Straight stroke mechanism of multi-turn electric actuator

An electric actuator and straight-stroke technology, which is applied in the improved invention field of the straight-stroke mechanism, can solve problems such as potential safety hazards, damaged valves, losses, etc., and achieves the effect of eliminating hidden dangers of damage, simple structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

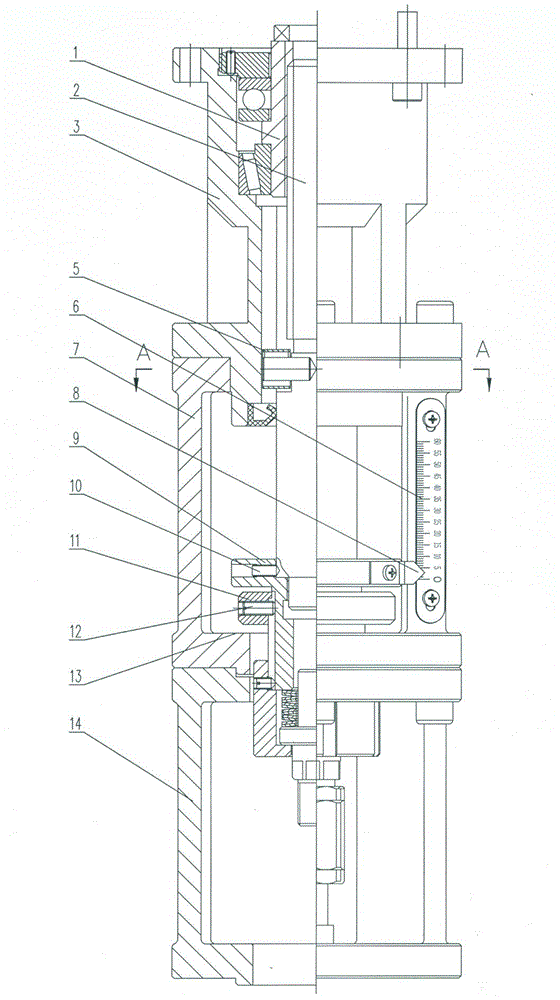

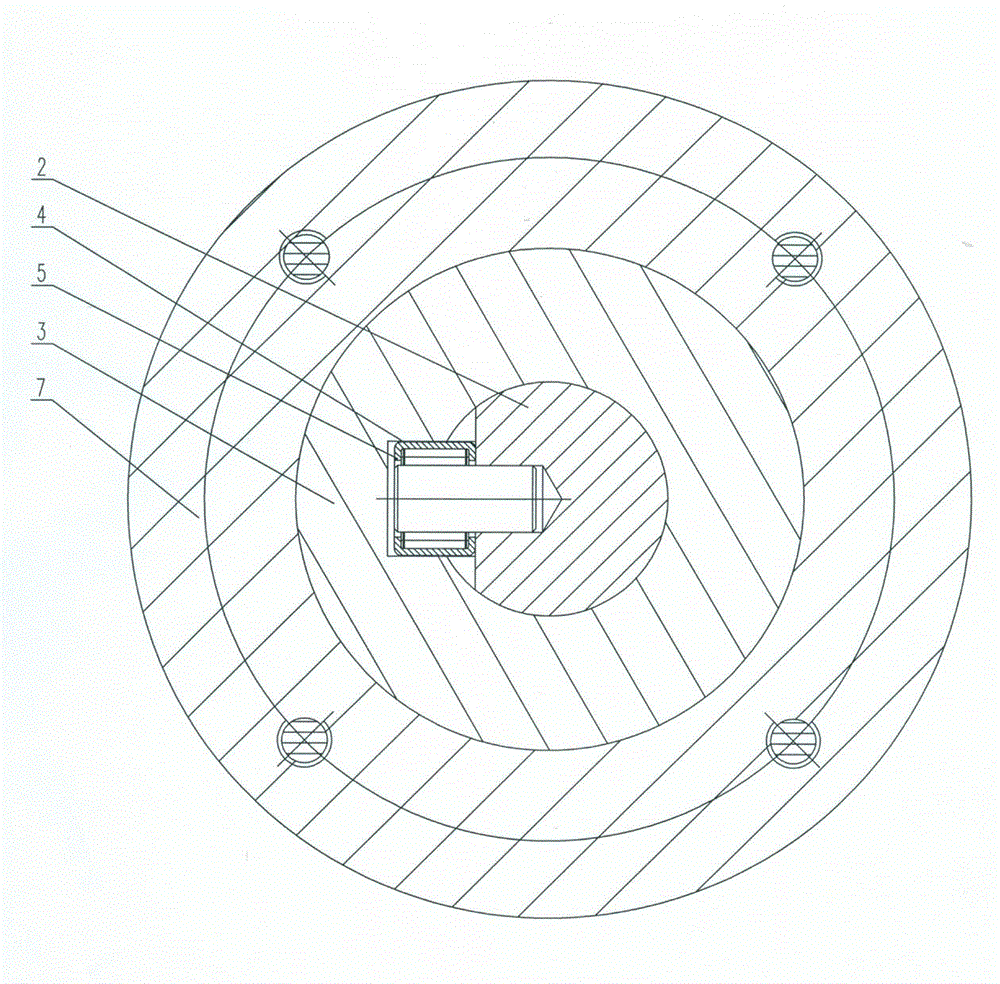

[0013] Referring to the accompanying drawings, the linear travel mechanism of this kind of multi-rotation electric actuator includes a bracket 7, a bearing seat 3, a screw rod 2 and a nut 1 matched with the screw rod, and the bearing seat 3 is installed on the bracket 7. The present invention can According to the length of the valve stem, a flange bracket 14 can be added under the bracket 7. When the valve stem is short, the screw rod 2 can be lengthened. Otherwise, a shorter screw rod can be used, so that it can be applied to more types of valves, and the processing is convenient and fast. Low cost; the nut 1 is connected to the main shaft of the multi-turn electric actuator, the screw 2 is vertically arranged in the bearing seat 3, and the inner surface of the bearing seat 3 is provided with a vertically arranged guide groove 4, the The screw 2 corresponding to the guide groove 4 is equipped with a matching needle bearing 5, the needle bearing 5 is placed in the guide groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com