A furrow plow for asparagus

A ditching plough and asparagus technology, which is applied in the direction of excavation/covering of ditch holes, planting methods, application, etc., can solve the problem that the depth of ditching and the width of ditch bottom are difficult to meet the requirements, the ditching resistance is large, and the work efficiency is low. and other problems, to achieve the effect of flexible and controllable trenching depth and trench bottom width, good structural stability and improved trenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

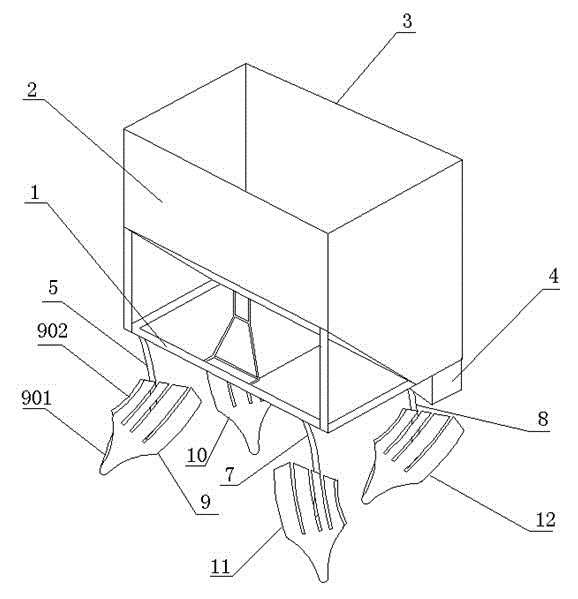

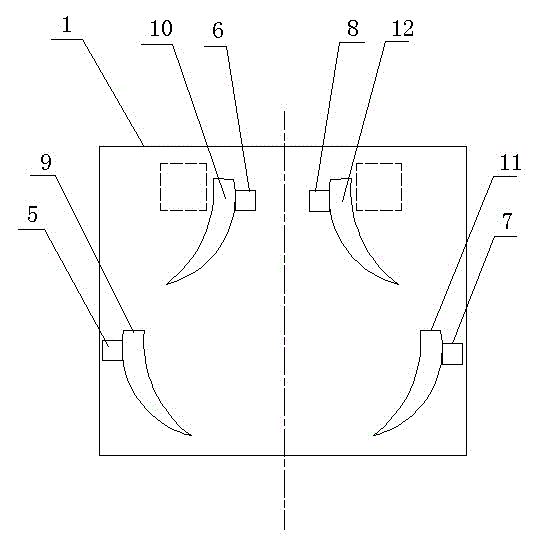

[0019] Such as figure 1 and 2 Shown, a kind of asparagus furrowing plow comprises plow frame 1, plow post and plow body, and described plow post includes front plow post and rear plow post, and described plow body includes front plow and rear plow, and front plow post It is arranged on the front of the plow frame, and the rear plow column is arranged on the rear of the plow frame. The front plow and the rear plow are respectively installed on the front plow column and the rear plow column. The plow frame is preferably rectangular; It is arranged in double rows, that is, it includes two sets of front plows and rear plows with the same arrangement. Specifically, the front plow column includes the first front plow column 5 and the second front plow column 7, and the rear plow column includes the first rear plow column 6 ( figure 1 not shown in ) and the second rear plow column 8, the front plow includes the first front plow 9 and the second front plow 11, the rear plow includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com