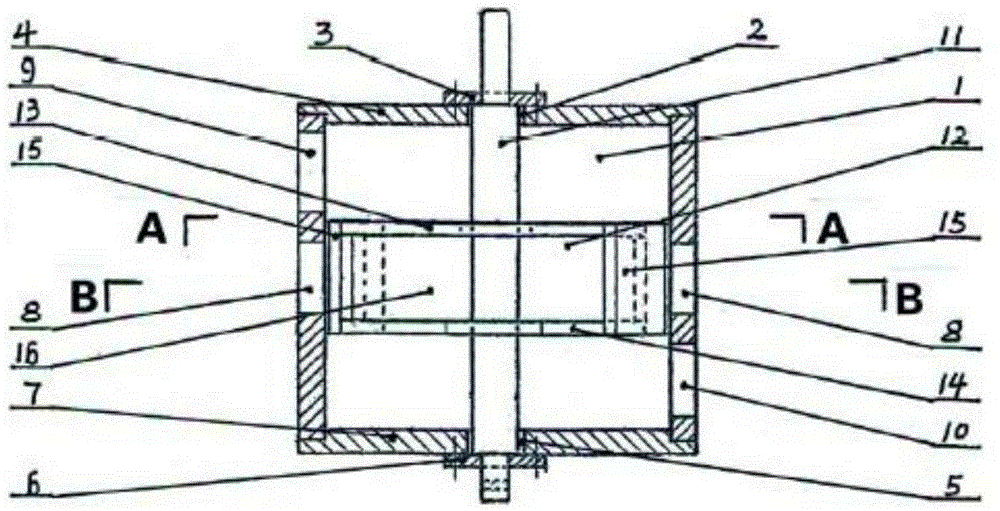

Rotary cycle switching air valve of multi-tower air dehumidifier

A technology of air dehumidification and air valve, applied in multi-way valves, valve devices, mechanical equipment, etc., can solve problems such as temperature and humidity fluctuations, large temperature and humidity fluctuations, etc., to avoid fluctuations in temperature and humidity, simple structure, and reduce wind blowing The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

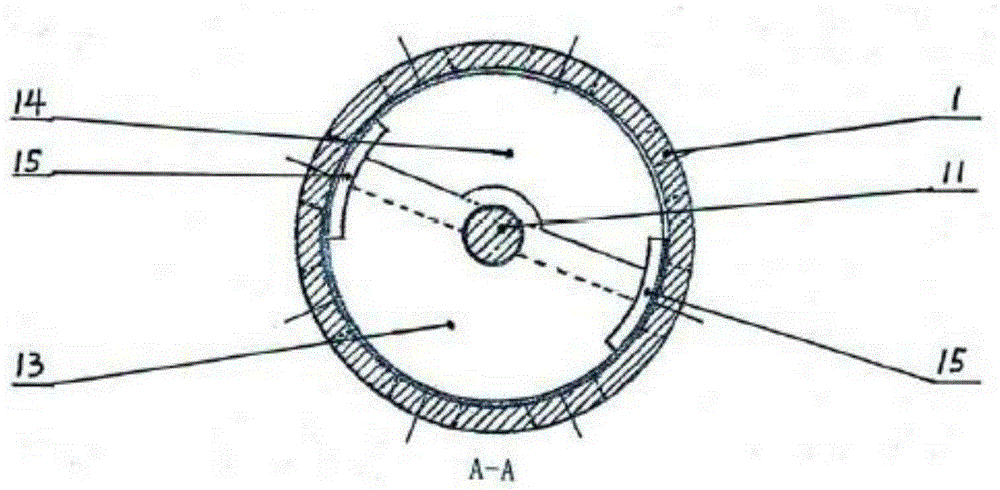

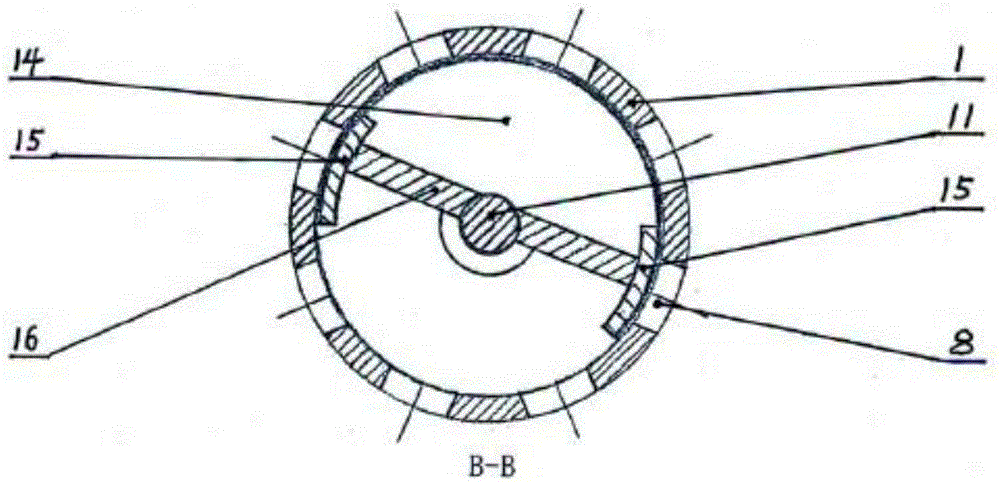

[0018] See Figures 1 to 4 The top of the cylindrical valve body 1 of the rotary cycle switching air valve of the multi-tower air dehumidifier in this embodiment is provided with an upper valve cover 4 with a central hole 2 at the center and an upper sliding bearing 3, and the bottom is provided with There is a lower valve cover 7 with a central hole 5 in the center and a lower sliding bearing 6. There are 8 identical switching air outlets 8 evenly distributed at the same height in the middle of the valve body 1. An upper air outlet 9 is provided on one side of the upper part. The other side of the lower part is provided with a lower tuyere 10; the valve stem 11 is installed in the cavity of the valve body 1 to pass through the upper sliding bearing 3 and the lower sliding bearing 6. place; one side of the upper part of the valve core 12 is provided with a flat semi-circular or fan-shaped (semi-circular in this embodiment) upper valve plate 13, and the other side of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com