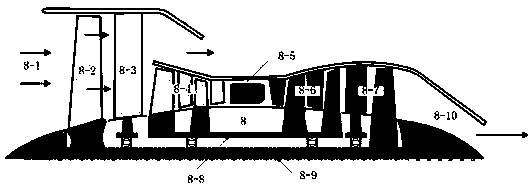

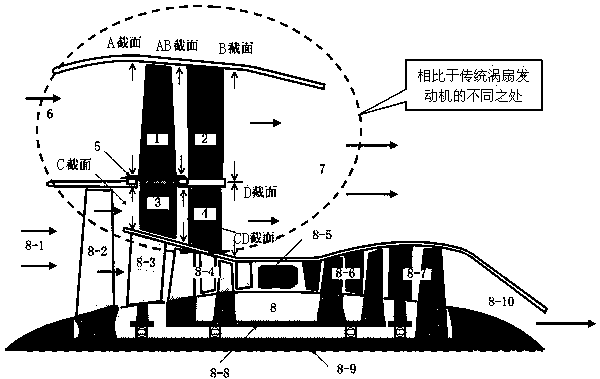

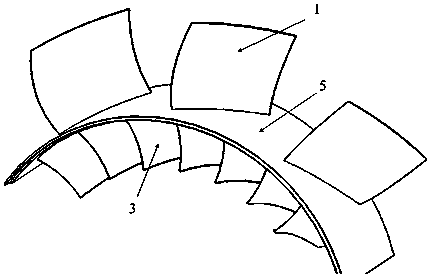

Self-propelled fan high bypass ratio turbofan engine with inner ring air turbine

A turbofan engine, air turbine technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of inability to contribute to the economy, difficult to manufacture fans and turbines, complex rotor dynamics, etc. Risk and development cost, the effect of solving the speed mismatch problem and avoiding the rotor dynamics problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] For a dual-rotor turbofan engine, its total flow is 95.3kg / s, the internal total pressure ratio is 23, the outer culvert total pressure ratio is 1.7, the bypass ratio is 5.3, the maximum thrust is 2546.6dN, and the corresponding fuel consumption rate is 1.05kg / (dN *h). After remodeling and designing according to the method proposed by the present invention, the total pressure ratio of the outer culvert is 1.2 and the bypass ratio is 14.3. Through the overall performance calculation, the maximum thrust is 3703.1dN, corresponding to the fuel consumption rate of 0.72kg / (dN*h), and the thrust is higher than the prototype The turbofan engine has increased by 45.4%, fuel consumption has been reduced by 31.4%, and its performance has been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com