Construction technology of corrugated steel web post-welding shrinkage prestressed composite structure

A technology of corrugated steel webs and composite structures, which is applied to the direction of long-strip structural members, structural elements, building components, etc. for load-bearing, can solve the problems of shelling of steel plates and concrete, flange plates cannot shrink, etc., and achieve reduction Effect of Concrete Shrinkage Cracks and Reduction of Stress Redistribution in Composite Structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

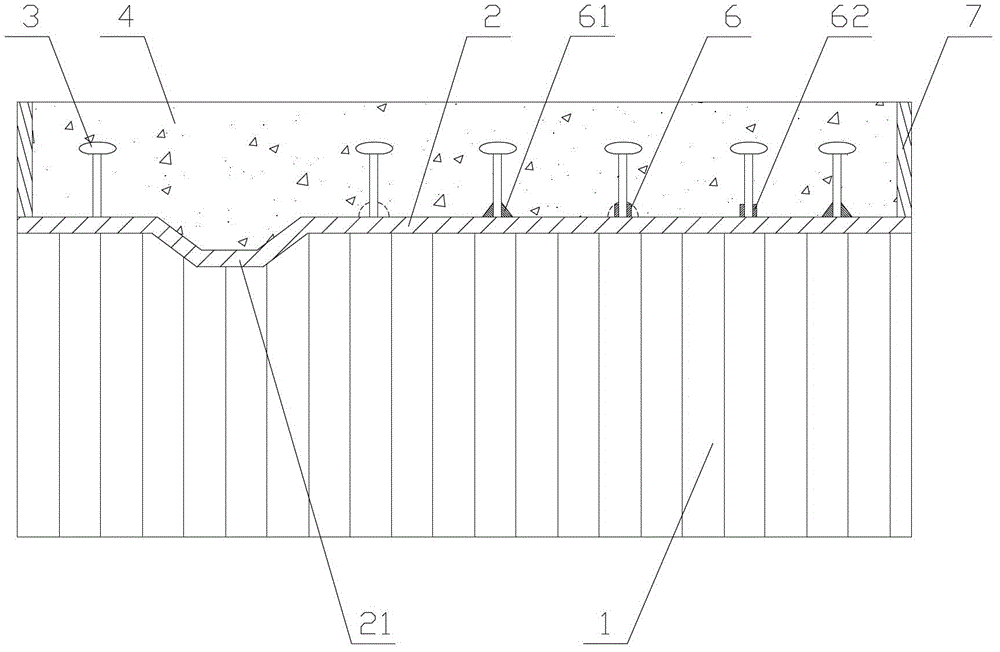

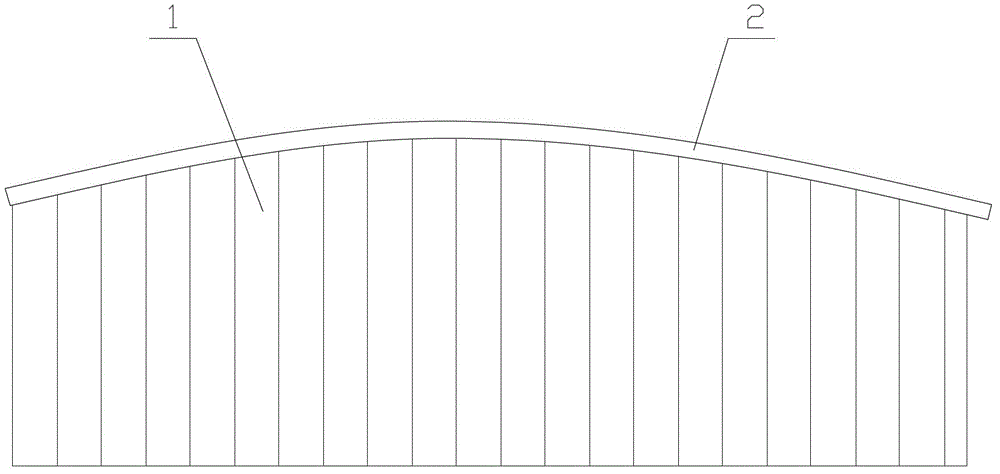

[0021] The construction technology of the post-welded shrinkage prestressed composite structure of the corrugated steel web, such as figure 1 As shown, it includes the corrugated steel web 1, the flange plate 2, and the concrete 4, including the following steps: A. Partially weld the corrugated steel web 1 and the flange plate 2; B. Pouring concrete on the flange plate 2; C , The corrugated steel web 1 and the flange plate 2 are integrally welded.

[0022] The partial welding in step A is not a complete welding, but spot welding or spaced spot welding to connect the corrugated steel web 1 and the flange plate 2 together, so that they will not fall off during installation and transportation. That is, the welding workload is small. The flange plate 2 is welded to the corrugated steel web 1 and the flange plate 2 is combined with the concrete 4. First of all, in the prior art, most of the flange plates and webs are completely welded and transported to the construction site, and then...

Embodiment 2

[0027] The difference between this embodiment and the first embodiment is that a micro strain wave 21 is provided on the flange plate 2. The flange plate 2 has a micro-shaped strain wave 21, and the two ends of the flange plate 2 are welded with a limited end plate 7. Limiting end plates 7 are arranged at both ends of the beam. By setting micro-shaped strain waves 21 on the flange plates, compared with the straight flange plate in the prior art that cannot contract longitudinally, the flange with micro-strain waves The plate 2 can shrink together with the concrete in the longitudinal direction, and the corrugated steel plate connected with the flange plate 2 has a certain longitudinal shrinkage capacity. Therefore, in the entire composite structure: the concrete, the flange plate, and the corrugated steel plate shrink together to make The entire structure can work in concert to achieve a completely combined state. The wave height of the micro-shaped strain wave 21 is less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com