Combined structural-welding contracting connection structure and construction process

A combination structure and connection structure technology, which is applied to the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of steel plates and concrete peeling, flange plates cannot shrink, concrete cracks, etc., to achieve Avoid shrinkage cracks, reduce stress redistribution phenomenon, and increase the effect of longitudinal expansion and contraction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

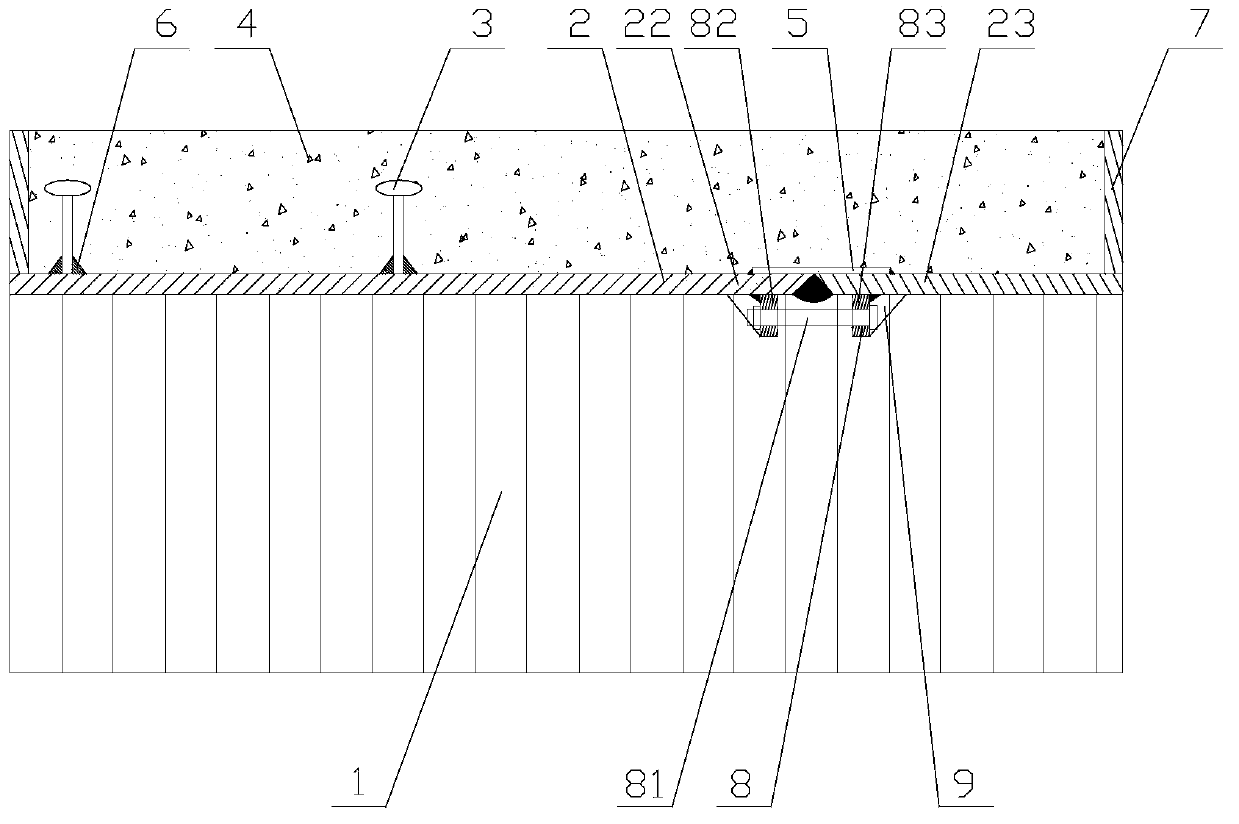

[0022] Combined structure Welded shrinkage connection structure, such as figure 1 As shown, it consists of corrugated steel web 1, flange plate 2, and concrete 4. One side of the flange plate 2 is welded with the corrugated steel web 1, and the other side is combined with concrete 4. The flange plate 2 is segmented. Open type, comprise left flange plate 22 and right flange plate 23, be welded with connecting strap 5 between left flange plate 22 and right flange plate 23, left flange plate 22 and right flange plate 23 are connected by welding. One end of the connecting strap 5 is welded to the left flange plate 22 or the right flange plate 23, and the other end is not welded, which can ensure the horizontal sliding of the flange plate 2 when it shrinks.

[0023] The two ends of the flange plate 2 are welded with a limiting end plate 7 . The connecting strap 5 is welded on the side where the flange plate 2 and the concrete 4 are connected. The connecting board also plays the r...

Embodiment 2

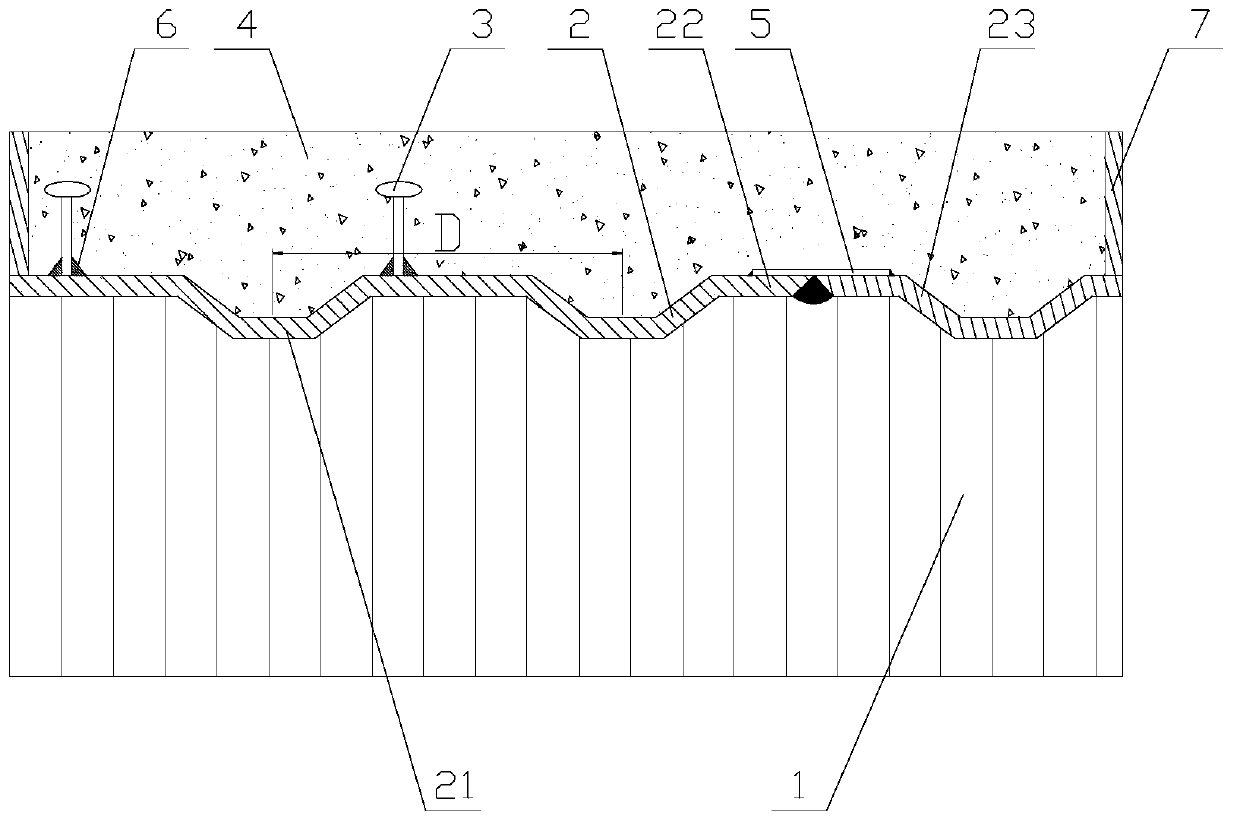

[0029] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the distance between the left flange plate 22 and the right flange plate 23 is 16mm, and the left flange plate 22 and the right flange plate 23 at the disconnection are provided with a single-sided cutout. The left flange plate 22 is provided with a left bolt end plate 82, and the right flange plate 23 is provided with a right bolt end plate 83, and the left bolt end plate 82 and the right bolt end plate 83 are connected by high-strength bolts 81. Before the left flange plate 22 is welded to the right flange plate 23, bolts are used to reduce the disconnection distance between the left flange plate 22 and the right flange plate 23, and then welding is performed. The single-sided slit is used for welding the left flange plate 22 and the right flange plate 23 . Since the left flange plate 22 is provided with a left bolt end plate 82 and the right flange plate 23 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com