Anti-vibration device

A technology for anti-vibration devices and components, applied in the direction of non-rotational vibration suppression, springs made of plastic materials, springs, etc., can solve problems such as increasing the spring constant, and achieve the effect of increasing the spring constant and reducing the spring constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

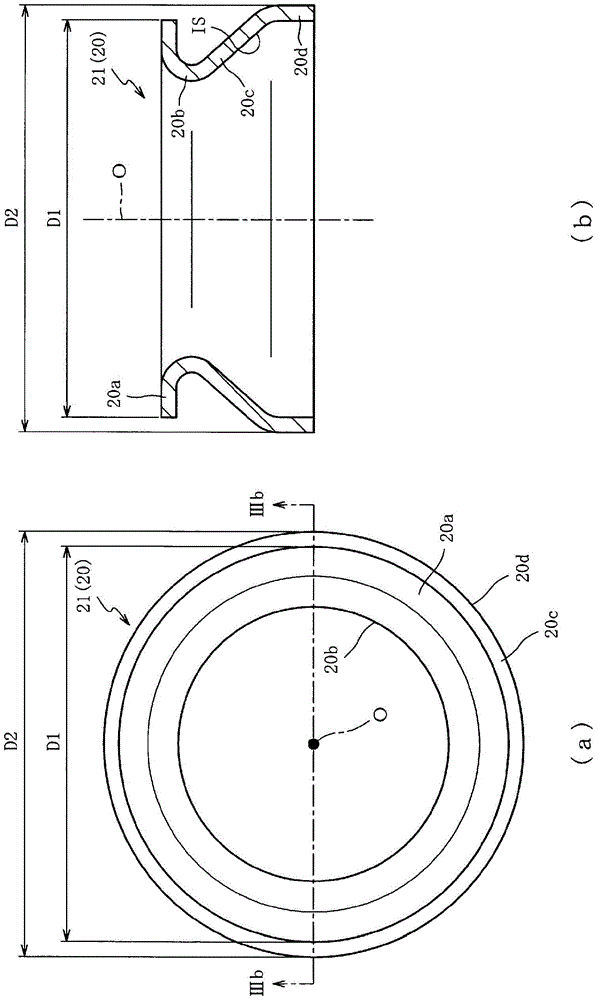

[0140] refer to Figure 14 and Figure 15 , the method of assembling the anti-vibration device 400 assembled from the vulcanized molded body D and the cylindrical member 440 will be described. In the first embodiment (anti-vibration device 100), by rubber matrix compression process (cf. Figure 7 ) to compress the rubber base 30 (the first rubber part 31 and the second rubber part 32 ) in the direction of the axis O, but the rubber base compression process is omitted in the fourth embodiment (the anti-vibration device 400 ).

[0141] Figure 14 (a) is a cross-sectional view of the vulcanized molded body D in a state before drawing in the outer cylinder drawing process; Figure 14 (b) is a cross-sectional view of the vulcanized molded body D in a state where drawing has been performed in the outer cylinder drawing process.

[0142] Such as Figure 14 As shown, for the vulcanized molded body D, in the outer cylinder drawing process, the diameters of the first outer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com