A device capable of forward and reverse contact and variable stroke

A technology of positive and negative strokes, applied in the direction of contact operating parts, etc., can solve the problems of insufficient versatility, and achieve the effect of reliable and durable structural characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

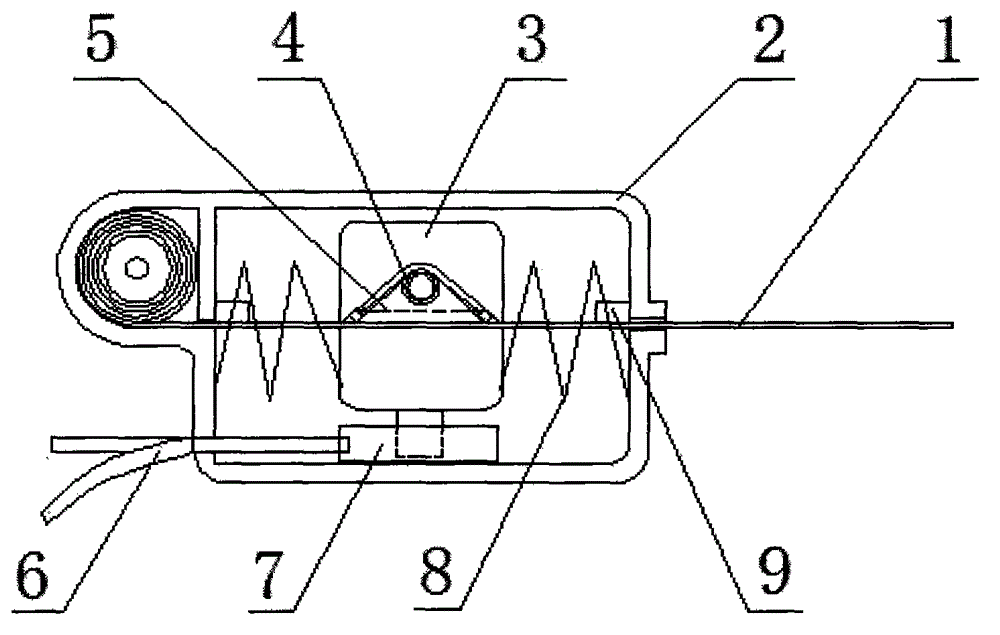

Embodiment 1

[0022] Embodiment 1: It is applied to the occasion where it is connected with the mechanism device that needs to obtain the signal and then moves accordingly. This example is used to obtain the movement signal of the door opening in the vehicle; it solves the problem that the movement stroke of the door lock lever of each model is different and the installation point is difficult to choose problem; if the motion signal can be obtained bidirectionally, the installation point will not be a problem. as attached figure 1 As shown, it includes a reciprocating action part 1, a housing part 2, a bidirectional stop member 3, a locking torsion spring 4, a sliding boss 5, an outer lead 6, a conductor part 7, a return spring 8 and an unlocking part 9. Described reciprocating action part 1, is to take thickness 0.5 millimeter, the spring steel sheet of width 2 millimeters is formed into clockwork disk shape, and the device of the straight bar shape of outer leading end is long 50 millimet...

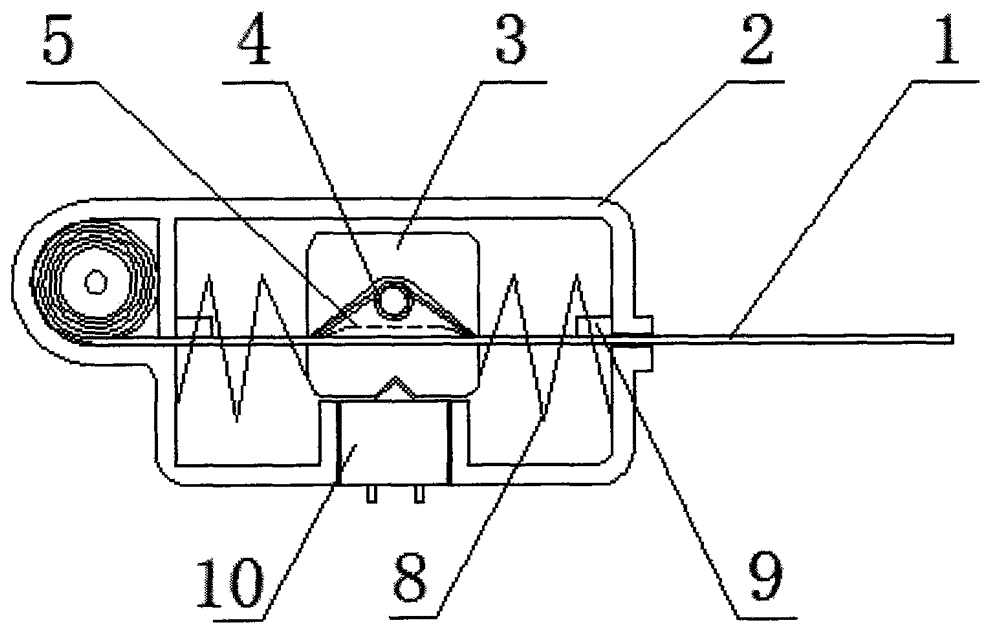

Embodiment 2

[0023] Embodiment 2: as attached figure 2As shown, it includes a reciprocating action part 1 , a housing part 2 , a bidirectional stop member 3 , a locking torsion spring 4 , a sliding boss 5 , a return spring 8 , an unlocking part 9 and a contact switch 10 . The said reciprocating element 1 is consistent with the first embodiment. The housing part 2 is provided with a fixed cavity for the touch switch 10 at the lower part as shown in the figure; the rest of the arrangement is consistent with that of the first embodiment. The two-way stop member 3 , as shown in the figure, has the same upper part as that in Embodiment 1; the lower part is provided with a concave triangular structure for conducting the contact switch 10 . The locking torsion spring 4 , sliding boss 5 , return spring 8 and unlocking member 9 are consistent with the first embodiment. The touch-on switch 10 uses two Alps SPVL series 3-Wag three-way action switches, which are arranged side by side on the cavity ...

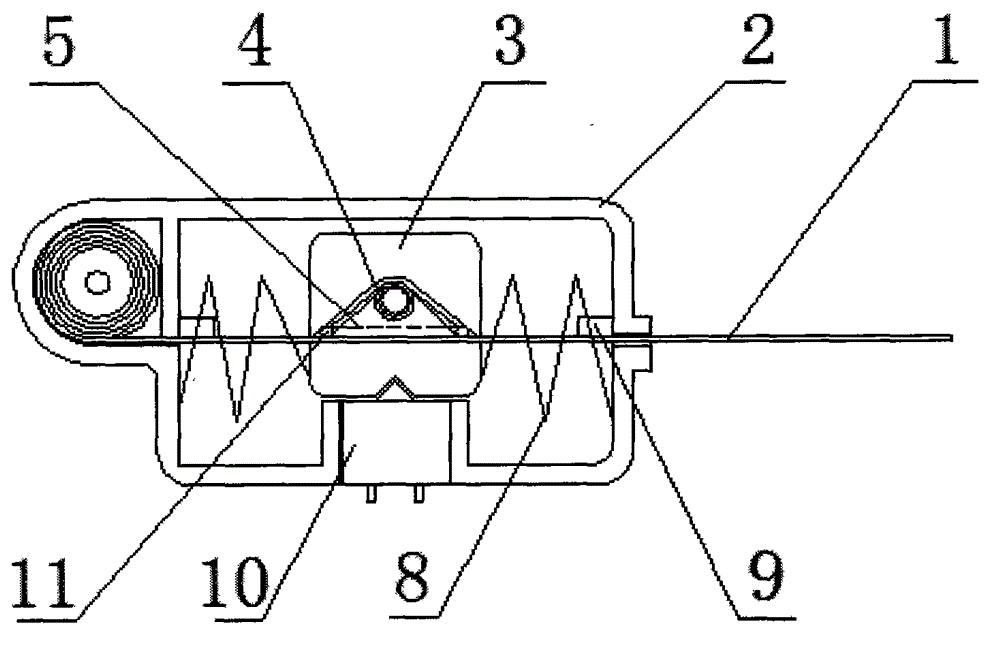

Embodiment 3

[0024] Embodiment 3: as attached image 3 As shown, it includes a reciprocating action part 1, a housing part 2, a two-way stop member 3, a locking torsion spring 4, a sliding boss 5, a return spring 8, an unlocking part 9, a contact switch 10 and a locking part 11 . The reciprocating action part 1 and the housing part 2 are consistent with the second embodiment. The two-way stop member 3, as shown in the figure, has a movable groove-shaped cavity of the locking piece 11 on the top of the double-action piece 1, which is bidirectionally symmetrical and conical, and the rest is the same as that of the embodiment 2 agree. The locking torsion spring 4 , return spring 8 , unlocking member 9 and contact switch 10 are consistent with the second embodiment. Owing to being provided with locking part 11, realize its effect to shorten the length of above-mentioned example sliding boss 5 and improve its position height. The locking member 11 is made of a PC material ball with a diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com