Improved electric stapler

A stapler and electric technology, which is applied in the mechanical field, can solve the problems of inconvenience and inability of the stapler to work, and achieve the effect of reducing the number of staples and making it easy to take out paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

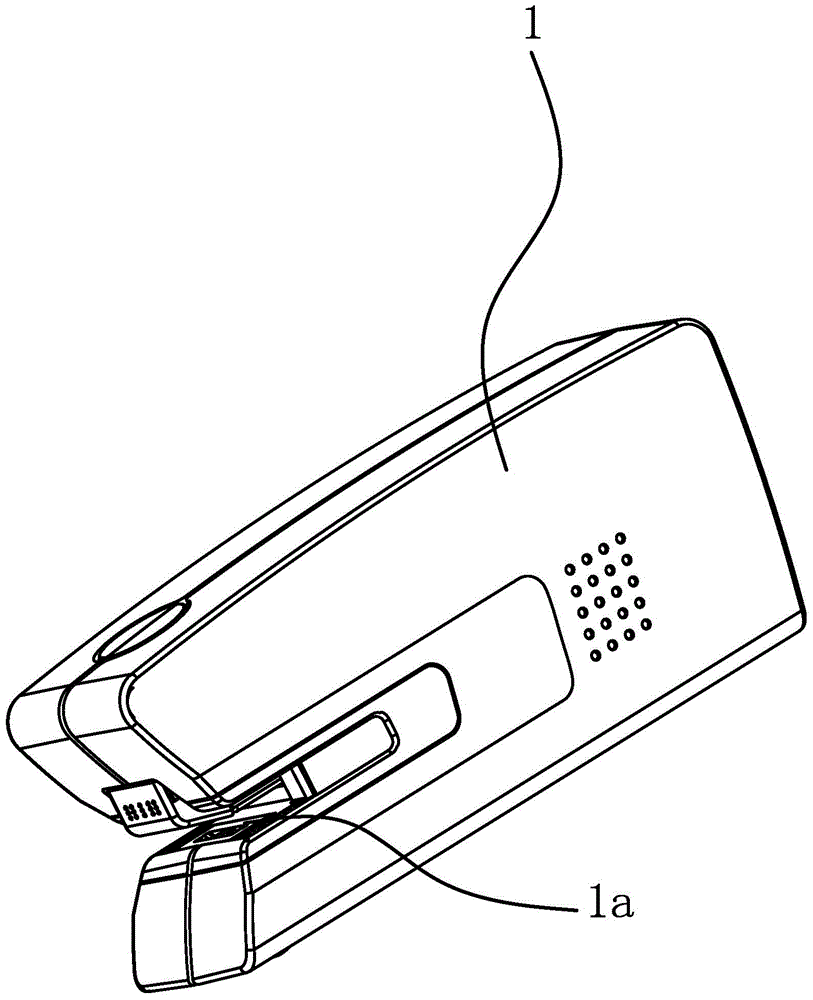

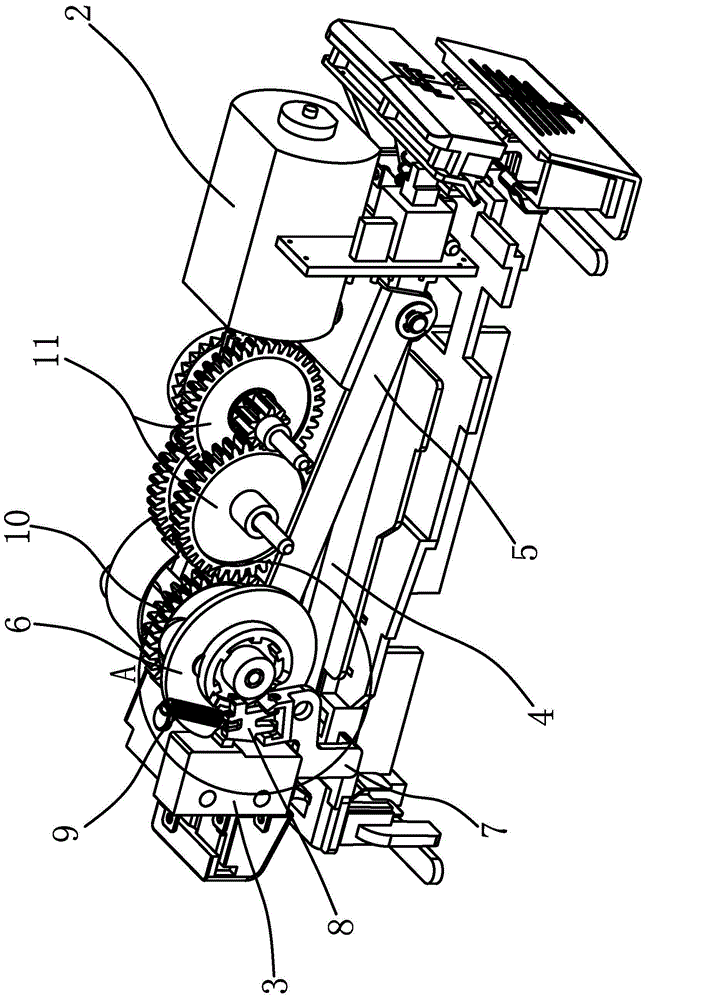

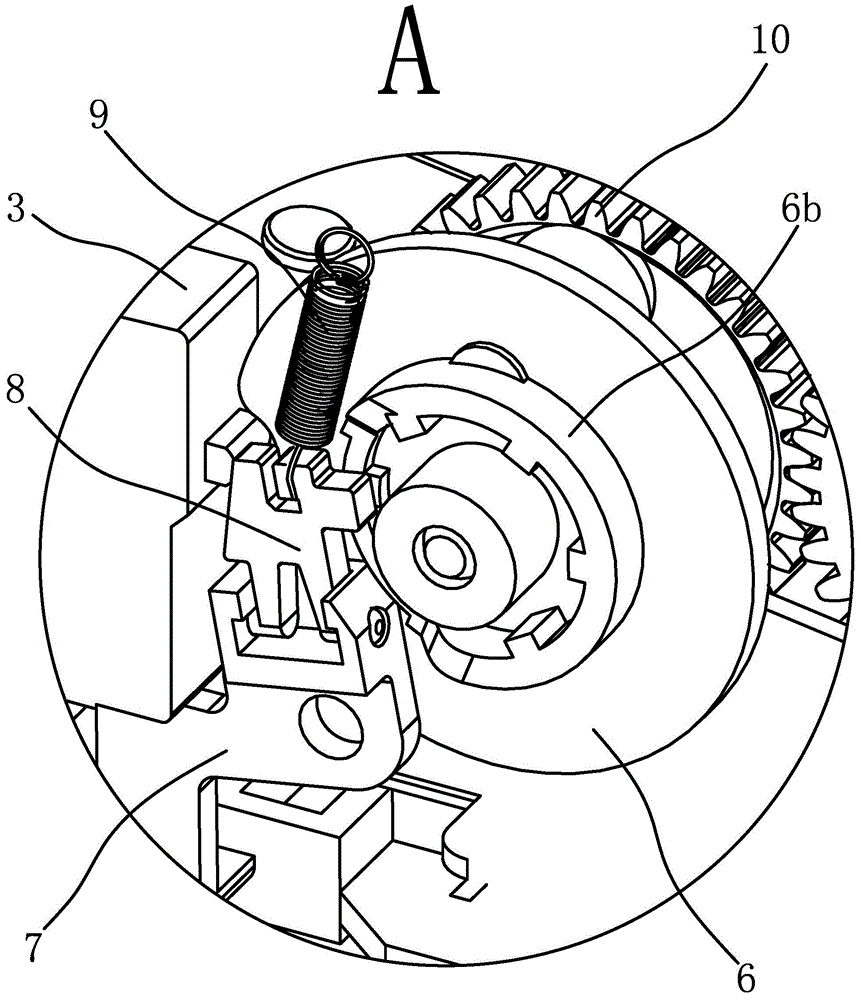

[0033] like figure 1 and figure 2 and image 3 As shown in the figure, the improved electric stapler includes a casing 1 with a cavity inside, the front end of the casing 1 is provided with a paper opening 1a, and the casing 1 is provided with a motor 2, a micro switch 3, a nail path 4 and a knife Frame 5, a drive gear 10 and a runner 6 driven by the drive gear 10 are arranged between the motor 2 and the micro switch 3. The outer edge of the runner 6 has a notch 6a, and a switch 7 is hinged on the inner wall of the housing 1. The switch The upper end of 7 is hinged with a paddle 8, one side of paddle 8 is in contact with the button of micro switch 3, a spring 9 is connected between paddle 8 and the inner wall of housing 1, and the wheel 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com