Comprehensive Calculation Method for Energy-saving Effect of Steam Turbine Seal Reformation

A technology of energy-saving effect and comprehensive calculation, applied in the field of steam turbines, can solve the problems of inability to analyze the transformation effect of steam turbine seals, and the improvement of cylinder efficiency and heat consumption rate is not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

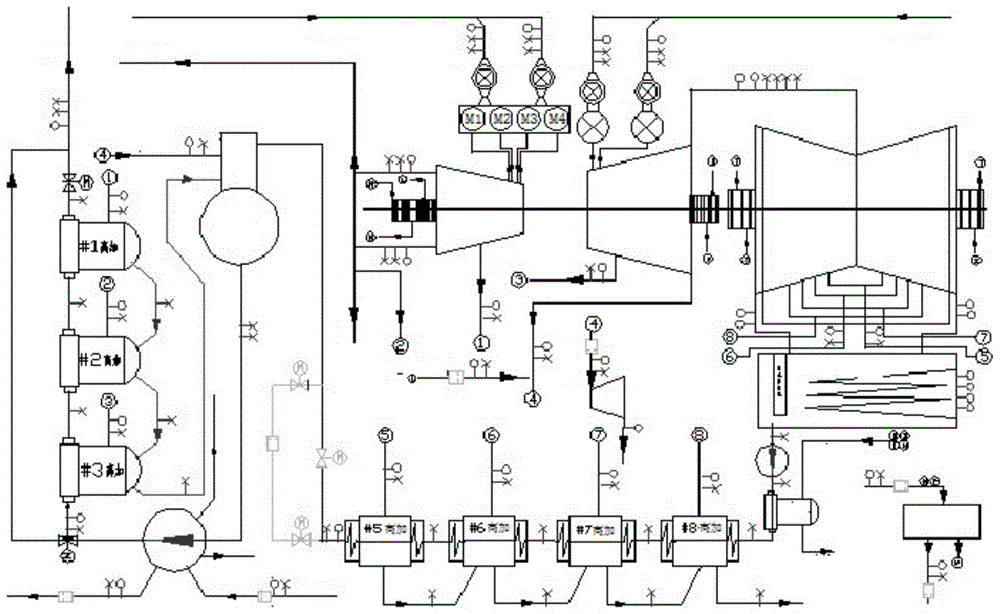

[0080] The 660MW steam turbine of a power generation company is a supercritical, single-shaft, three-cylinder (high and medium pressure combined cylinder), four-exhaust steam, one-time intermediate reheat condensing steam turbine produced by Shanghai Steam Turbine Factory. After the unit was put into production, the heat consumption rate has not reached the design value, and the heat consumption is too high. The power generation company took advantage of the opportunity of overhaul of the unit to optimize and transform the shaft end of the steam turbine and the shaft seal and steam seal of the flow part.

[0081] The reconstruction plan of steam turbine seal is as follows:

[0082] (1) The front and rear shaft seals of high and medium pressure are transformed into honeycomb type seals; (2) The low pressure shaft seals are transformed into comb teeth + contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com