Assembly method of technical mound layer and panel

An assembly method and a technology of lamination, applied in the direction of door leaf, etc., can solve problems such as hidden quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

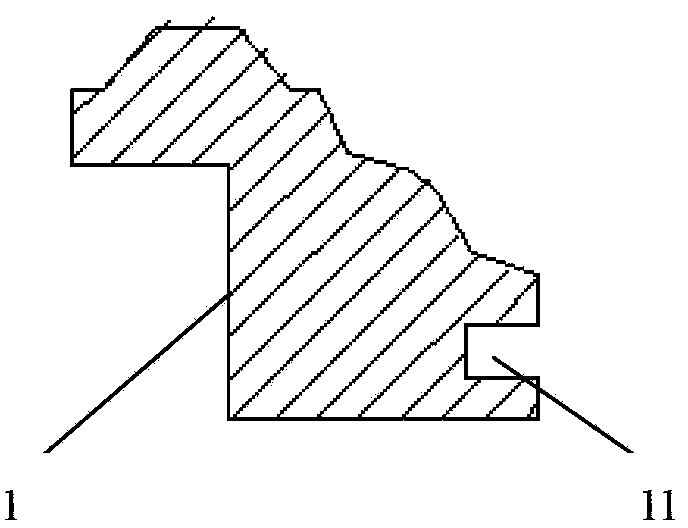

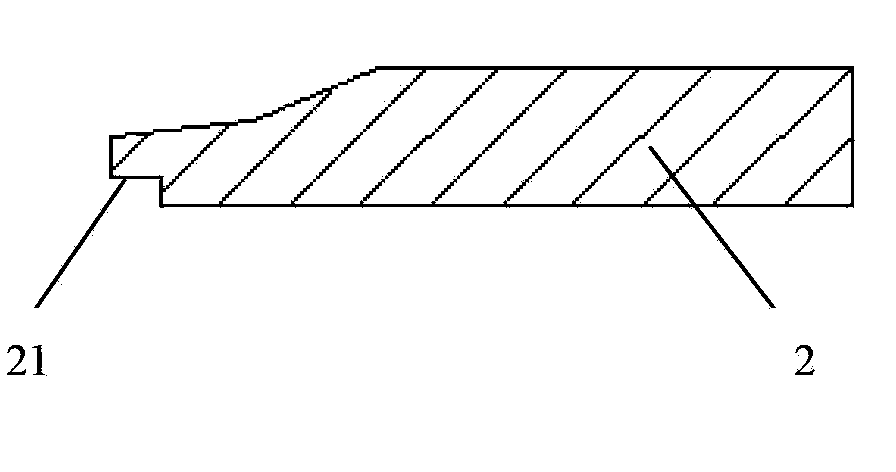

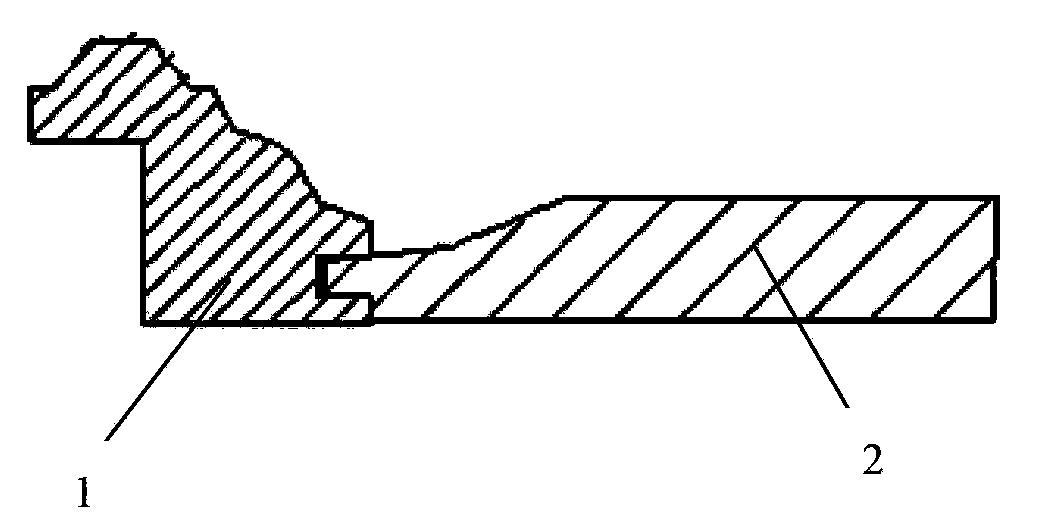

[0017] see Figure 1 to Figure 3 , a method of assembling process bead and pool plate of the present invention, it comprises the steps:

[0018] 1) Grooving 11 of process bead 1: use a vertical shaft machine equipped with a saw blade to open a 3mm×3.5mm groove 11 on process bead 1;

[0019] 2) Grooving 21 of the pool plate 2: using a vertical shaft machine equipped with a saw blade to open a 3mm×3mm groove 21 on the shaped pool plate 2;

[0020] 3) Put glue in groove 11 of process bead 1;

[0021] 4) Through the cooperation of the upper groove 11 of the process bead 1 and the groove 21 of the pool plate 2, manually combine the process bead 1 and the pool plate 2 into a whole;

[0022] 5) Drive a 30mm straight nail into the bottom of the process bead 1, and fix the process bead 1 with the pool plate 2.

[0023] The glue is two-component puzzle glue.

[0024] Both the process bead 1 and the pool plate 2 are made of high-density board material.

[0025] In summary, the conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com