Flexible continuous-body mechanical structure capable of being bent and telescopic

A mechanical structure and continuum technology, applied in the direction of manipulators, claw arms, manufacturing tools, etc., can solve problems such as large size, difficult transmission arrangement, and complicated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

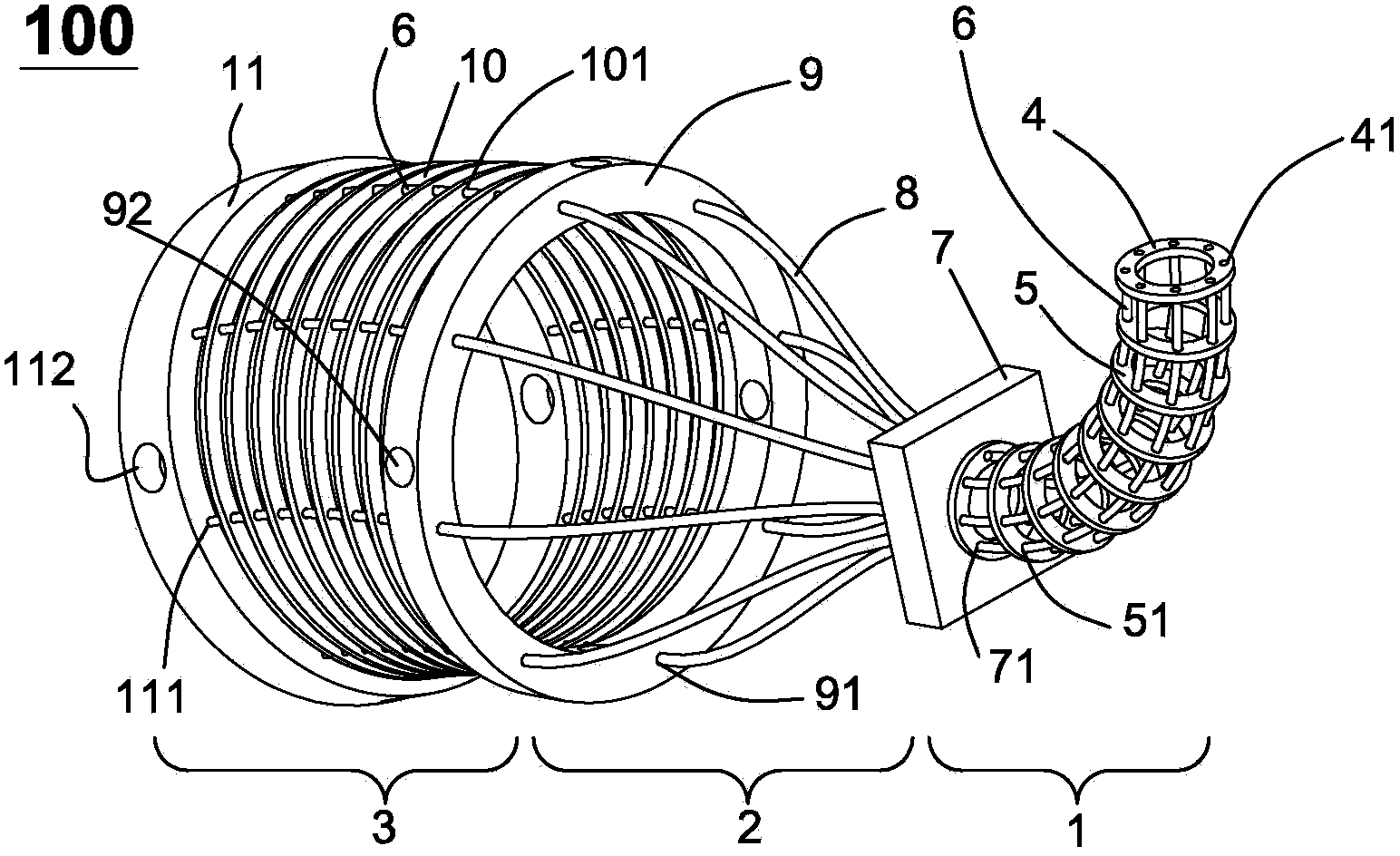

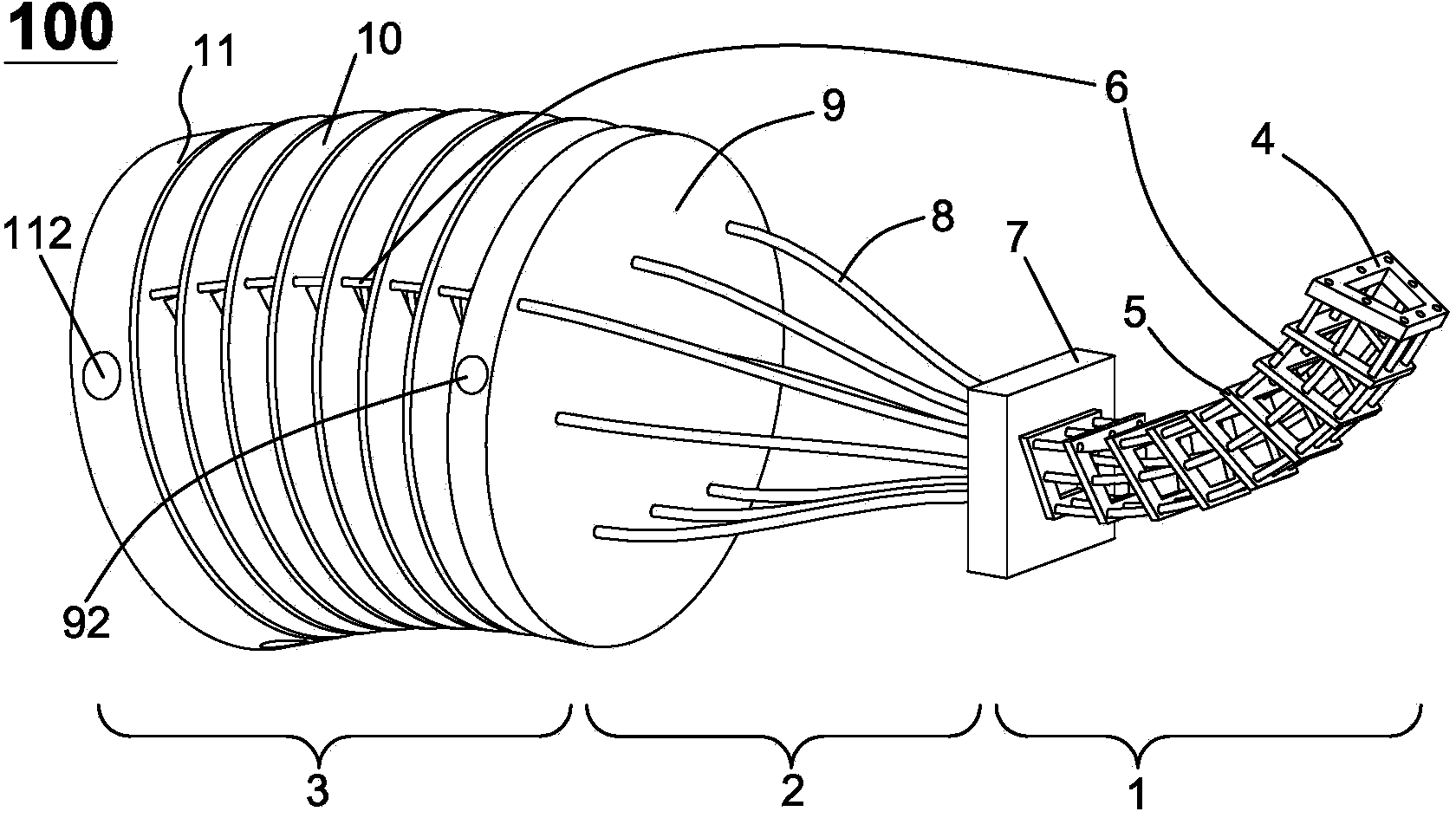

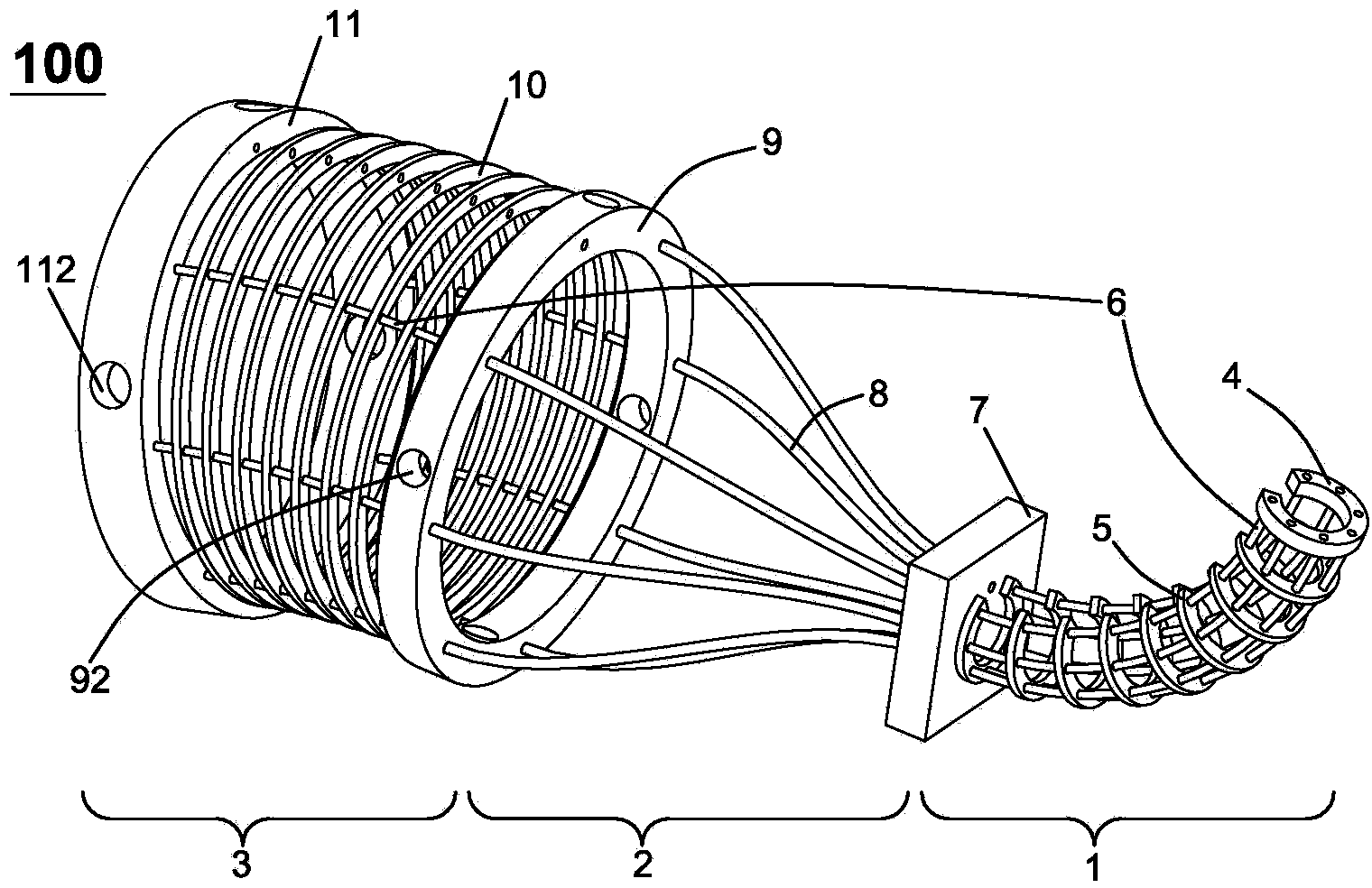

[0094] figure 1 A perspective view showing the first embodiment of the flexible continuum mechanical structure according to the present invention. Such as figure 1 , the flexible continuum mechanical structure 100 is composed of a distal structure body 1 , a middle connecting body 2 and a proximal structure body 3 . The distal structure 1 includes a distal locking disc 4, a distal spacer 5 and a structural bone 6, the middle connecting body 2 includes pipe fixing plates 7, 9 and a pipe 8, and the proximal structure 3 includes a proximal spacer 10, The proximal locking disc 11 and the structural bone 6. In this embodiment, the structural bone 6 on the distal structure 1 and the corresponding structural bone 6 on the proximal structure are the same structural bone, but those skilled in the art should understand that the structure on the distal structure 1 The bone and the corresponding structural bone 6 on the proximal structural body may also be not the same structural bone,...

Embodiment 2

[0107] Figure 10 A structural diagram showing the second embodiment of the flexible continuum mechanical structure according to the present invention. In this embodiment, the flexible continuum mechanical structure can be sequentially extended to form a multi-segment continuum mechanical structure, that is, a multi-segment proximal structure and / or a multi-segment distal structure can be sequentially extended. Figure 10 The embodiment shown in is extended with two proximal structure bodies and two distal structure bodies, which share a central connecting body. Among them, the basic structure of each proximal structure, distal structure, and middle connector figure 1 The illustrated embodiment is the same and will not be described in detail here.

[0108] Such as Figure 10 As shown, the No. 1 proximal structure 3 and the No. 1 distal structure 1 constitute the No. 1 continuum mechanical structure, while the No. 2 proximal structure 19 and the No. 2 distal structure 18 con...

Embodiment 3

[0115] Figure 15-16A structural diagram showing a third embodiment of the flexible continuum mechanical structure according to the present invention. In this embodiment, the main difference from Embodiment 2 is that a first distal kinematic chain 1a' and a second distal kinematic chain 1a' and a second distal The end kinematic chains 18a' are respectively used to enhance the rigidity, especially the torsional strength, of the No. 1 distal structure body 1' and the No. 2 distal structure body 18'. The first distal-end kinematic chain 1a' and the second distal-end kinematic chain 18a' respectively maintain compatible motion capabilities or motion compatibility with the No. 1 distal-end structure 1' and the No. 2 distal-end structure 18', thereby Can bend and stretch with it. Herein, maintaining compatible mobility or maintaining motion compatibility means that the implantation of the distal kinematic chain does not impede the movement of the distal structure, even if it local...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com