Jointless bridge based on arc structure arranged behind bridge abutment and construction method thereof

A technology of arched structure and construction method, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of not fundamentally solving the problem of bridge stretching joints, the expansion joints of slotted bridges are easily damaged, and achieve the solution of bridge head Car jumping problem, reducing post-maintenance, improving the effect of common damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

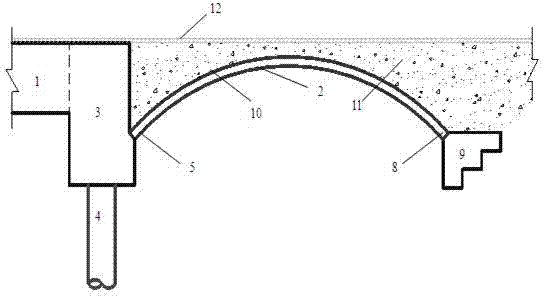

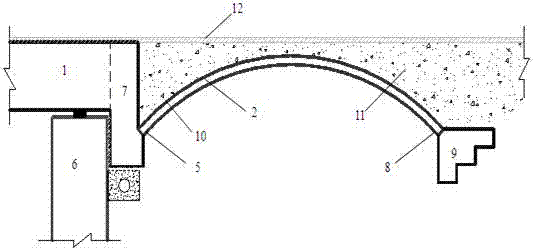

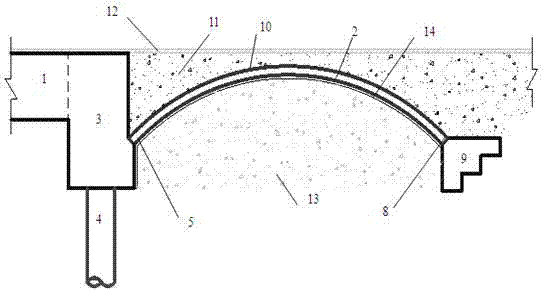

[0034] The present invention is based on a bridge without expansion joints with an arched structure behind the platform, such as figure 1 As shown, including the span structure 1 and the abutment, an arch structure 2 is arranged behind the abutment, and the displacement from the span structure 1 is absorbed by the deformation of the arch structure 2 .

[0035] If the abutment is an integral abutment, the bridge span structure and the integral abutment body 3 are consolidated, the abutment foundation should be a single-row pile foundation 4, and the arch structure 2 is near the bridge end arch foot 5 and the abutment. If it is a semi-integral abutment, the bridge span structure 1 is supported on the semi-integral abutment body 6 through supports, and an end beam 7 is provided at the end of the bridge structure 1 to resist the earth pressure behind the abutment function, the arched structure 2 is connected to the end beam 7 near the bridge span end arch foot 5 . The arched stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com