Swill barrel

A technology for swill buckets and bucket lids, which is applied in the field of public health applications and can solve problems such as inclusions, difficulty in removal, and strange smells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

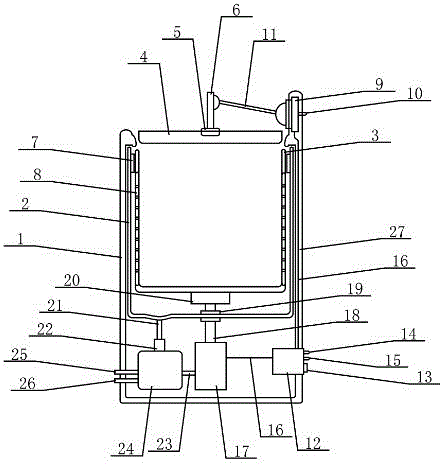

Embodiment 1

[0017] When processing the swill in the de-juicing tank, the restaurant staff presses the de-juicing control switch, the circuit control device starts to work according to the set program, and first sends current to the bung cover control device to ensure that the bung cover control device controls the bung cover. In the closed position; then send current to the power device, the power device starts to work according to the set program, the power output by the power device is sent to the rotating device through the power output shaft, and the rotating device drives the dejuicing barrel to rotate rapidly; under the centrifugal force Under the action, the juice in the swill is thrown out to the cavity wall between the de-juicing barrel and the inner barrel through the stainless steel filter plate, and flows along the cavity wall into the cavity between the de-juicing barrel and the bottom of the inner barrel.

Embodiment 2

[0019] When processing the swill in the de-juicing tank, the restaurant staff presses the de-juicing control switch, the circuit control device starts to work according to the set program, and first sends current to the bung cover control device to ensure that the bung cover control device controls the bung cover. In the closed position; then send current to the power device, the power device starts to work according to the set program, the power output by the power device is sent to the rotating device through the power output shaft, and the rotating device drives the dejuicing barrel to rotate rapidly; under the centrifugal force Under the action, the juice in the swill is thrown out to the cavity wall between the dejuicing barrel and the inner barrel through the carbon steel filter plate, and flows along the cavity wall into the cavity between the dejuicing barrel and the bottom of the inner barrel.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap