PJF original number tailoring method for garment puff sleeve top model

An original number cutting method and clothing technology, applied in the direction of sewing tools, etc., can solve the problems of time-consuming, unable to meet the accuracy and speed requirements, and achieve the effect of meeting the accuracy and speed requirements and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

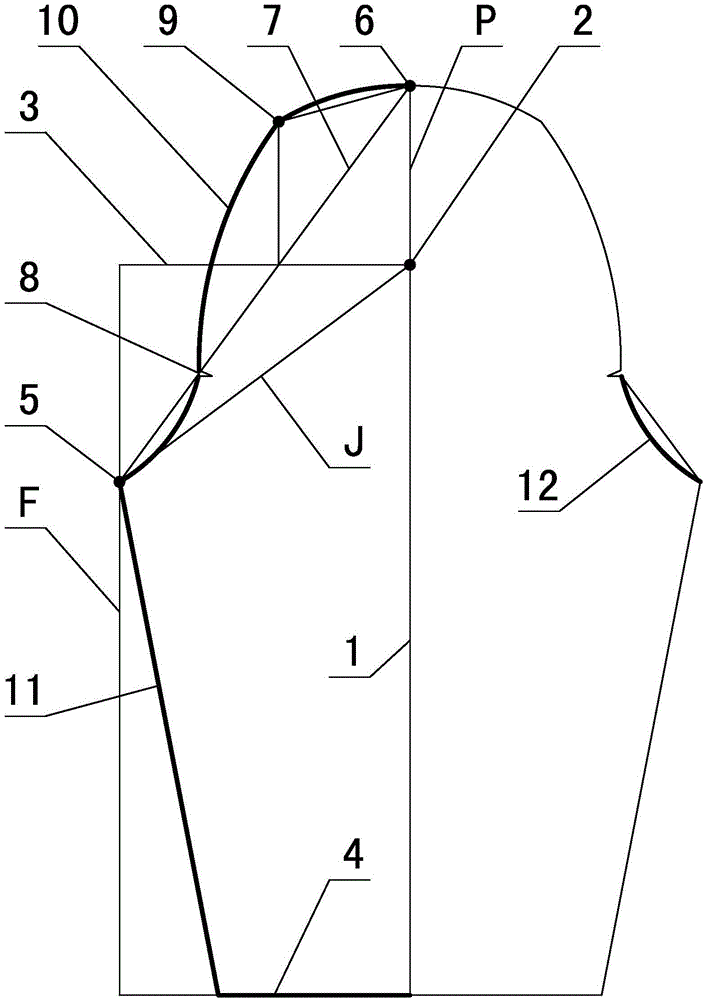

[0022] in such as figure 1 In the shown embodiment 1, a kind of PJF original number cutting method of the puff sleeve mountain modeling of clothing comprises the following steps:

[0023] a. According to the anthropometric data and the predetermined clothing style, determine the clothing original numbers of the circumference of the armhole, the length of the sleeve and the bust.

[0024] b. Determine the code name of the base of the puff sleeve mountain as P, the code name of the base line of the sleeve mountain as J, and the code name of the sleeve fat line as F, and determine that J=armhole circumference / 2.

[0025] c. Determine: bust * 0.2 = fit-fit sleeve fat width, overlap the front and rear sleeves and draw and cut, fold the material of the drawn and cut sleeves in half, determine the sleeve length line 1 on the folded line, and the high point of the sleeve mountain 2, according to the high point of the sleeve mountain Draw the sleeve fat width line 3 flatly, draw the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com