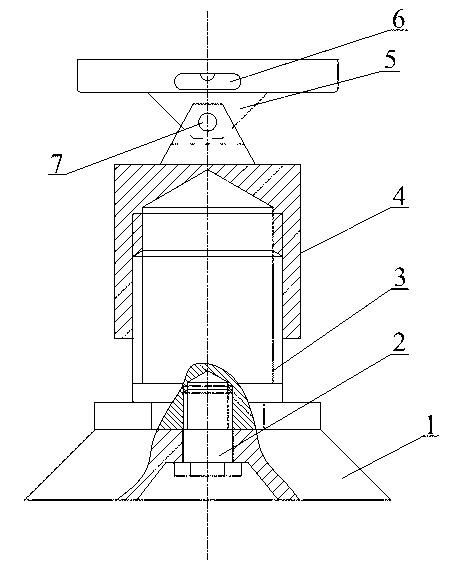

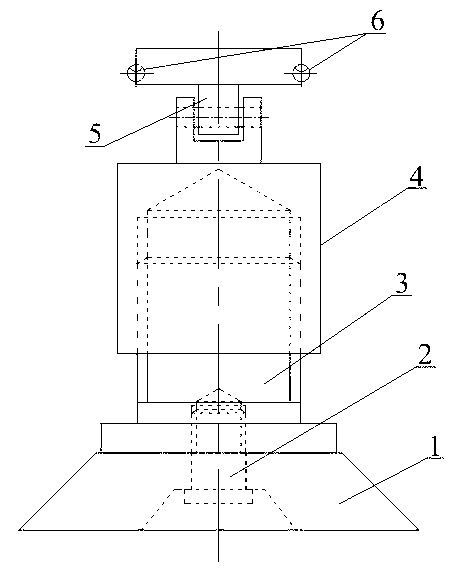

[0021] like figure 1 , 2 As shown, the rotary ring level adjuster includes the adjuster support 1, which is connected with the adjuster support 1 and is located above the adjuster support 1 and can rotate the adjustment bolt 3, which is set above the adjustment bolt 3 at the level of its threaded connection. The regulator housing 4 , the balance bracket 5 arranged above the level regulator housing 4 and connected to it through cylindrical pins 7 , and the bubble level 6 arranged on the balance bracket 5 .

[0022] In order to ensure that the adjustment bolt rotates to adjust the height of the present invention and whether the balance bracket is horizontal, the adjustment support will not rotate together with the adjustment bolt, so the center of the adjustment support 1 is also provided with a through hole, and through the through hole The connecting bolt 2 is connected with the adjusting bolt 3; the connecting bolt is connected with the adjusting thread through threads. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com