Zero-point energy power machine

A mechanical and dynamic technology, applied in the field of zero-point energy dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

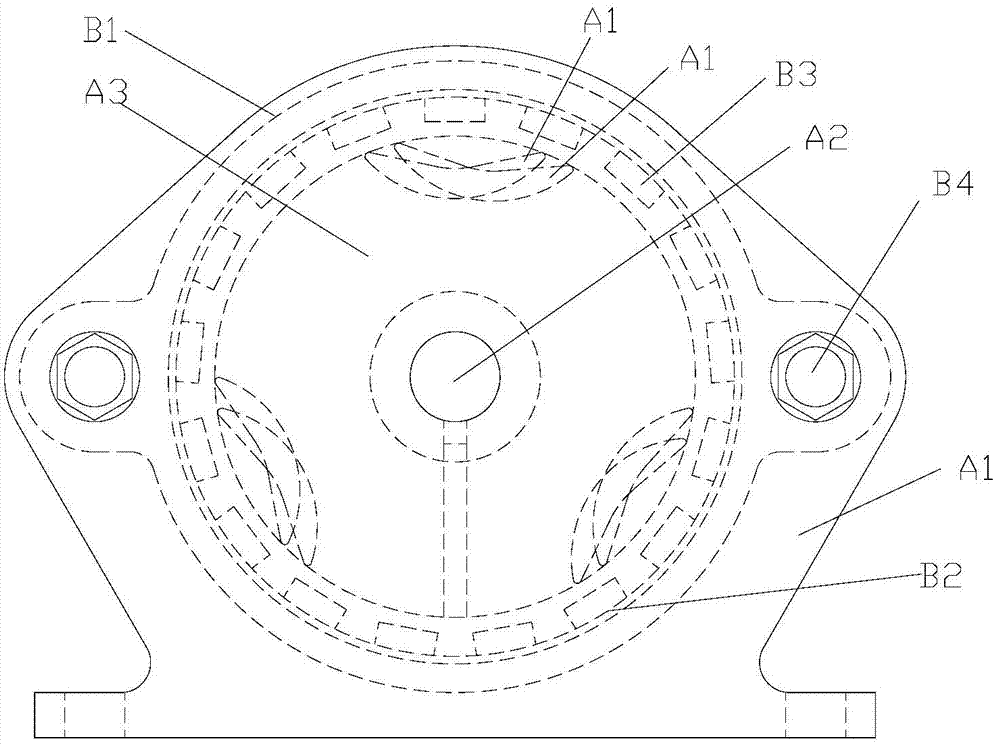

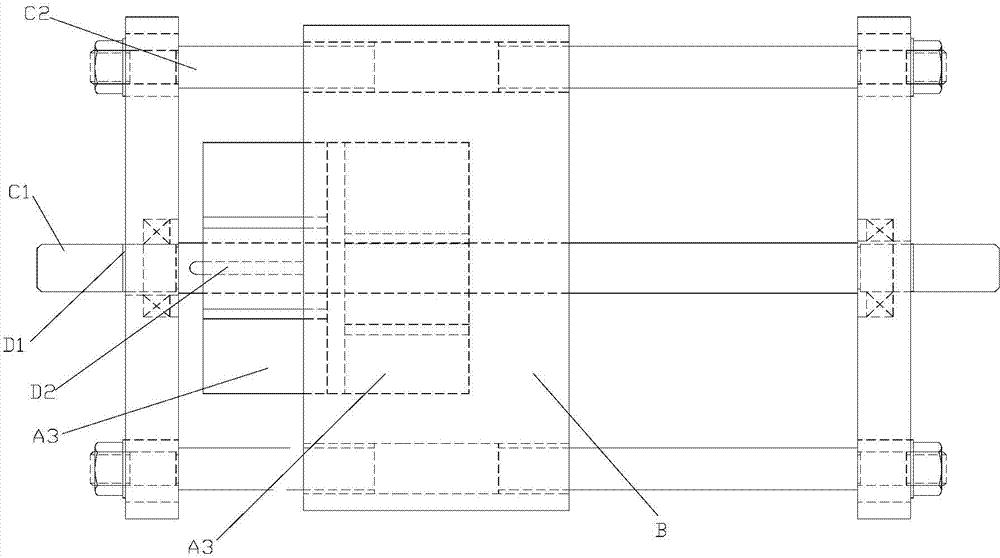

[0022] An embodiment of the present invention provides a zero-point energy power machine, including:

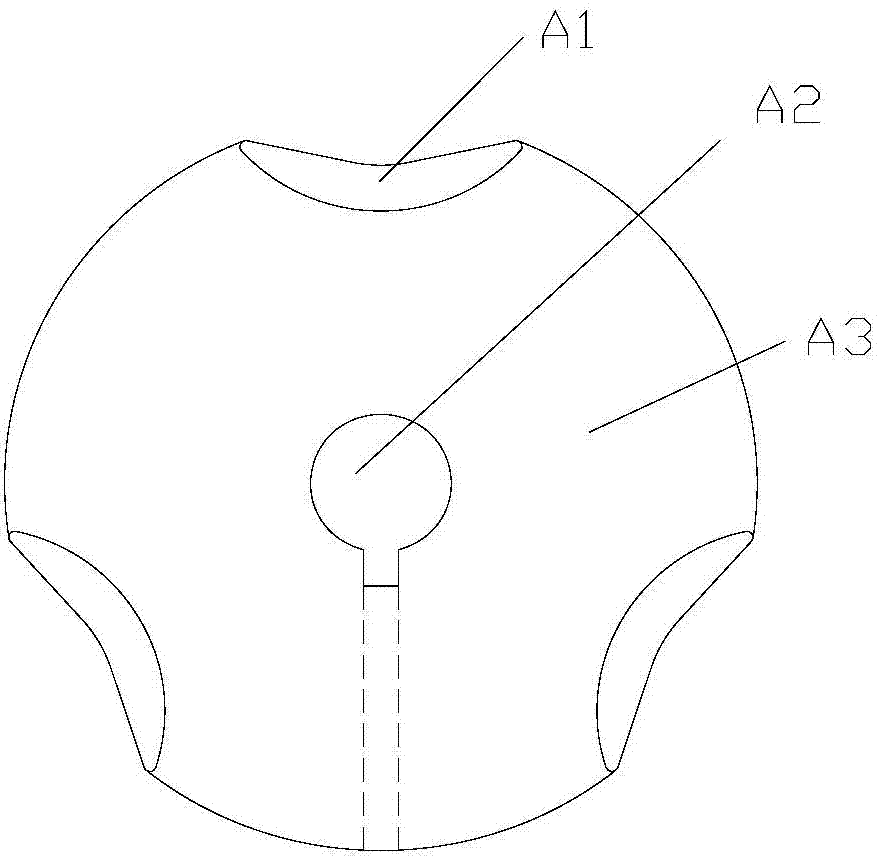

[0023] More than one sub-rotor, the sub-rotor is provided with a through hole passing through the center, all the sub-rotors are connected through the central shaft, and the central shaft passes through the through hole and is fixedly connected with the sub-rotor; The outer surface of the sub-rotor is provided with a plurality of grooves, and arcuate permanent magnets are arranged in the grooves; the central shaft is connected to the external transmission assembly as a power output shaft;

[0024] The outer cover is in the shape of a cylinder and covers the outside of the sub-rotor. Its central axis is coaxial with the central axis, and a plurality of bar magnets are evenly distributed on its inner wall. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com