Low power consumption constant current and backlight control circuit and TV

A technology of backlight control and linear constant current circuit, which is applied in the field of televisions and can solve problems such as high power consumption, increased cost, and reduced circuit efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

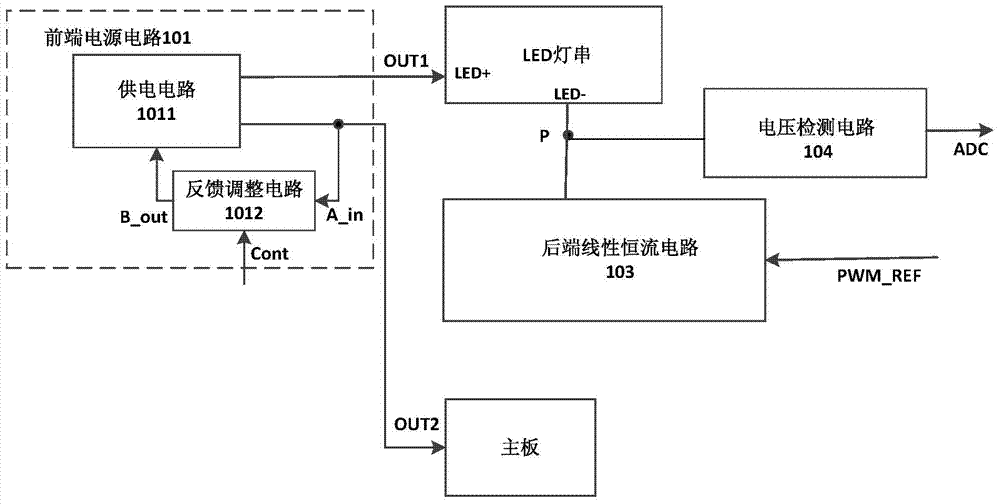

[0082] see figure 2, is a structural schematic diagram of an embodiment of the low power consumption constant current and backlight control circuit provided by the present invention.

[0083] In this embodiment, the low power consumption constant current and backlight control circuit includes a front-end power supply circuit 101 , a back-end linear constant current circuit 103 and a voltage detection circuit 104 .

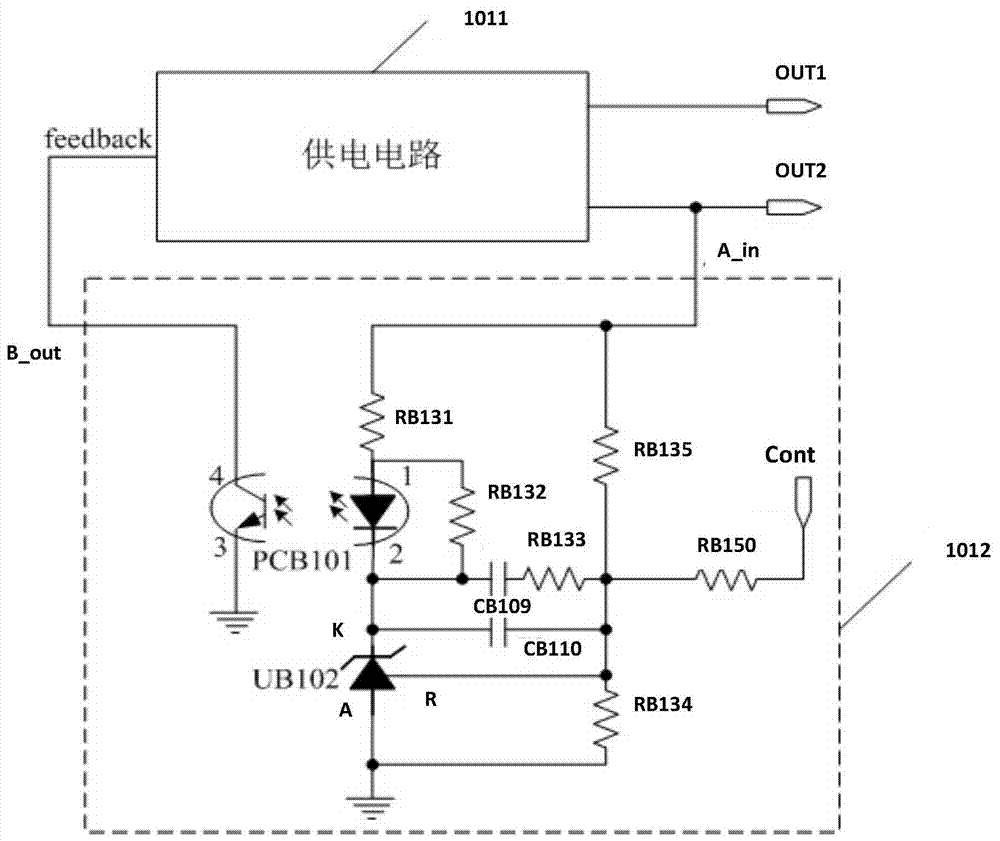

[0084] The front-end power supply circuit 101 includes a power supply circuit 1011, a first power supply output terminal OUT1, a second power supply output terminal OUT2 and a feedback adjustment circuit 1012;

[0085] Wherein, the feedback adjustment circuit 1012 includes a feedback input terminal A_in, a control signal input terminal Cont and a feedback signal output terminal B_out; the feedback input terminal A_in is connected to the second power supply output terminal OUT2, and the feedback signal output terminal B_out Connected to the power supply circuit 10...

Embodiment 2

[0129] refer to Figure 7 , is a schematic structural diagram of the second embodiment of the low power consumption constant current and backlight control circuit provided by the present invention.

[0130] In this embodiment, on the basis of Embodiment 1, further, the low power consumption constant current and backlight control circuit provided in this embodiment further includes a control main chip 105 . Among them, the basic structure and working principle of the front-end power supply circuit 101 , the back-end linear constant current circuit 103 and the voltage detection circuit 104 are the same as those of the above-mentioned embodiments, and will not be repeated here.

[0131] The control main chip 105 is respectively connected to the control signal input terminal Cont, the reference signal input terminal PWM_REF and the voltage acquisition output terminal ADC;

[0132] The control main chip 105 adjusts the magnitude of the signal output to the control signal input ter...

Embodiment 3

[0136] refer to Figure 8 , is a schematic structural diagram of the third embodiment of the low power consumption constant current and backlight control circuit provided by the present invention.

[0137] Like Embodiment 1, the low power consumption constant current and backlight control circuit of this embodiment includes a front-end power supply circuit 101 , a rear-end linear constant current circuit 103 and a voltage detection circuit 104 . Wherein, the shown front-end power supply circuit 101 and back-end linear constant current circuit 103 are consistent with the structure and working principle of Embodiment 1, and the description is omitted here. Different from Embodiment 1, the voltage detection circuit 104 of this embodiment includes a diode DB2 and a pull-up resistor RB18, the cathode of the diode DB2 is connected to the cathode LED- of the LED light string, and the anode of the diode DB2 is connected to the upper One end of the pull-up resistor RB18 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com