Power tool

A technology for working tools and tools, applied in the direction of manufacturing tools, wood processing appliances, metal processing, etc., can solve problems such as inability to use and increase the cost of bearing manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

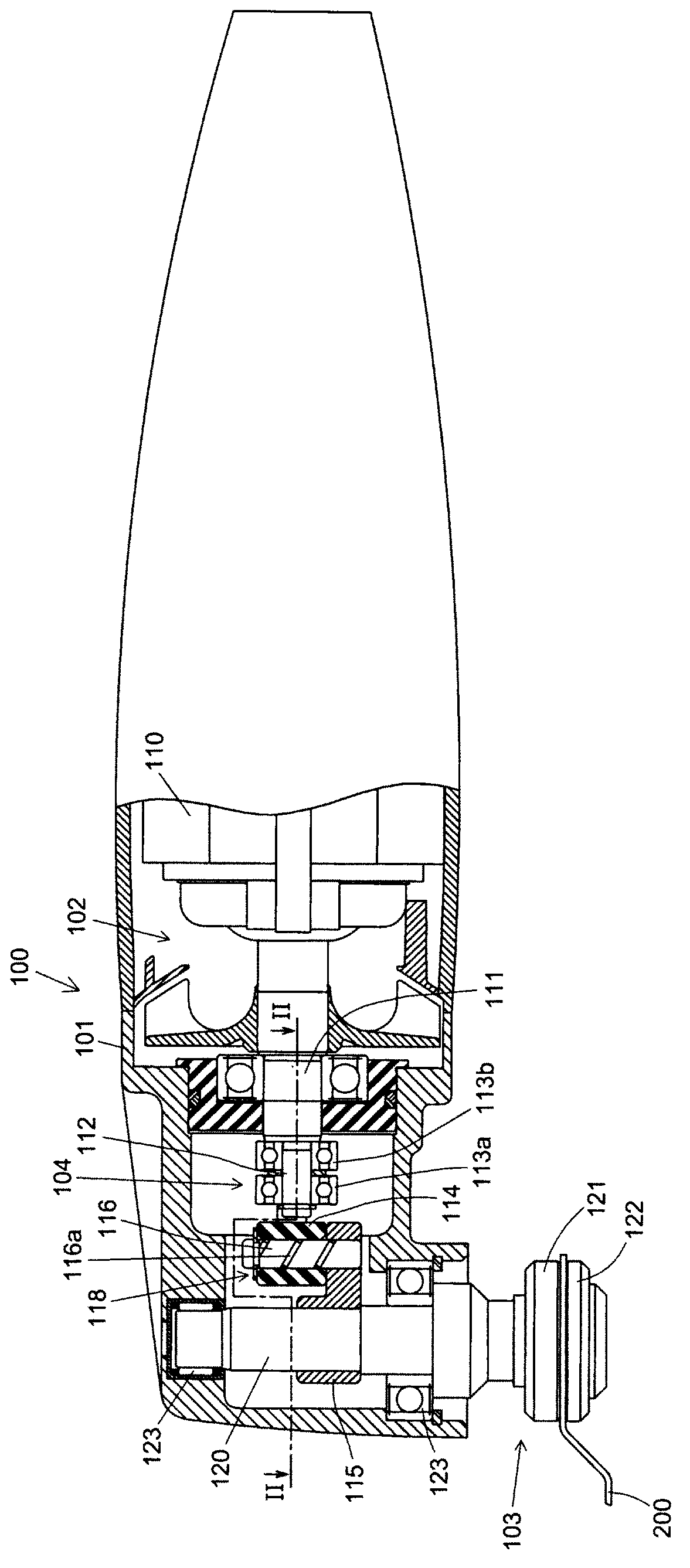

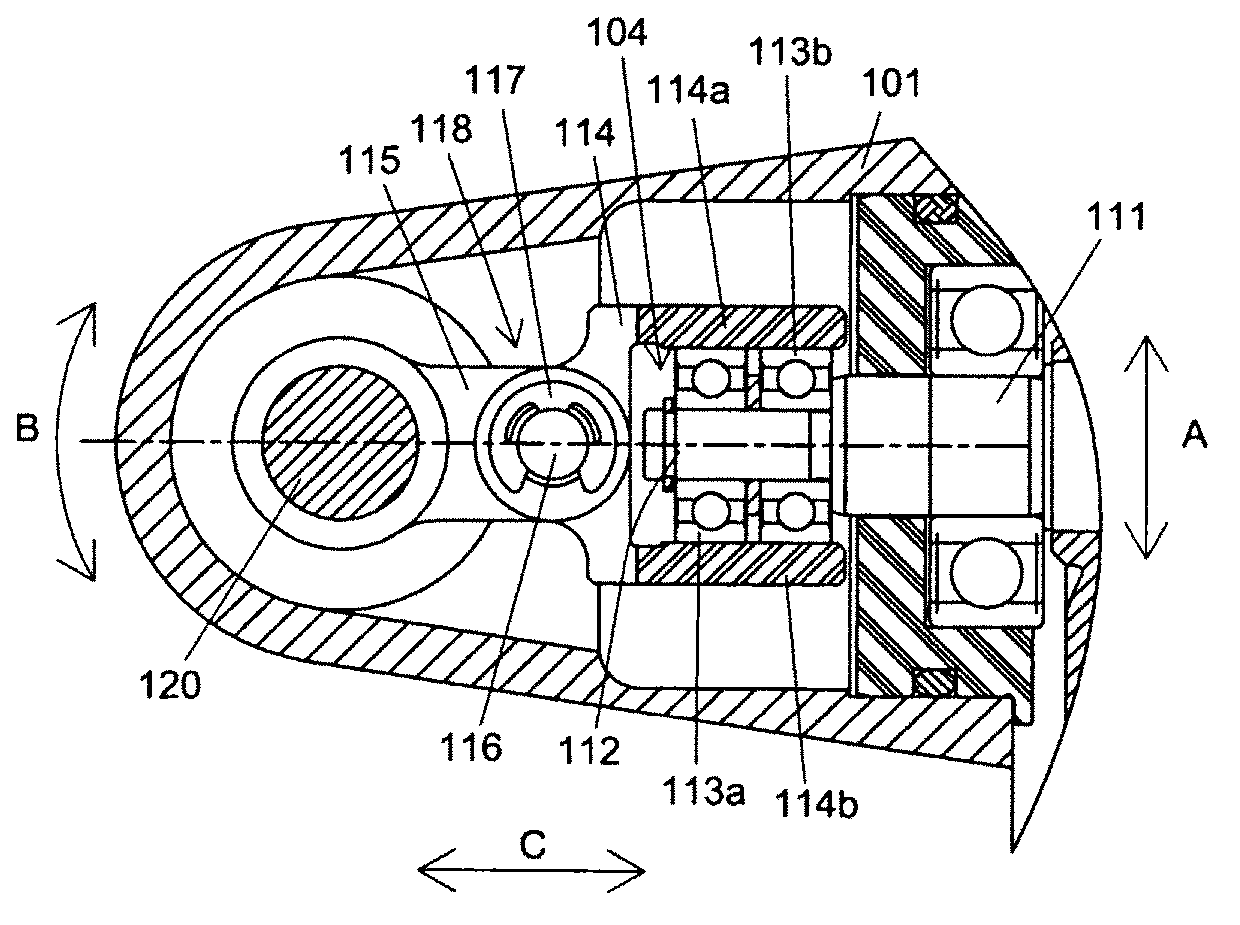

[0030] Refer below Figure 1~Figure 3 The first embodiment of the present invention will be described in detail. In this embodiment, the working tool of the present invention will be described by taking an electric vibration tool as an example.

[0031] Such as figure 1 As shown, the electric vibration tool 100 is a work tool that can perform processing operations such as cutting and grinding on a workpiece according to the type of processing tool (working part) installed, and a blade or grinding blade can be selectively installed on it. Various processing tools such as pads can vibrate (slightly oscillate) the installed processing tools to perform processing operations. In this embodiment, the blade 200 will be described as an example of a machining tool. In addition, processing tools such as the blade 200 have an embodiment structure corresponding to the "tip tool" in the present invention.

[0032] Such as figure 1 , figure 2 As shown, the electric vibration tool 100...

no. 2 Embodiment approach )

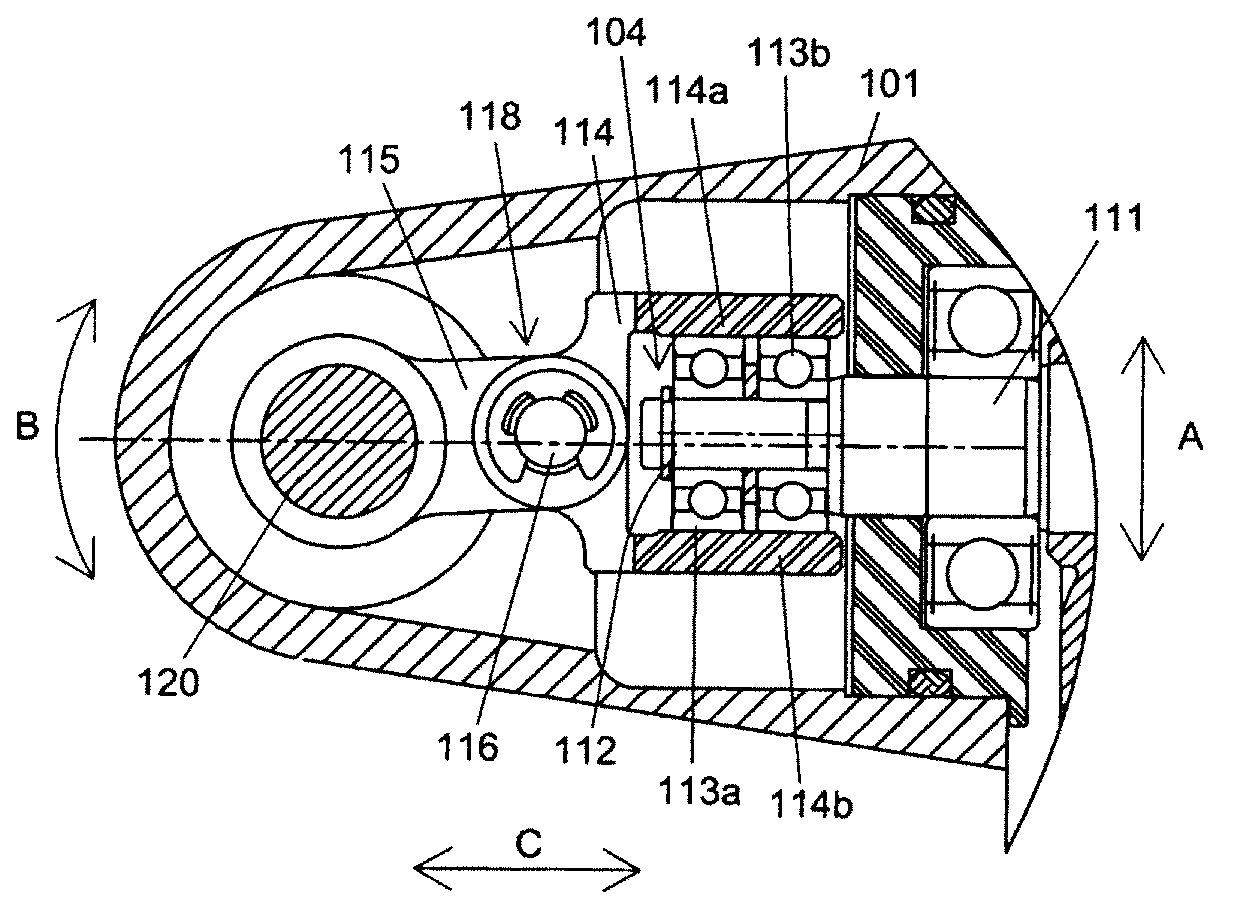

[0048] Refer below Figure 4~Figure 6 A second embodiment of the present invention will be described in detail. Compared with the first embodiment, the second embodiment is different in the structure related to the driven arm, the main shaft connection arm, and the bearing, and the other structural elements are the same as those of the first embodiment.

[0049] Such as Figure 4 As shown, in the second embodiment, only one bearing 213 is provided. Additionally, if Figure 5 , Figure 6 As shown, the follower arm 214 has a first arm portion 214 a and a second arm portion 214 b, and is disposed outside the bearing 213 so as to be able to contact the bearing 213 . In the direction from the side of the eccentric moving part 104 constituted by the eccentric shaft 112 and the bearing 213 to the side of the main shaft 120 ( Figure 5 In the C direction), the connecting part for connecting the driven arm 214 and the main shaft connecting arm 215 is arranged in parallel with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap