Conducting ring brush wire contact pressure detection method and device

A technology of contact pressure and detection method, applied in the direction of measuring the force applied to the control element, etc., which can solve the problems of high labor intensity and visual impairment of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

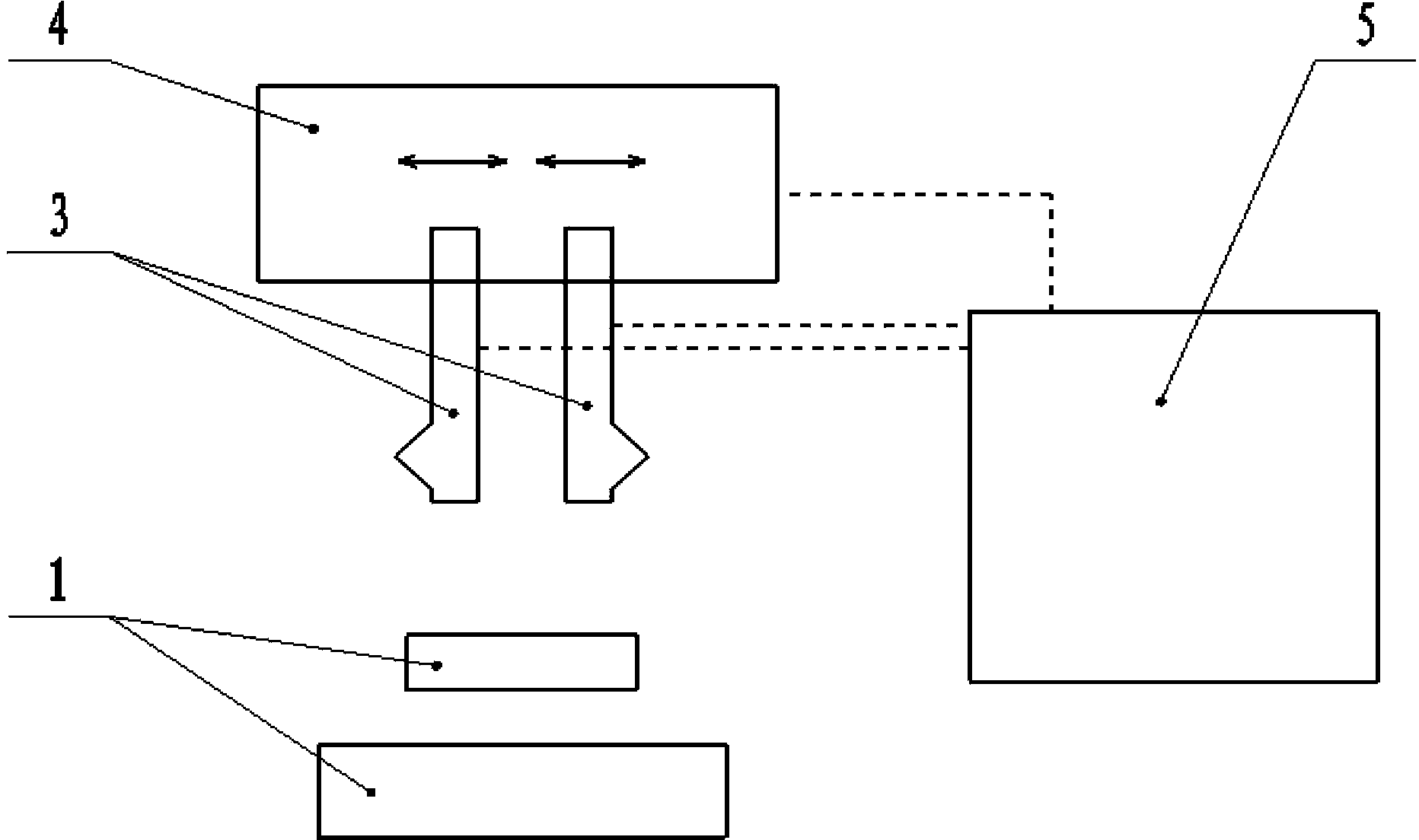

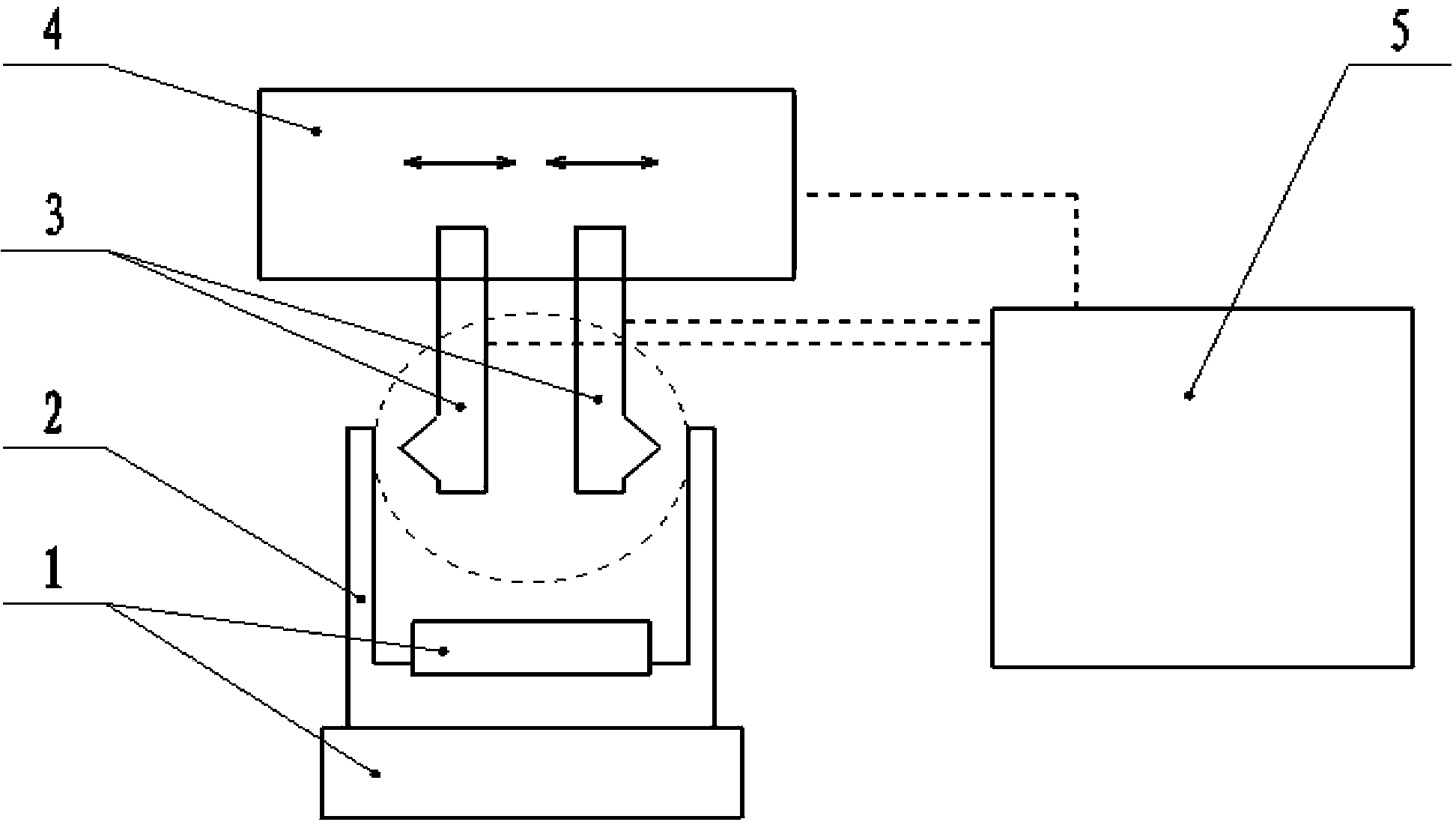

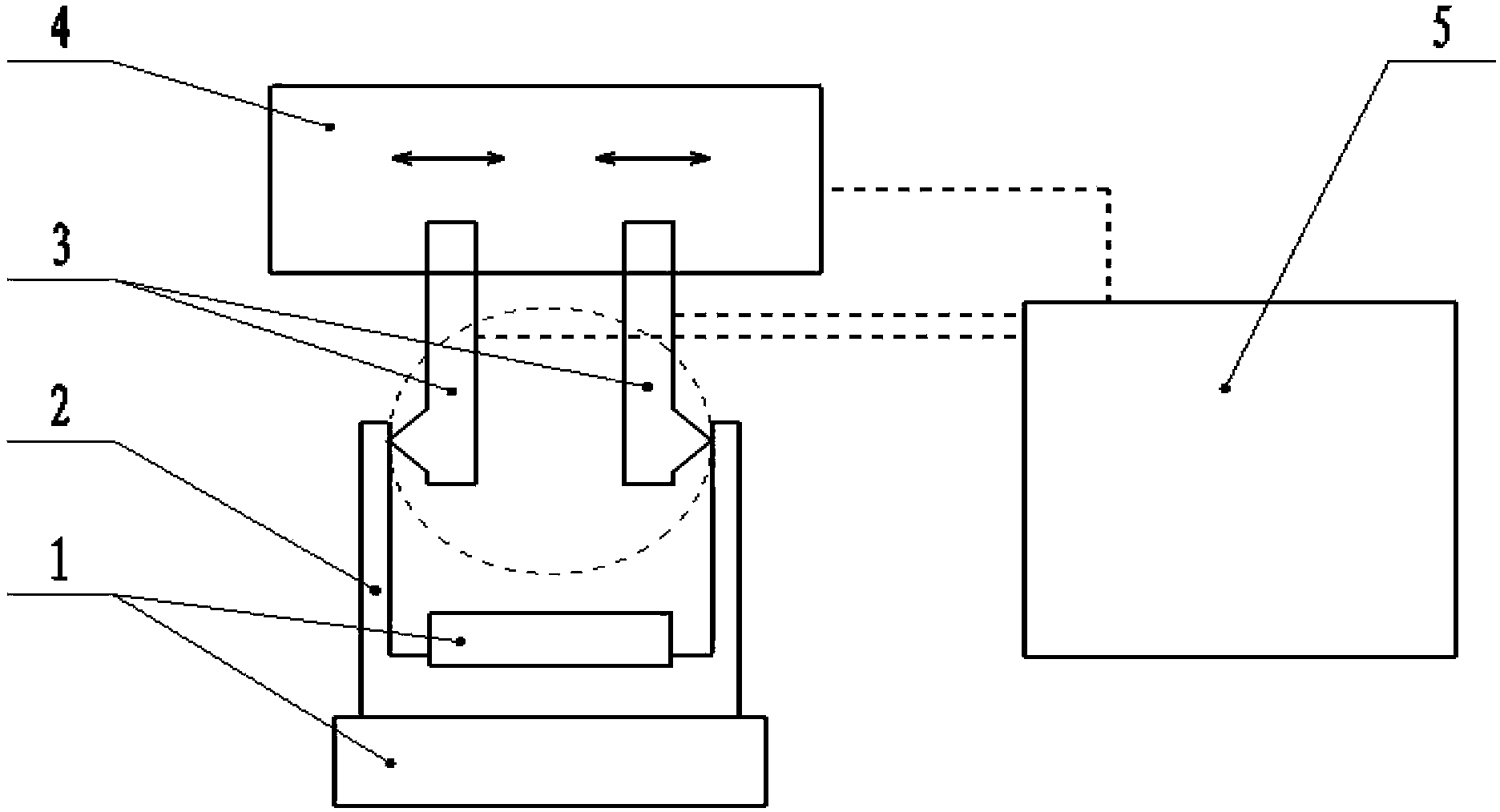

[0019] The present invention will be further described below with reference to the accompanying drawings.

[0020] A method for detecting the contact pressure of a conductive ring brush wire, the steps are:

[0021] 1) Make a special standard gauge block 2 that is consistent with the key dimensions of the tested conductive ring brush 6;

[0022] 2) Install the special standard gauge block 2 made in step 1) on the fixture tooling 1;

[0023] 3) Use the linear displacement positioning mechanism 4 to position the force-measuring sensor probe 3 to the position where it is in contact with the special standard gauge block 2, which is the working contact position of the brush wire of the conductive ring brush 6 to be tested, and record the position ; After recording the position, separate the force measuring probe 3 from the special standard gauge block 2;

[0024] 4) Remove the special standard gauge block 2, and then install the tested conductive ring brush 6 on the fixture tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com