Patents

Literature

60results about How to "Eliminate the risk of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

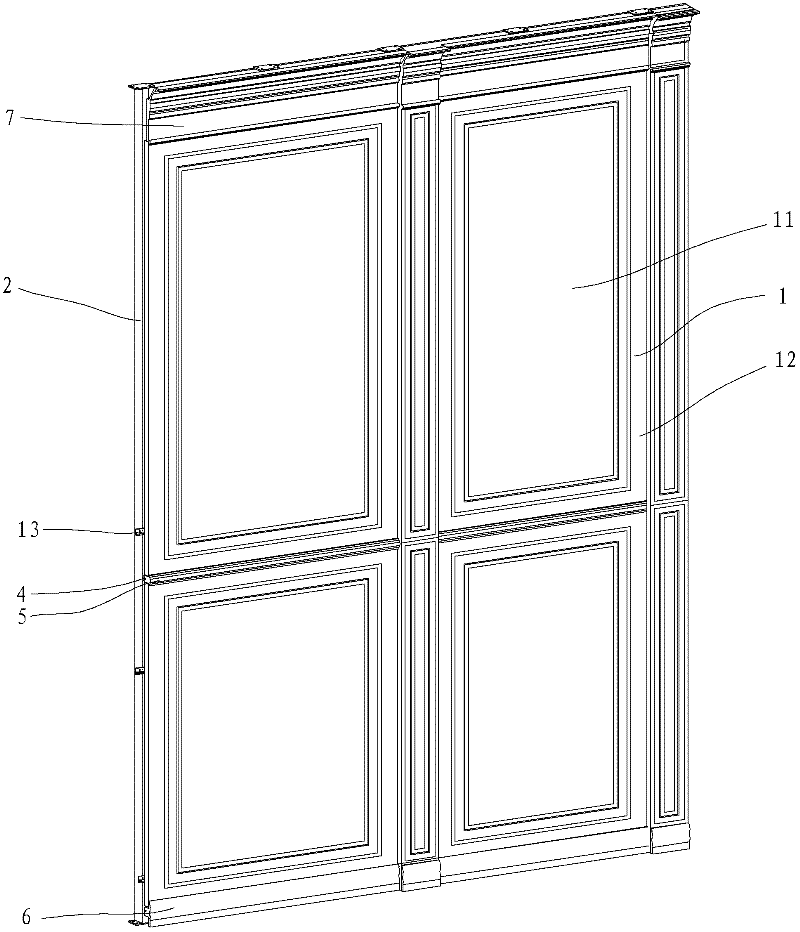

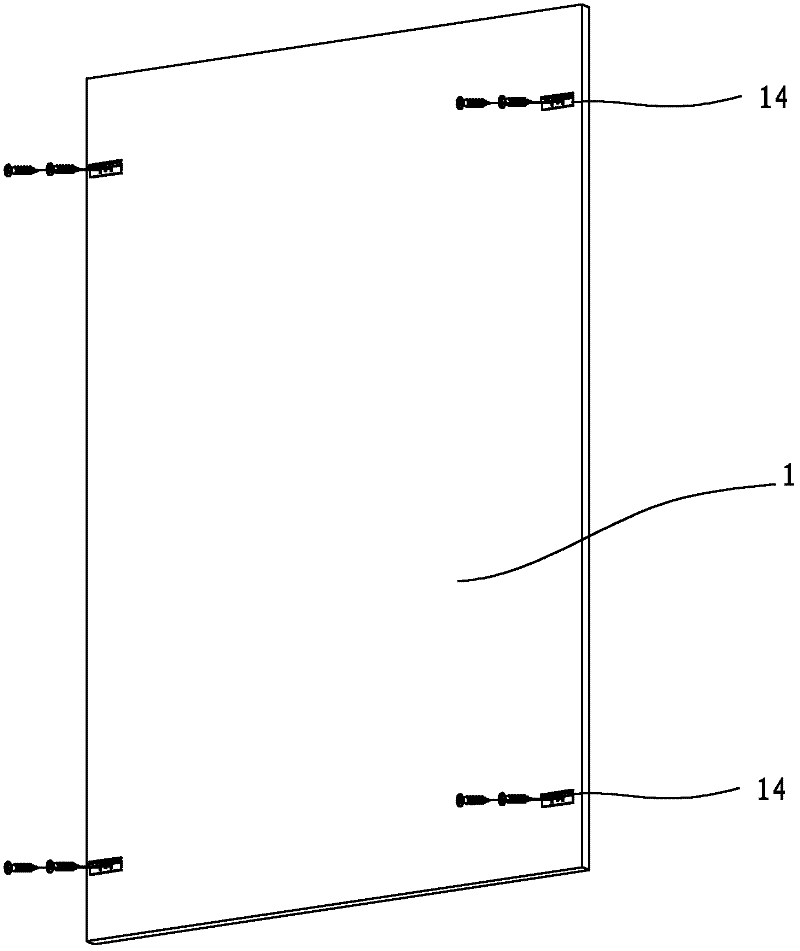

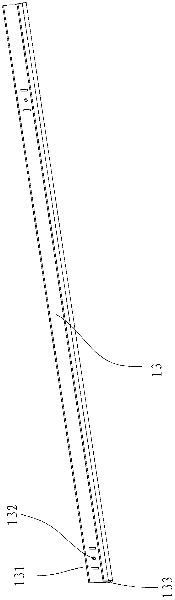

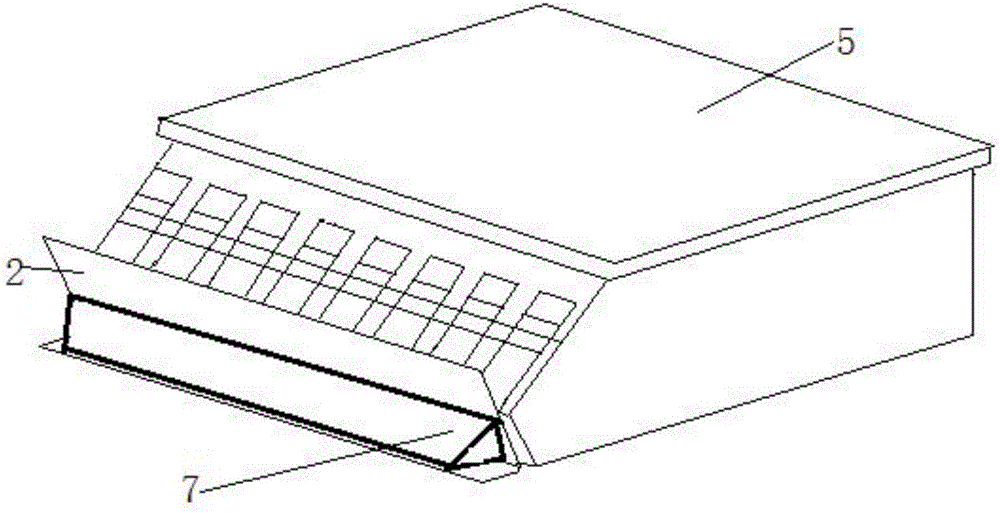

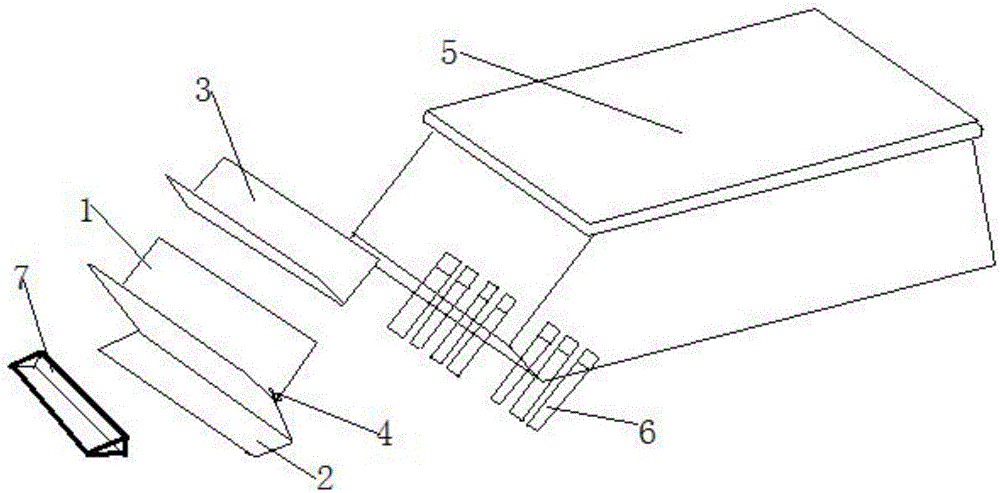

Revetment and mounting method thereof

The invention discloses a revetment. The revetment comprises a plurality of detachable revetment plates and is characterized by further comprising a plurality of mutually parallel vertical columns, wherein the vertical columns are arranged in a same plane, are fixed on the ground and are vertical to the ground, adsorption layers are paved among the vertical columns, and the revetment plates are detachably fixed on the vertical columns. The revetment disclosed by the invention has a detachable mounting structure, thus the verticality of the revetment can be ensured, the manufacturing and mounting of the revetment plates are simplified by virtue of horizontal regulation of the detachable mounting structure, and the moisture on a wall can be adsorbed so that the revetment plates are protected and the service lives of the revetment plates are prolonged. Furthermore, the invention further discloses a mounting method of the revetment.

Owner:应孝华

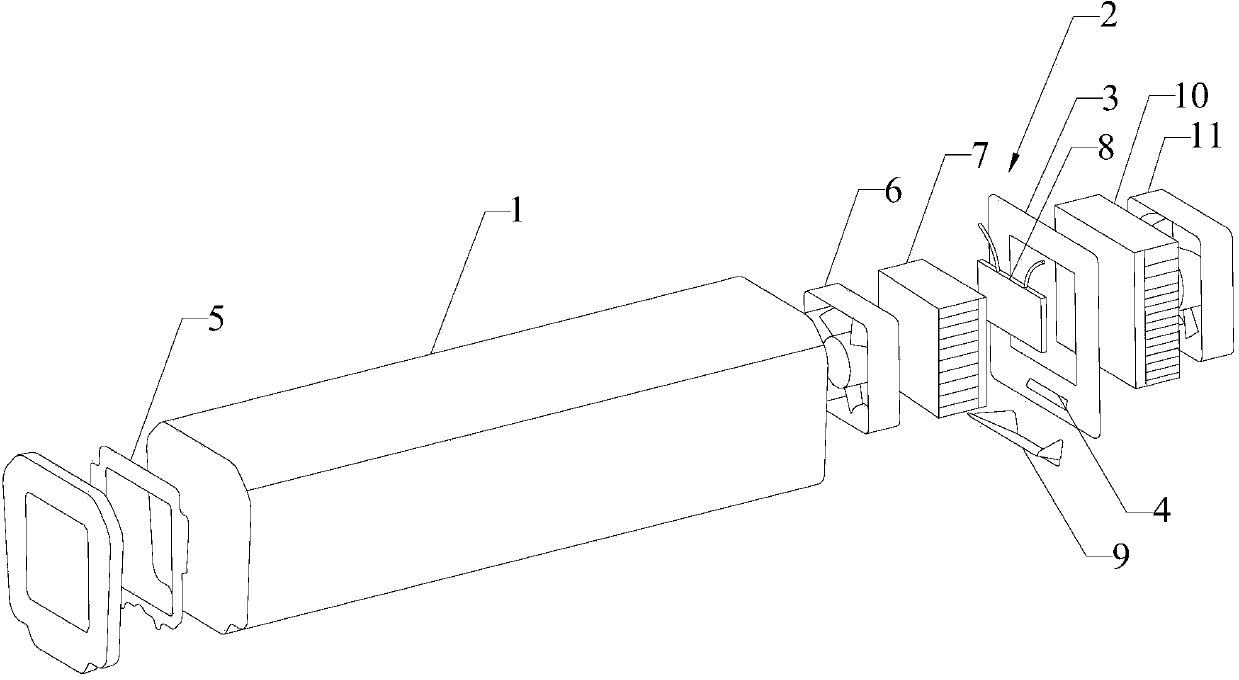

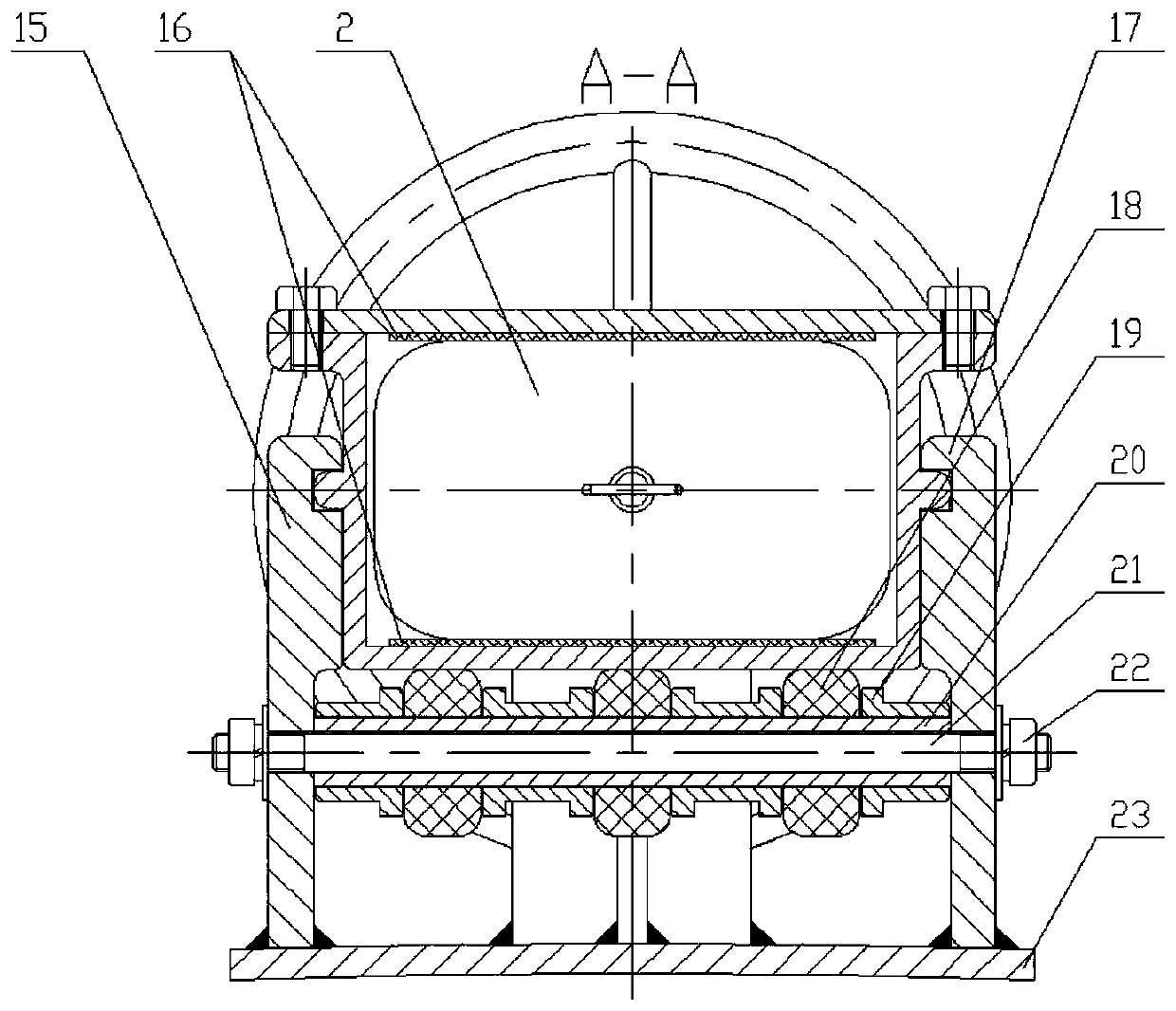

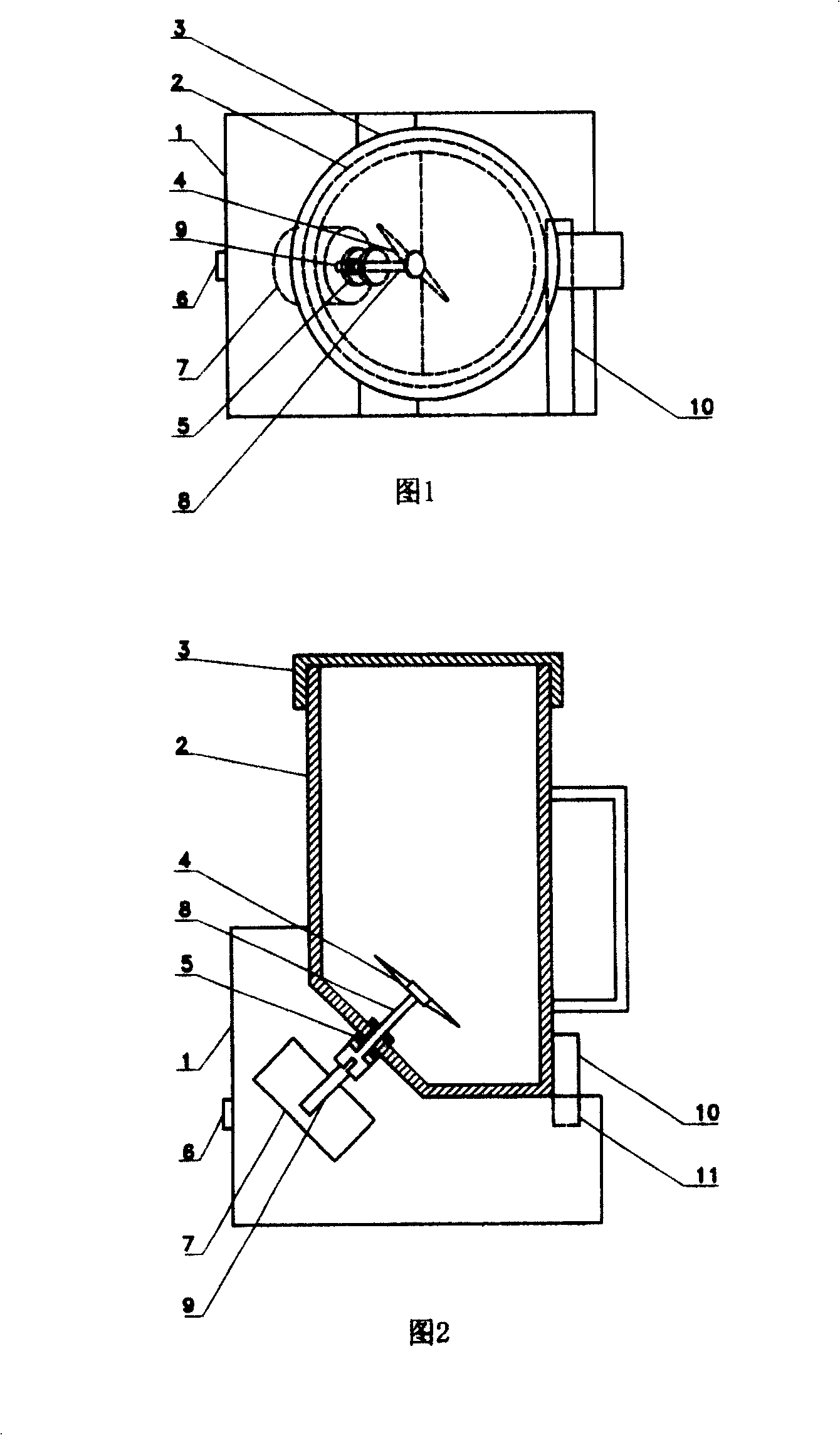

Monitoring pick-up device and cooling and dehumidifying method thereof

InactiveCN104219433AImprove working conditionIncrease humidityTelevision system detailsColor television detailsEngineeringSemiconductor

The invention provides a monitoring pick-up device and a cooling and dehumidifying method thereof. The device comprises a monitoring camera protection frame and a cooling and dehumidifying device; a water guide hole is formed in the bottom of the rear cover of the protection frame; the control panel of the cooling and dehumidifying device is fixedly arranged on the protection frame; the rear cover is provided with a hollow part in which a semiconductor chilling plate is corresponding arranged; a first radiator is fixedly connected to one side, facing the protection frame, of the semiconductor chilling plate; a first fan is fixedly connected with the first radiator; a second radiator is fixedly connected to the outer side of the semiconductor chilling plate; a second fan is fixedly connected with the second radiator; a water receiving tank is arranged on the inner side of the rear cover and located under the water guide hole; a water absorbing material is paved in and at the periphery of the water guide hole. The monitoring pick-up device has the advantages of high cooling and dehumidification effect, and low operation noise, and can be protected against the influence of environmental factors and operates well.

Owner:SHENZHEN INFINOVA

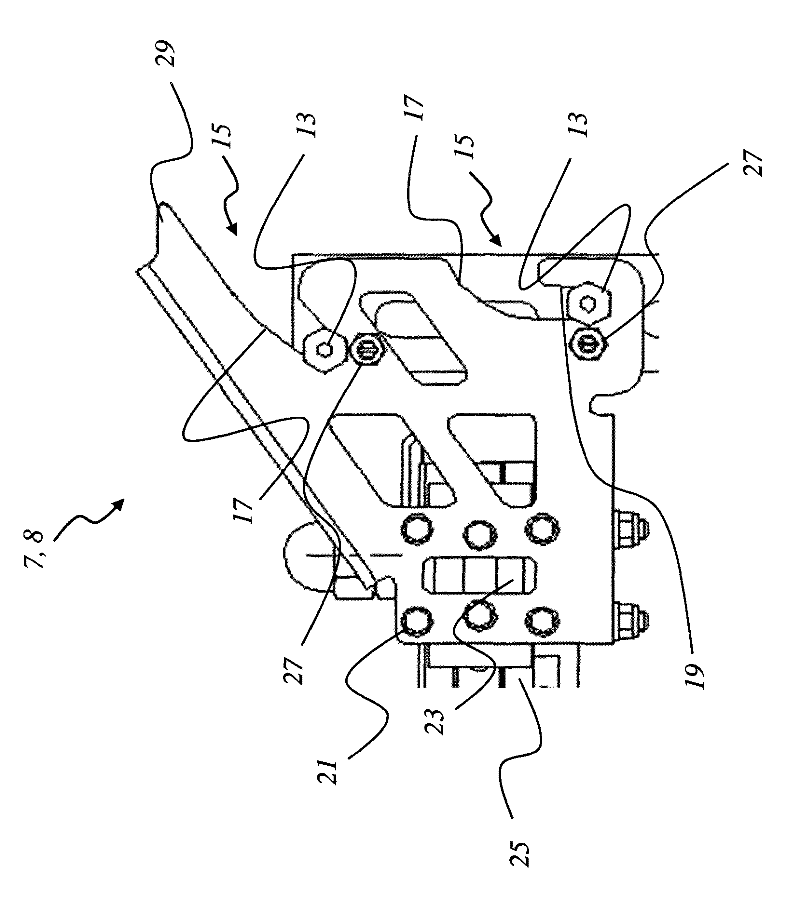

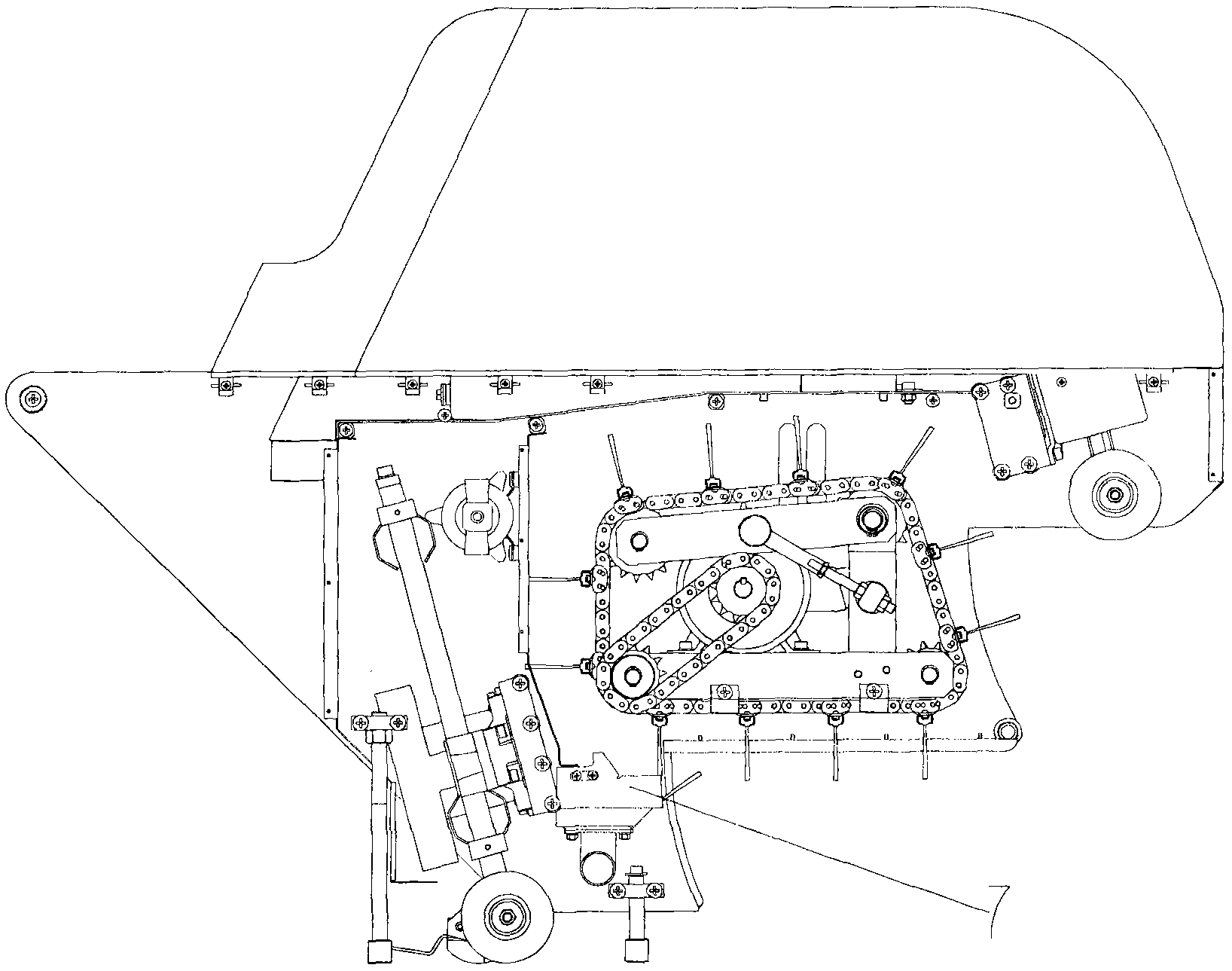

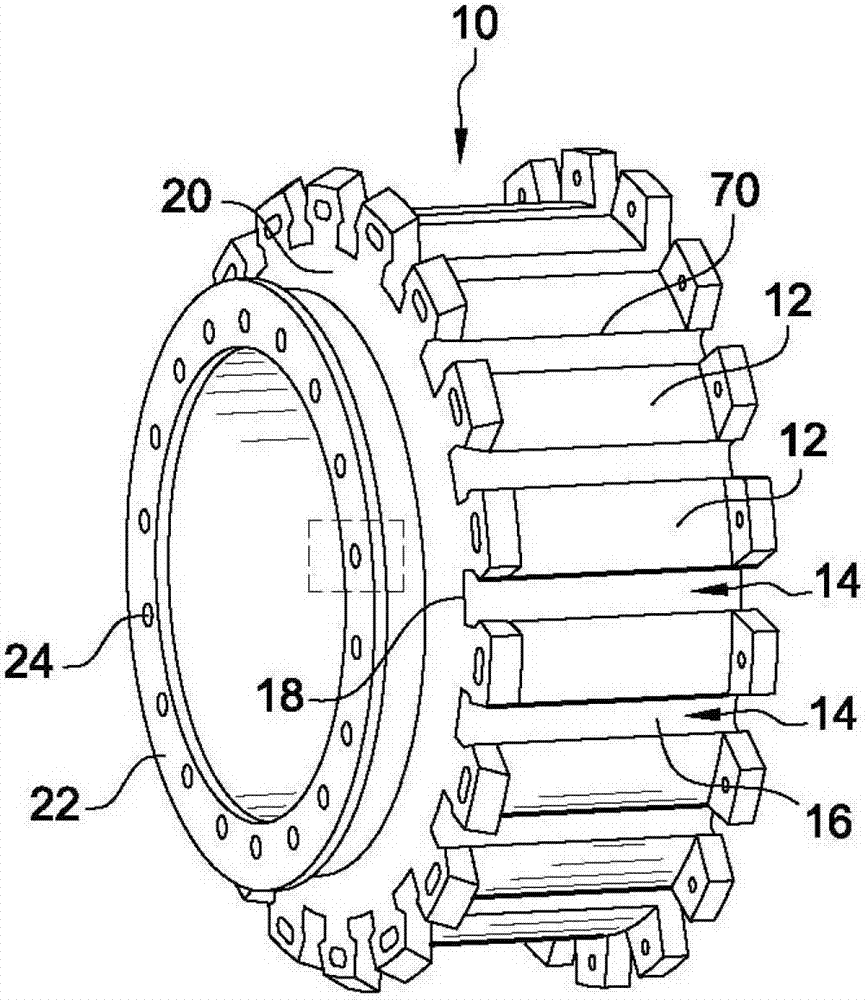

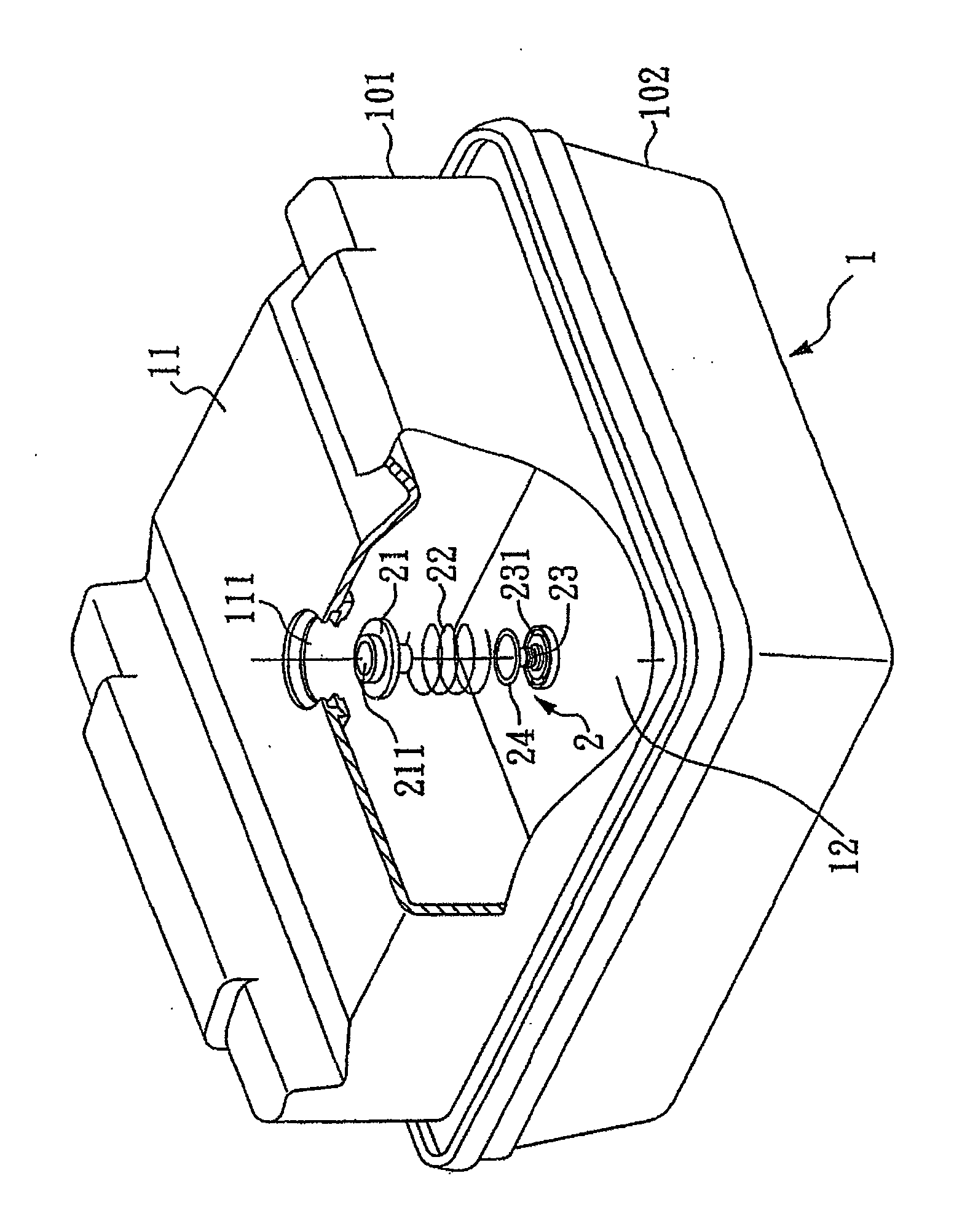

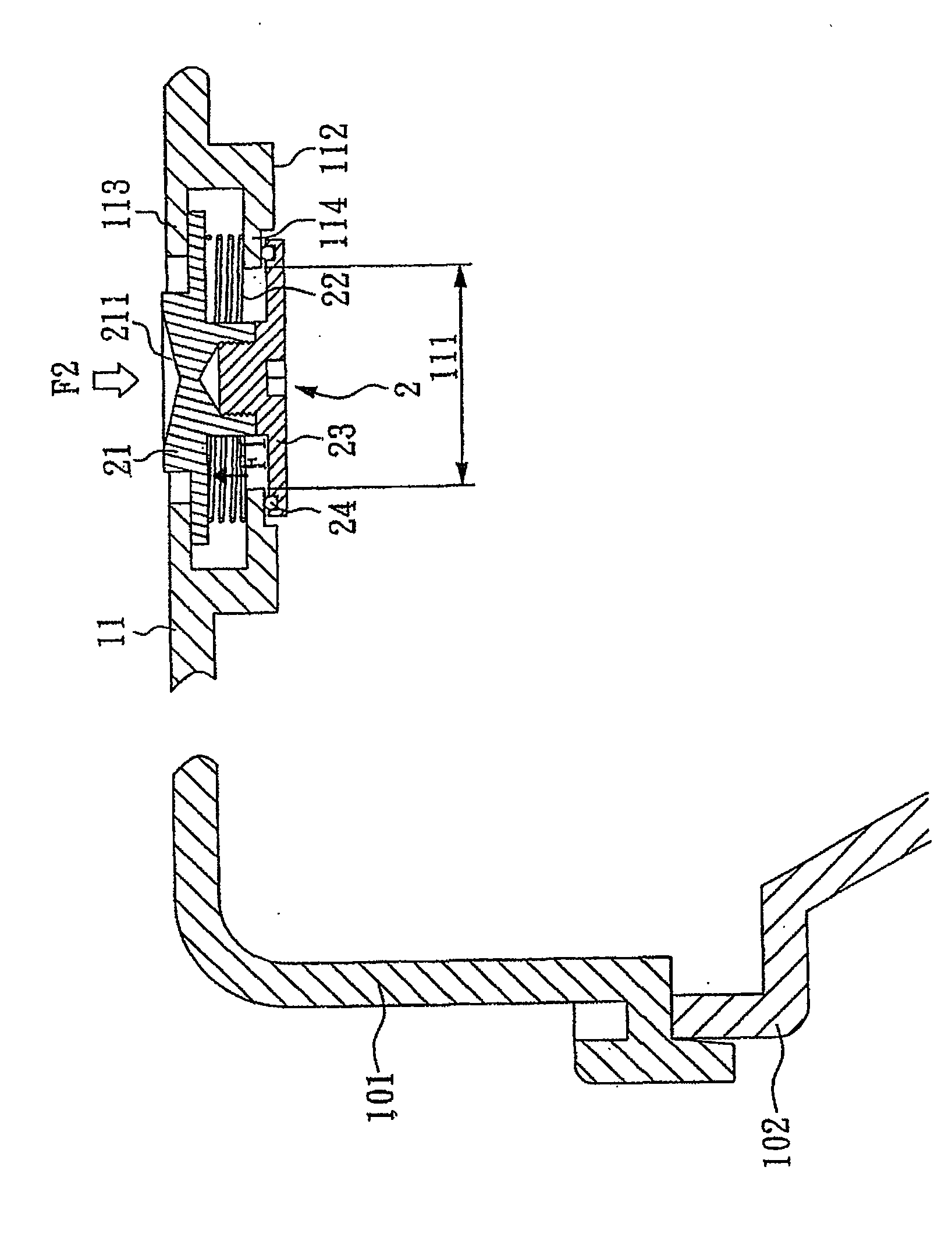

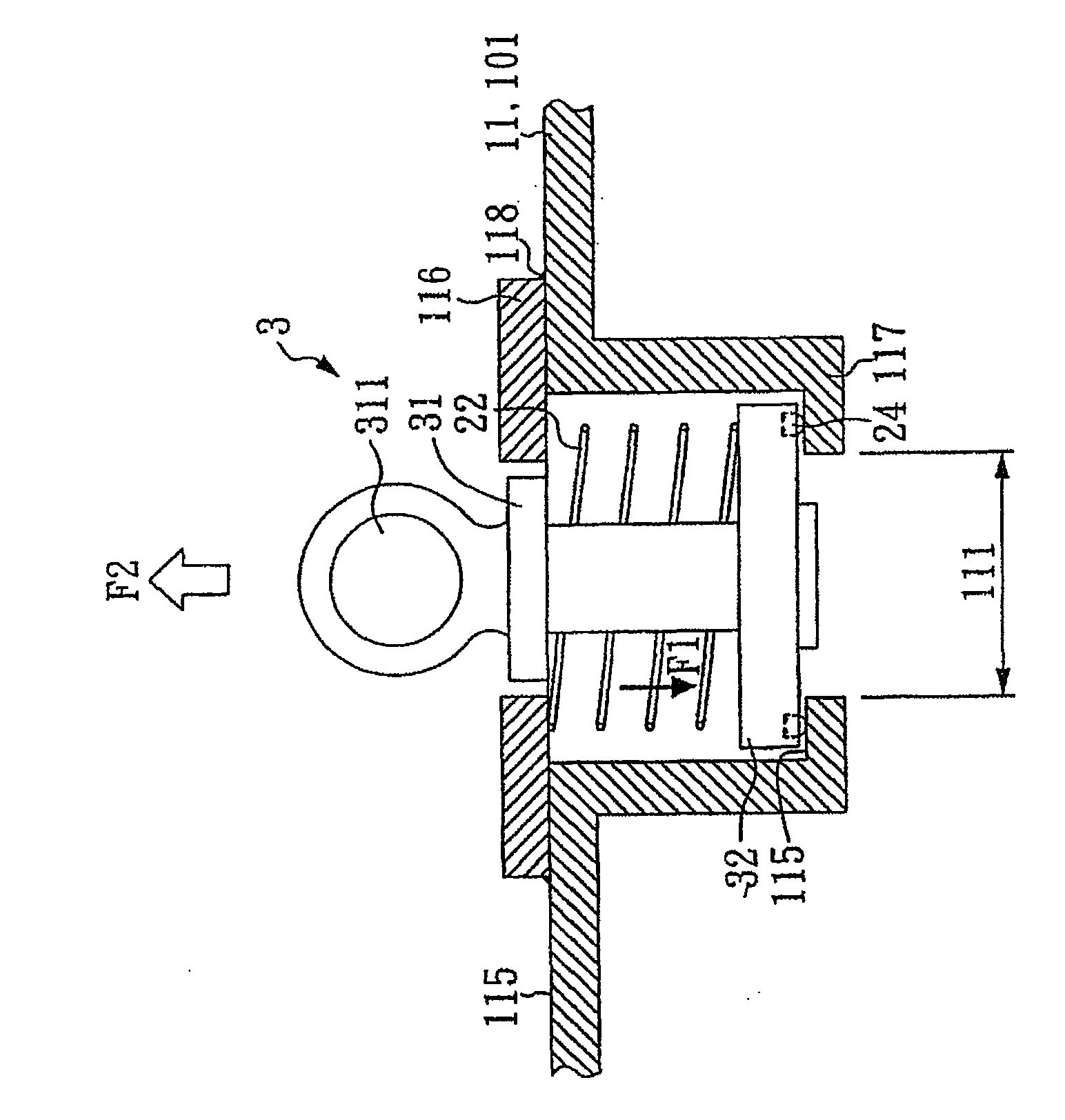

Gripping device

ActiveCN102249146AEliminate the risk of damageConveyor partsLoad-engaging elementsEngineeringMechanical engineering

Owner:KRONES AG

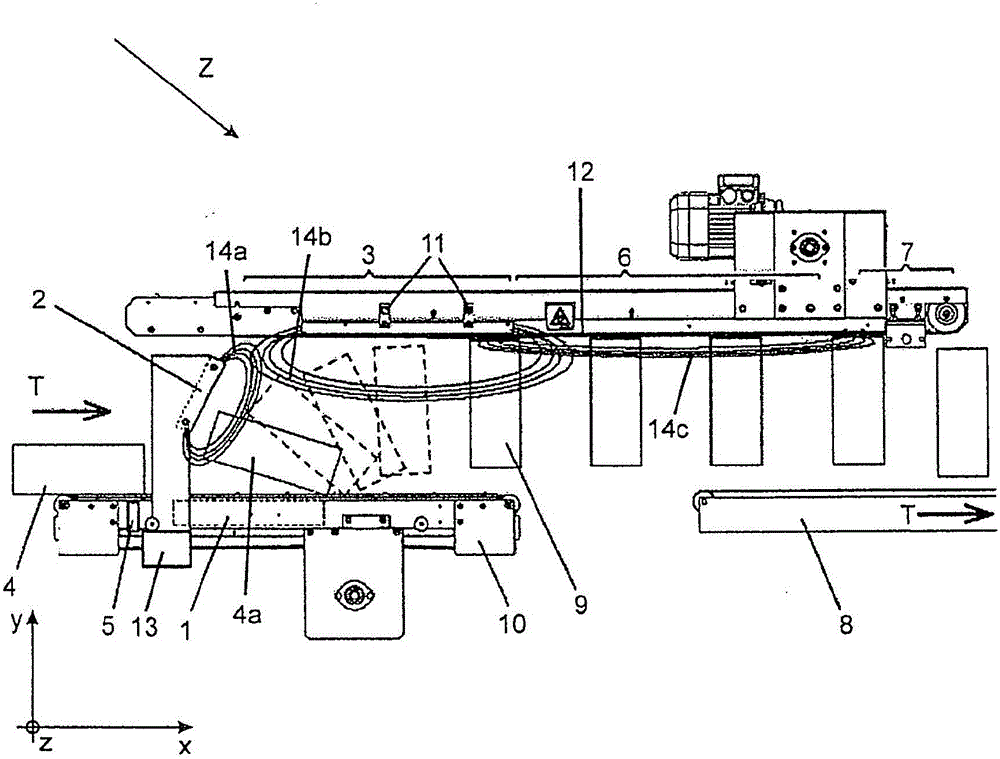

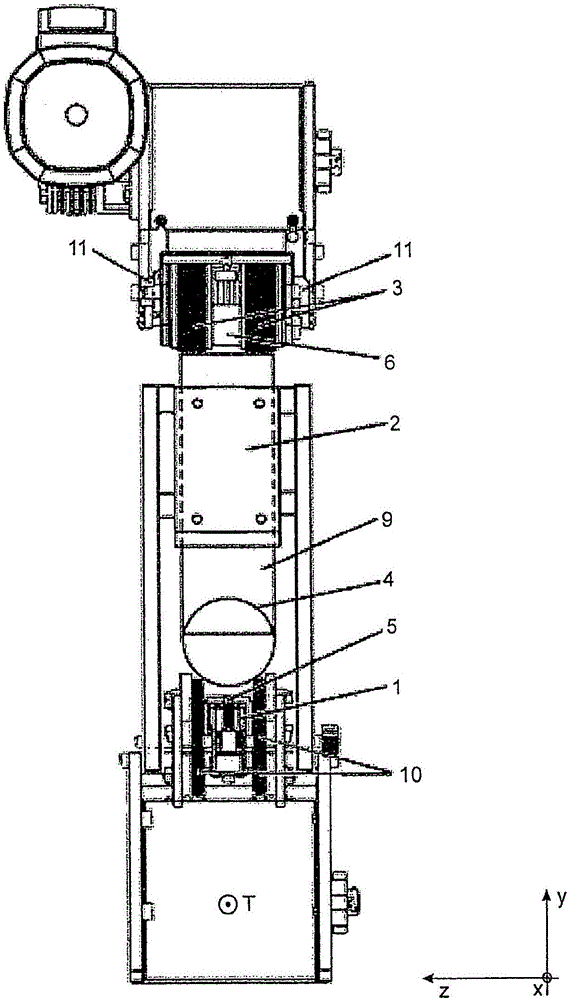

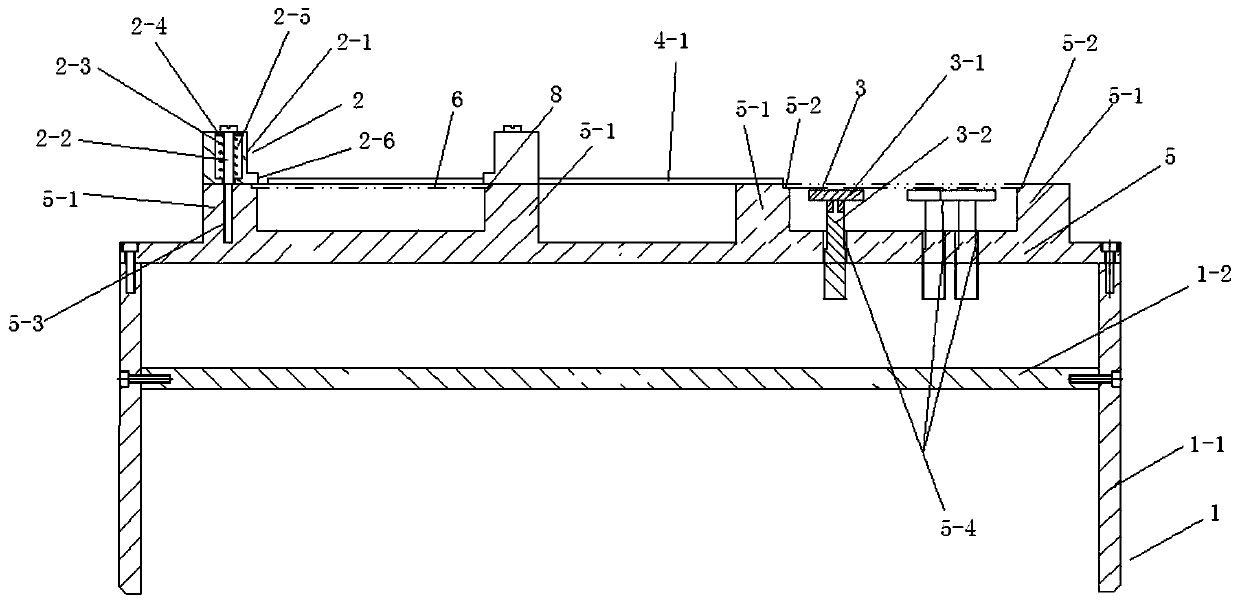

Magnetic standing-up apparatus for can bodies

ActiveCN106458457AEliminate the risk of damageEasy to observeConveyorsConveyor partsFront edgeMechanics

A magnetic can-body standing-up apparatus (Z) comprises an inlet transporting device (10) for conveying lying can bodies (4), a transporting device (12) arranged above the inlet transporting device (10) for conveying upright can bodies (9) hanging on the transporting device (12), and a controller (13). A first magnet arrangement (1) which is activatable and deactivatable in a manner controllable by the controller (13) is arranged below the inlet transporting device (10) in such a manner that a can body (4) lying on the inlet transporting device (10) is magnetically securable in a releasable manner on the inlet transporting device (10). A second magnet arrangement (2) is arranged above a region of the inlet transporting device (10) in which the can bodies are transported and is configured in such a manner that a can body (4) lying on the inlet transporting device (10) can be lifted up by means of the magnetic field of the second magnet arrangement (2) when the magnetic field of the first magnet arrangement (1) is deactivated. A third magnet arrangement (3) is provided above the transporting device (12) and is configured and arranged in such a manner that a can body (4a) which has been lifted up can be lifted up further and can be lifted off the inlet transporting device (10) and can be transported upright hanging magnetically on the transporting device (12). The controller (13) is configured in order to activate the first magnet arrangement (1) when a front edge of a can body (4) lying on the inlet transporting device (10) passes the second magnet arrangement (2) and in order to deactivate the first magnet arrangement (1) when a trailing edge of said can body (4) comes to lie under the second magnet arrangement (2).

Owner:SOUDRONIC

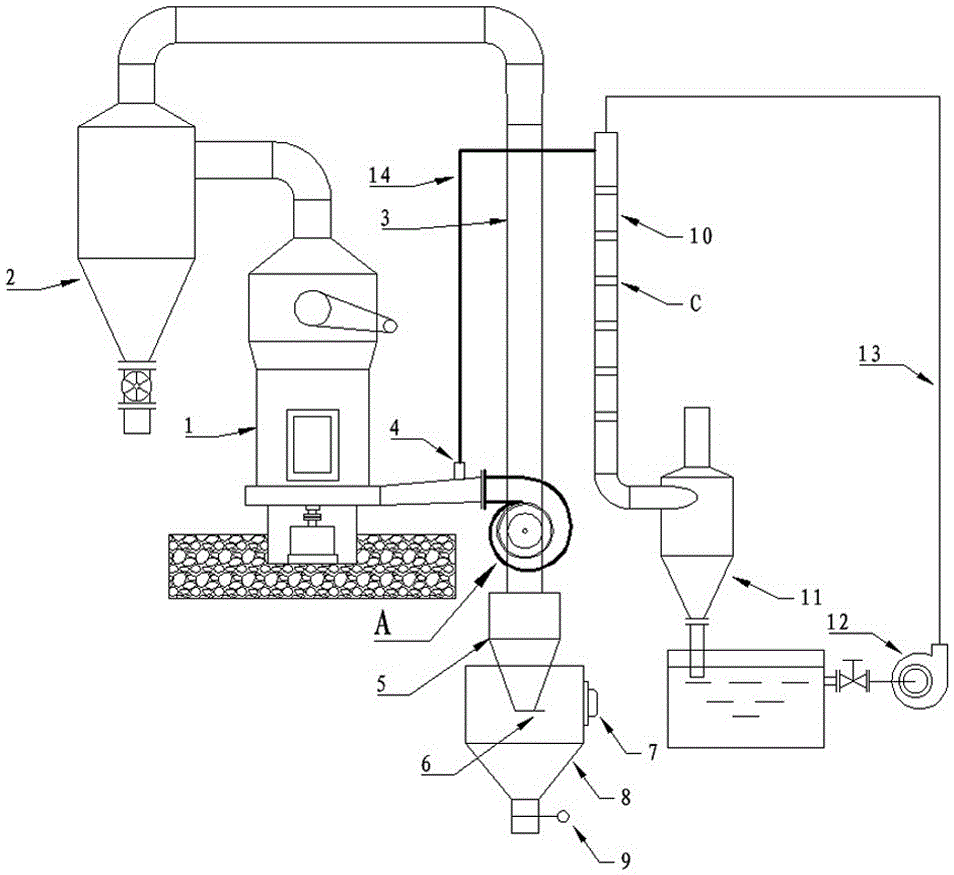

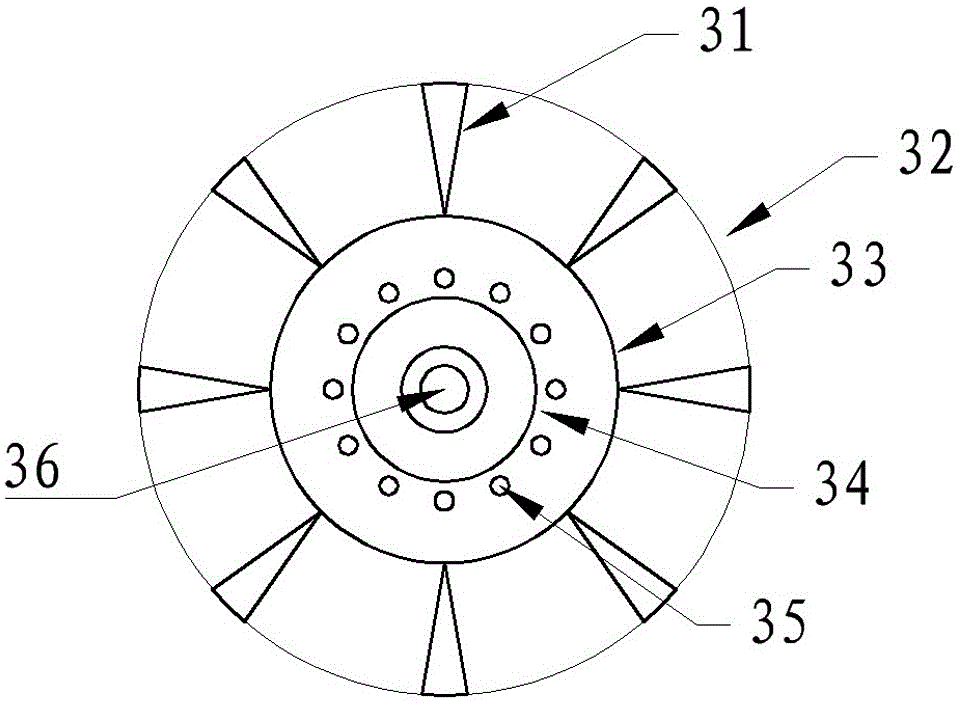

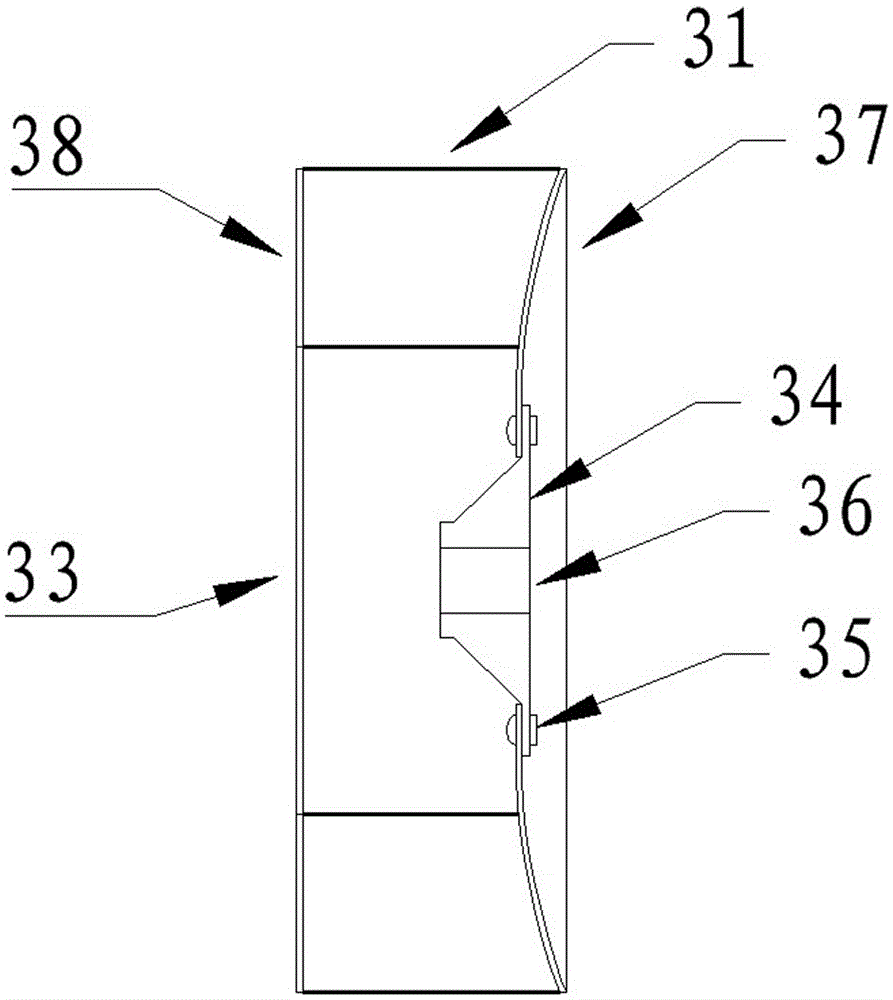

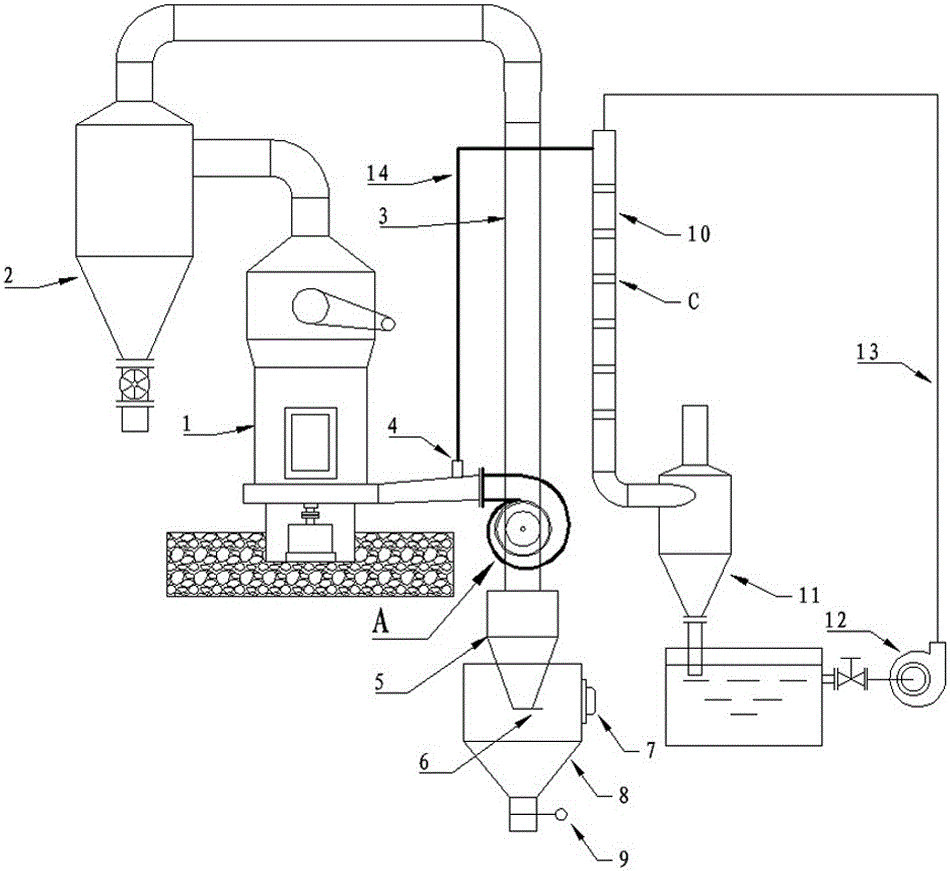

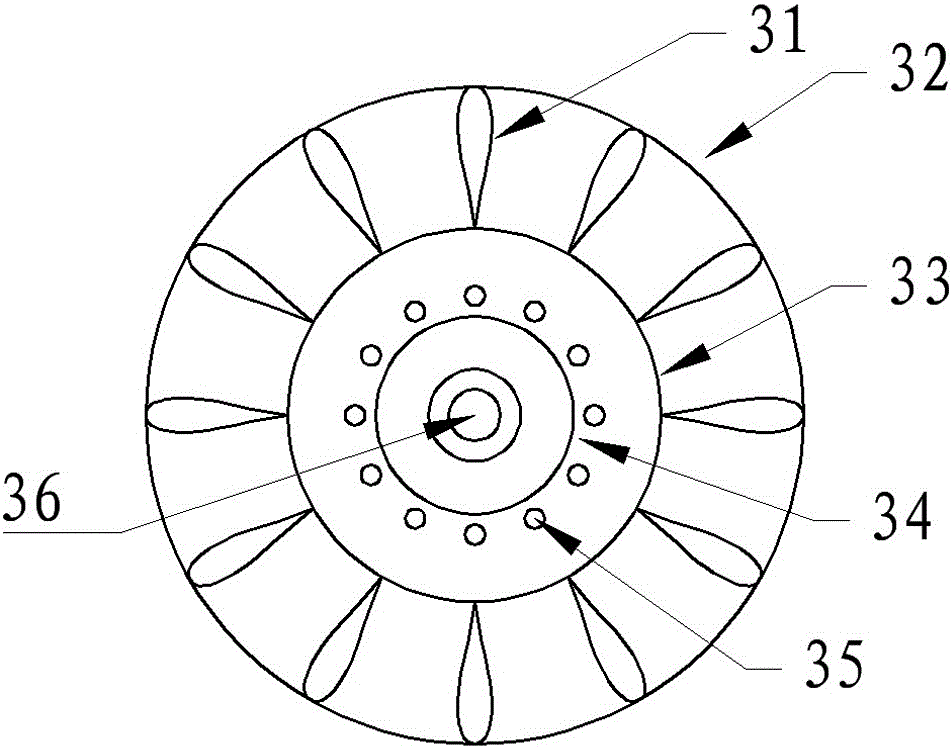

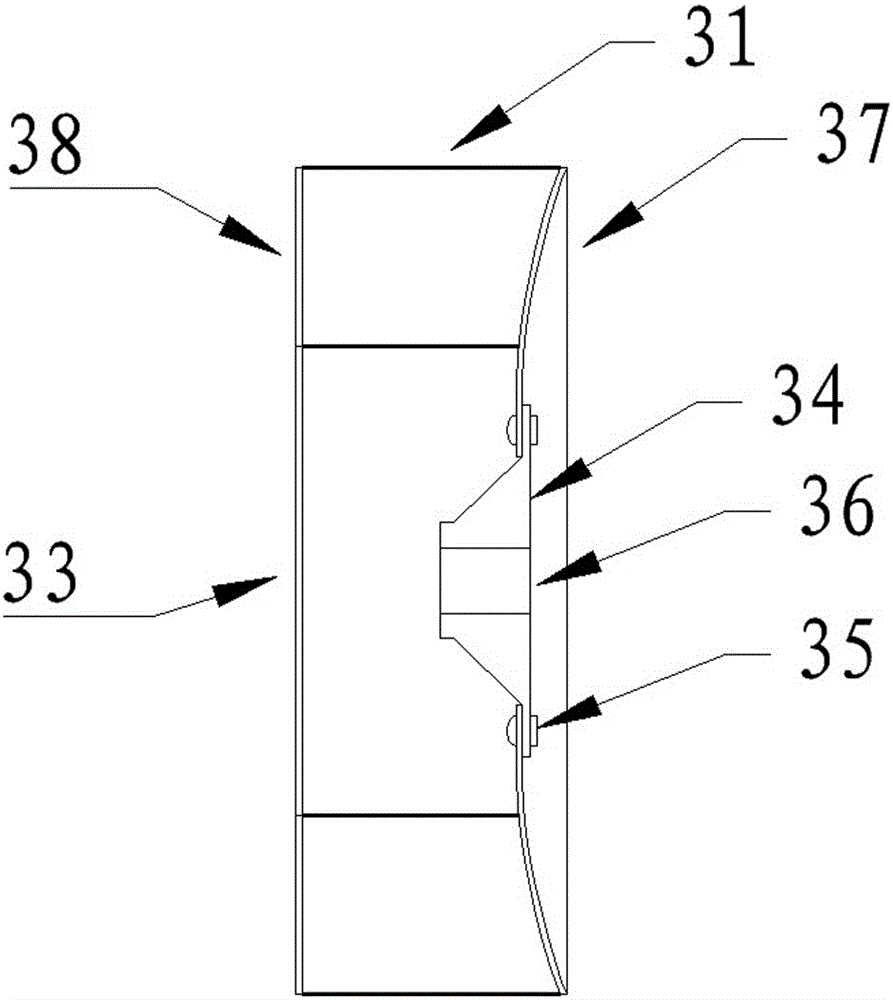

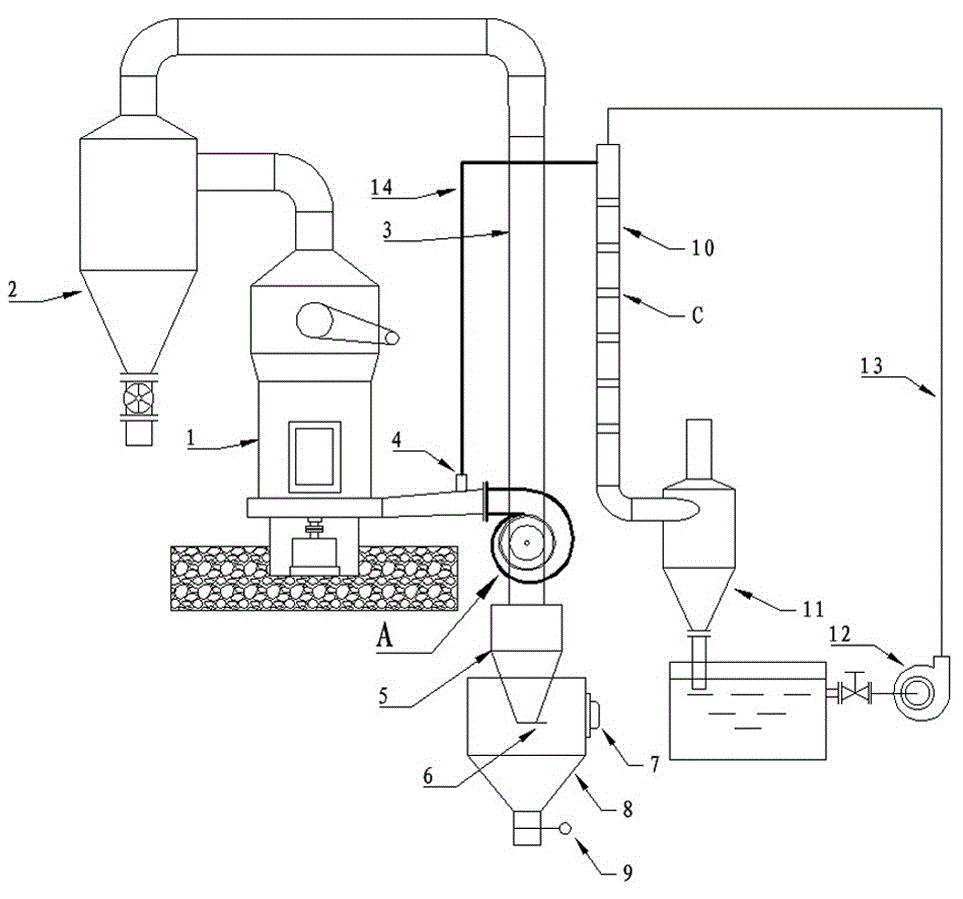

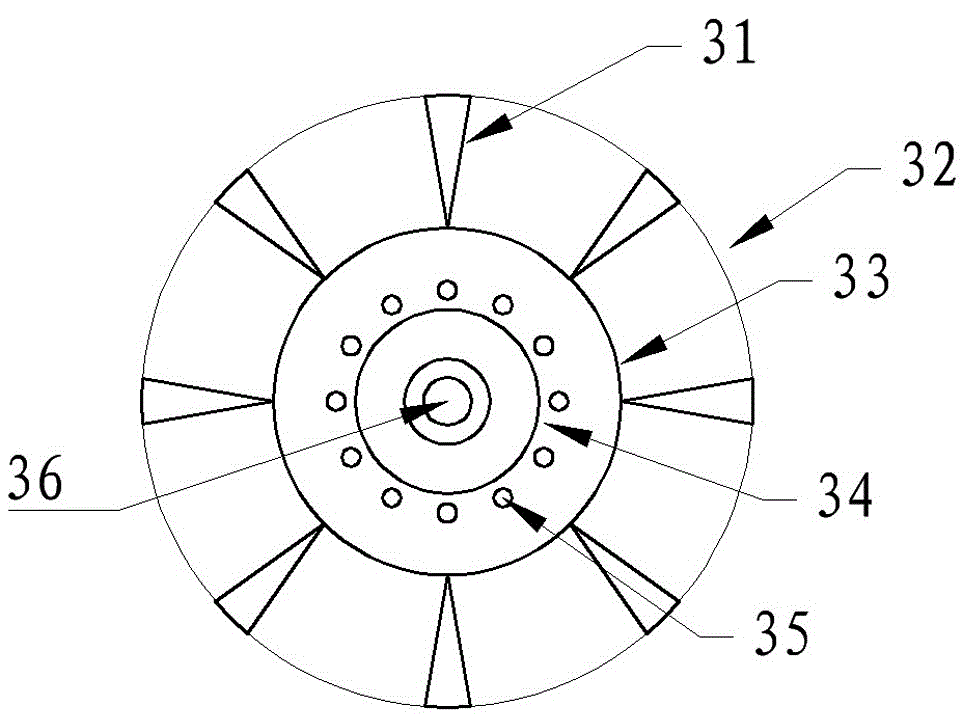

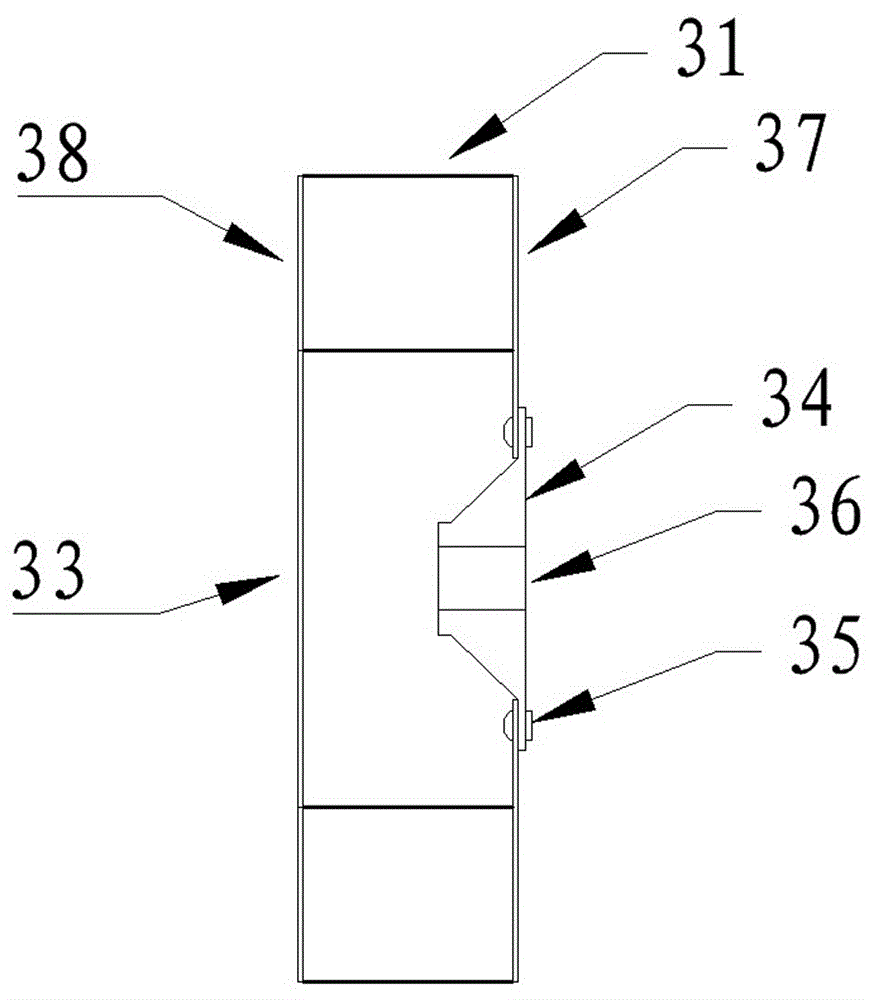

Raymond mill system with draught fan free of dust retention

The invention discloses a Raymond mill system with a draught fan free of dust retention. An air current circulation milling discharging system is formed by the draught fan, a Raymond mill, a cyclone separation discharging device and an air return duct; a pressure-equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe, multiple cyclones are arranged in the cyclone pipe, the lower end of the cyclone pipe is connected with a cyclone separator in the tangent direction, and a lower pipe orifice of the cyclone separator immerges into a circulation water tank which is connected with the upper end of the cyclone pipe; and an impeller of the draught fan is of a structure that blades are in a hollow and wedged shape and the backing plate is in a disc shape, and the contour line of the appearance of the draught fan is an evolvent. According to the Raymond mill system with the draught fan free of the dust retention, due to the fact that the cyclone pipe and the cyclones are arranged, low-resistance pressure-equalizing exhaust is achieved, and dust overflow caused by positive pressure of the system is eliminated; by means of the circulation water tank, wet-method high-efficiency dust removal and mineral powder recycling are achieved; and by means of the structure that the blades are in the hollow and wedged shape and the backing plate is in the disc shape, real-time cleaning of the dust on an impeller of the draught fan is achieved, the impeller strength of the draught fan is increased, the stability is enhanced, safety accidents caused by dust accumulation is effectively eradicated, and the application prospect is wide.

Owner:JISHOU UNIVERSITY

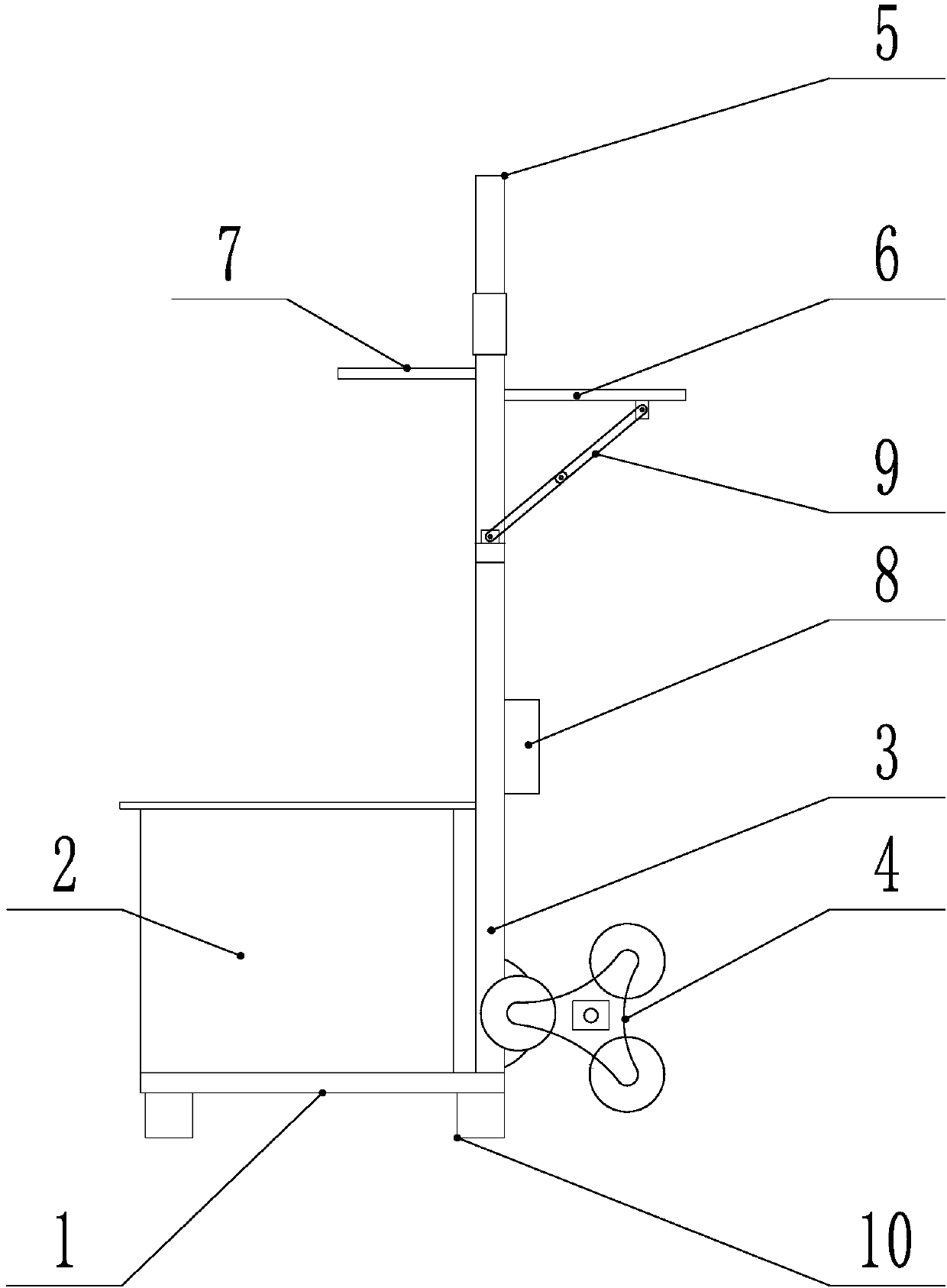

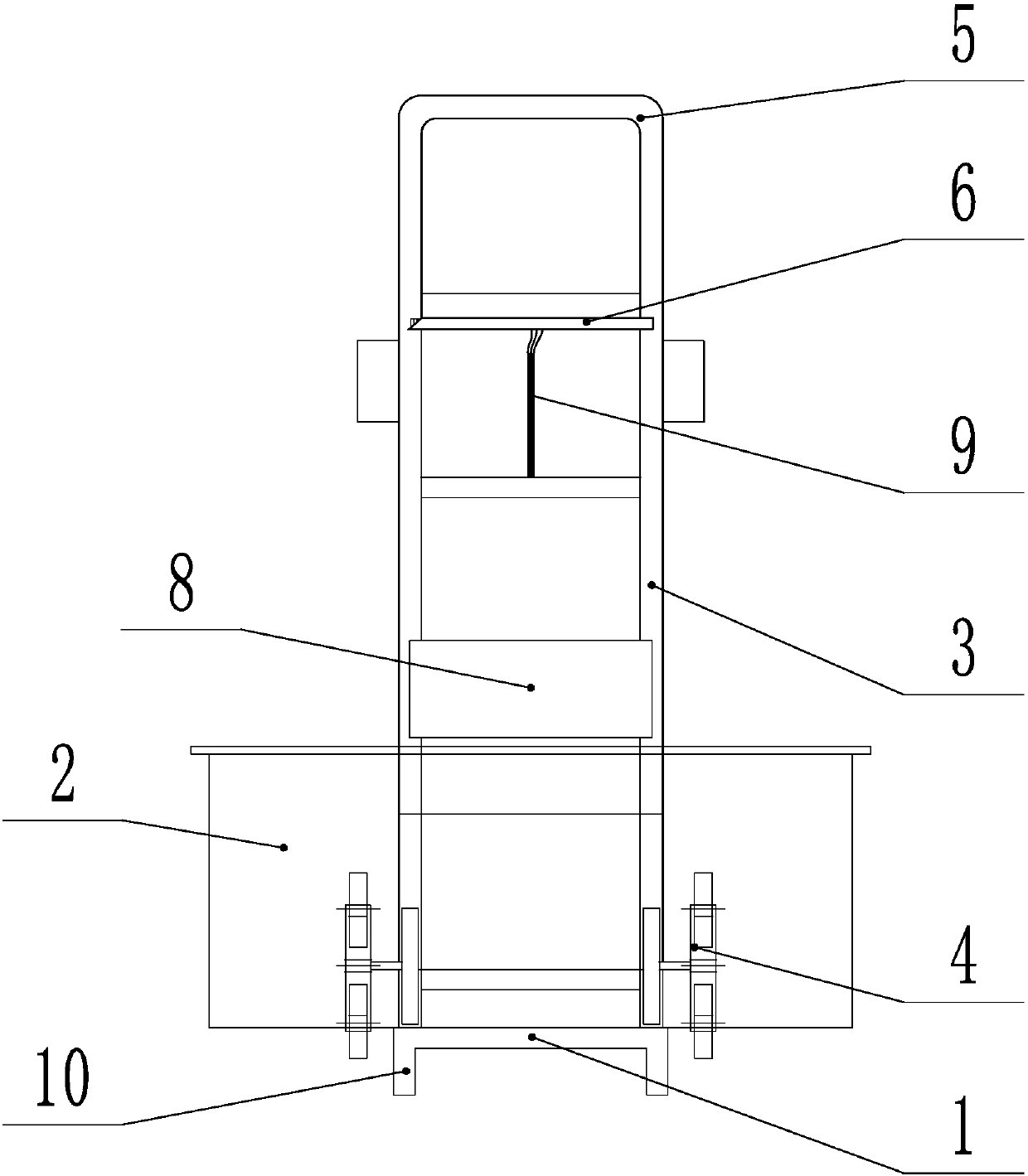

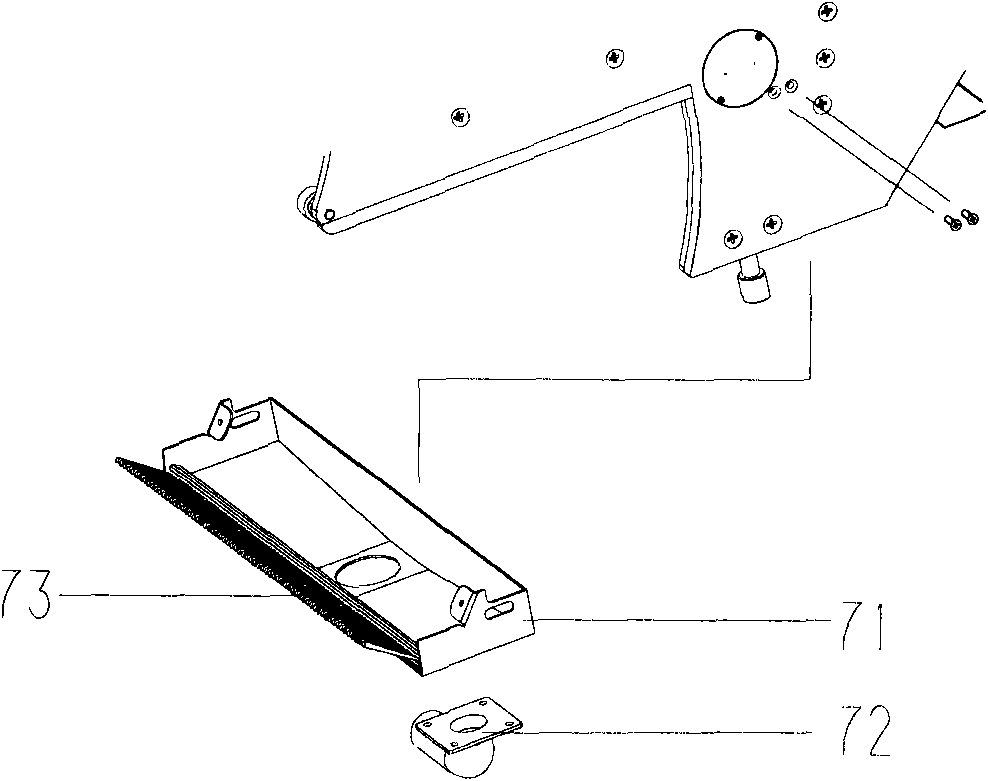

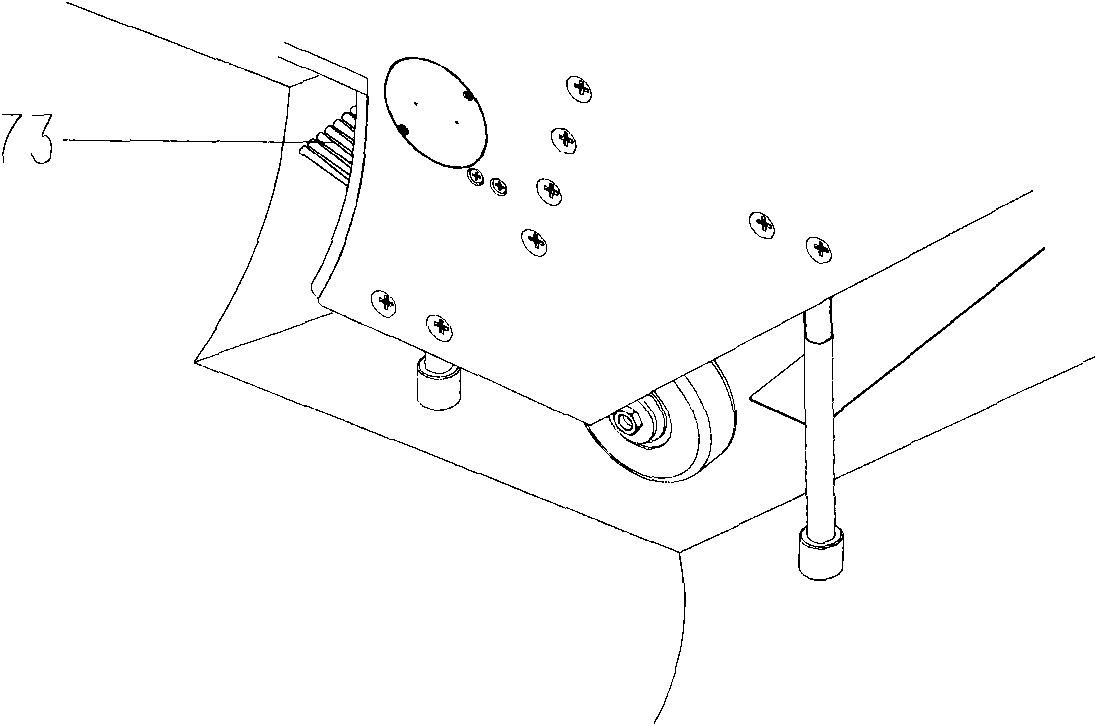

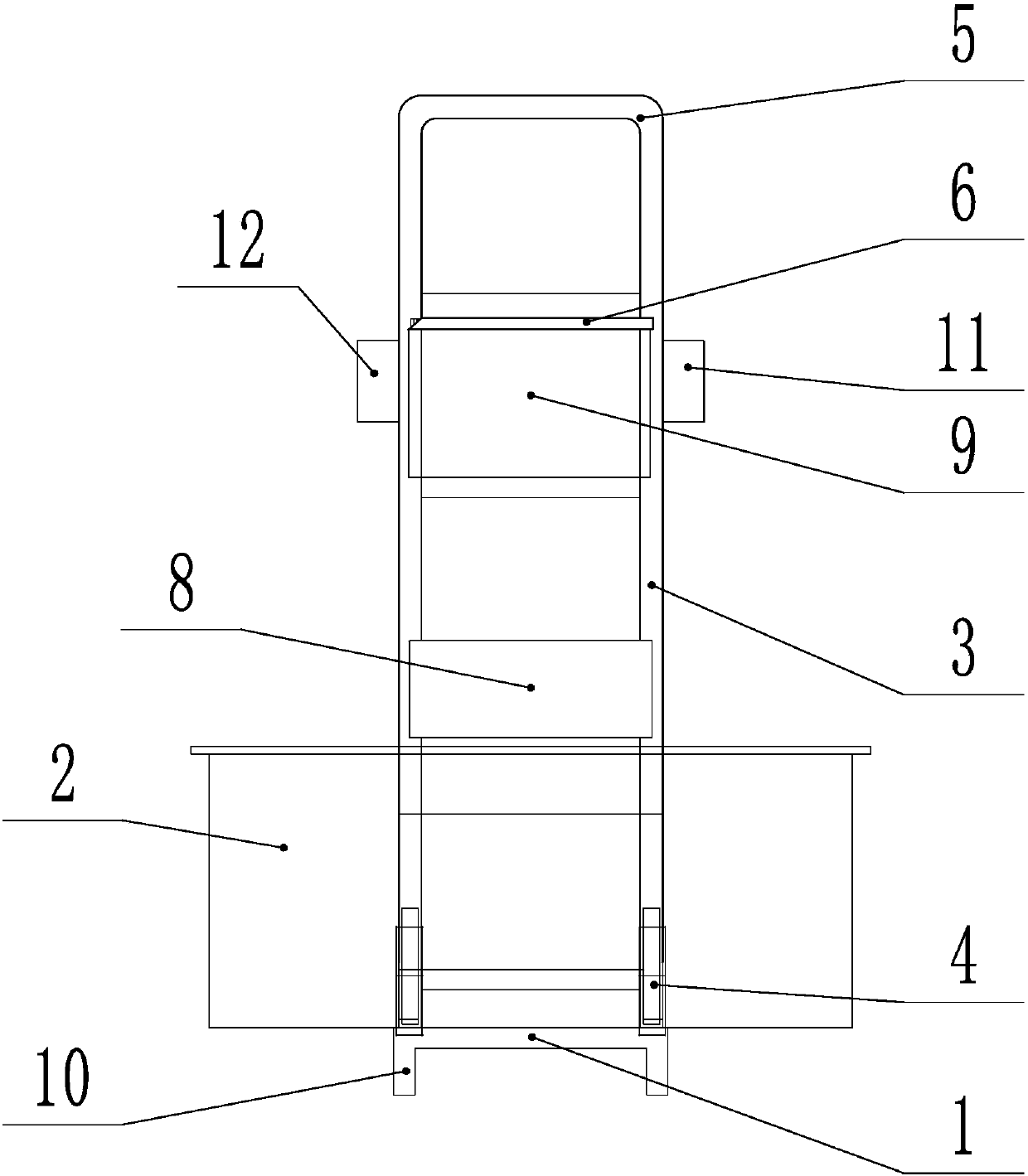

Transformer substation operation and maintenance pull rod tool cart of three-idler-wheel structure

PendingCN107719420AReduce workloadReduce the intensity of handling workHand carts with one axisHand cart accessoriesCartTroubleshooting

The invention provides a transformer substation operation and maintenance pull rod tool cart of a three-idler-wheel structure, and relates to the field of transformer substation operation and maintenance. Currently, when power failure and power transmission operation is normally conducted, a tool chamber is far from a primary equipment area, many operation tools exist and need to be carry many times, and the additional workload of operation team personnel is increased. The transformer substation operation and maintenance pull rod tool cart comprises a baseboard, a vertical support, an object storage box, two sets of trundles and a pull handle, an operating ticket clamp is arranged at the right side of the middle of the support, an operating ticket platform capable of turning downwards is arranged at the right side of the upper portion of the support, an insulating rod electroscope placing platform is arranged at the left side of the upper portion of the support, both sets of trundles are of the three-idler-wheel structure in which every two idler wheels are spaced by 120 degrees in a vertical plane, and one idler wheel is connected to the right side of the lower portion of the support; a two-connecting rod foldable supporting structure is arranged between the lower portion of the operating ticket platform and the support. By means of the transformer substation operation and maintenance pull rod tool cart of the three-idler-wheel structure, carrying multiple tools is achieved simultaneously, a multifunctional processing platform is provided, the carrying workload is reduced,the carrying work intensity is lowered, so that an operation and maintenance fault is more conveniently processed, and the processing time is shortened.

Owner:DAISHAN POWER SUPPLY CO STATE GRID ZHEJIANG ELECTRIC POWER CO +2

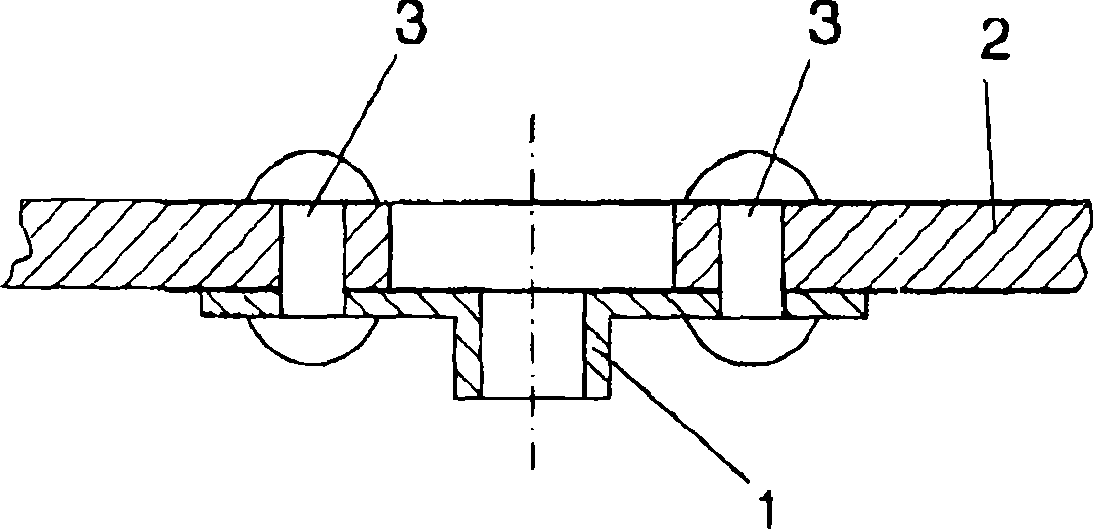

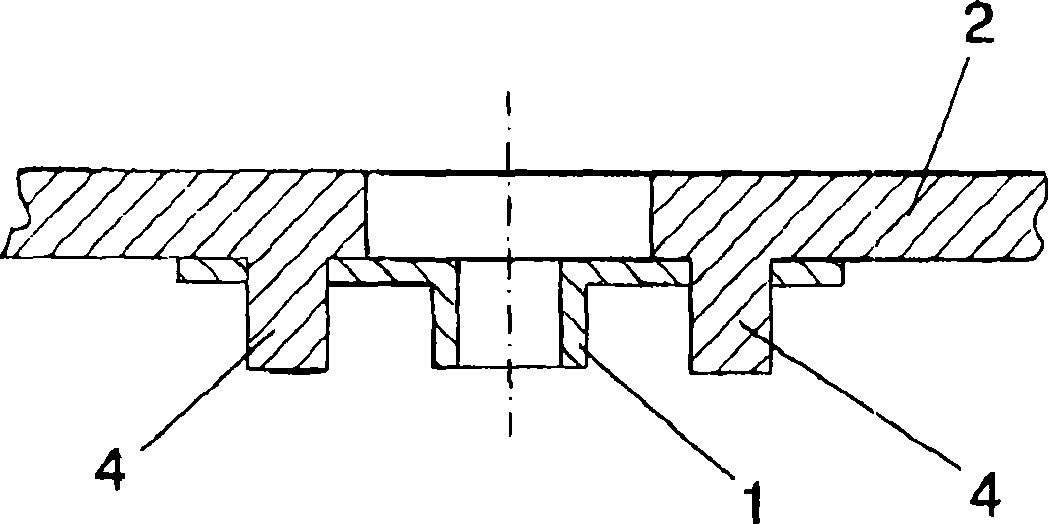

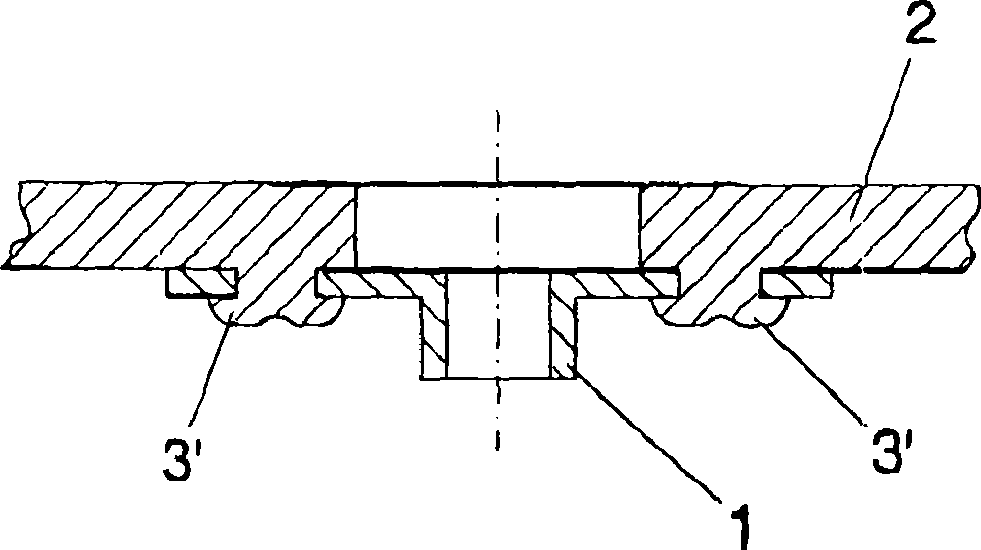

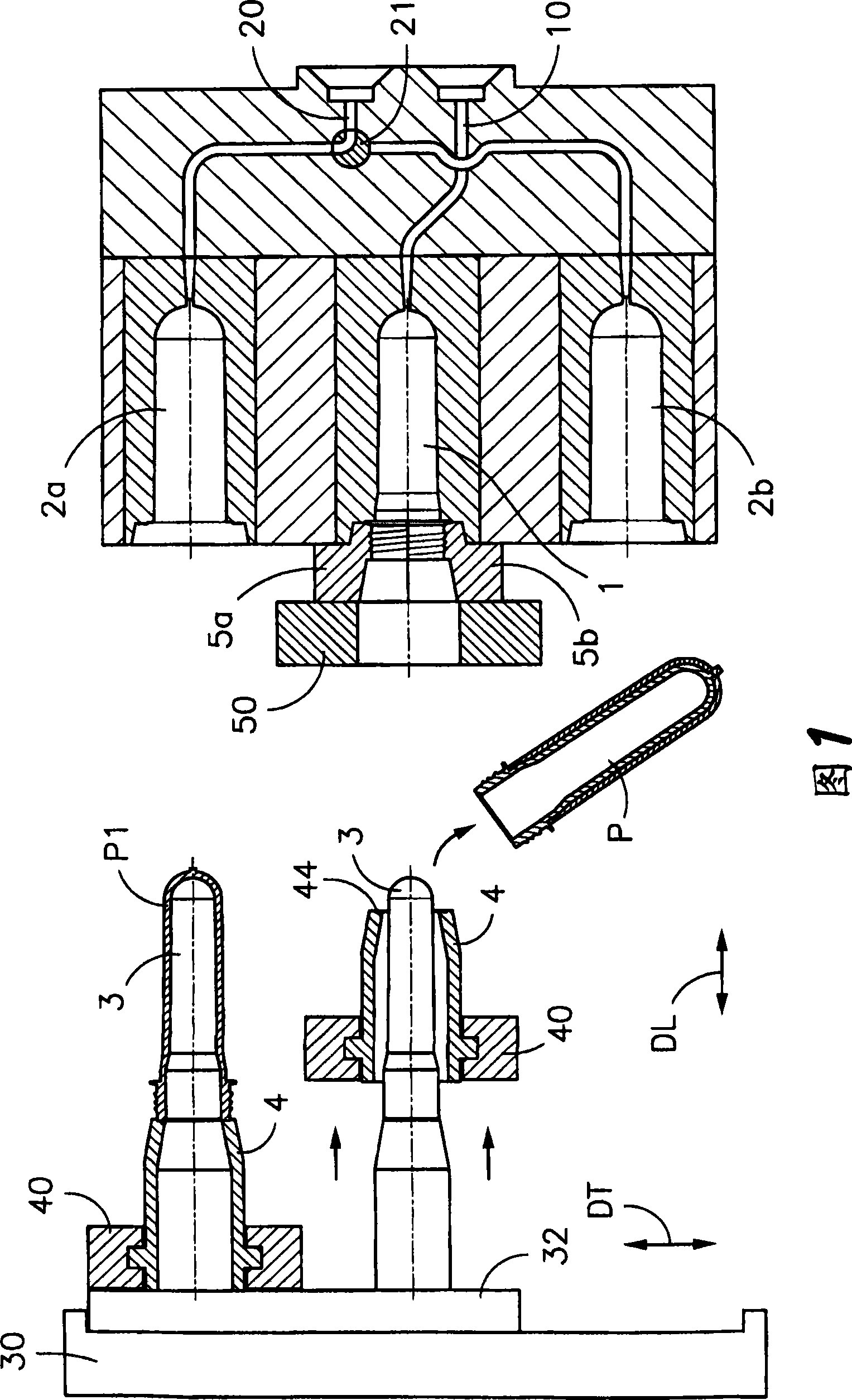

System for integrating rivet nuts into plastic components

InactiveCN101469734ALow costEliminate the risk of damageNutsDomestic articlesPlastic materialsEngineering

A system for combining a riveting nut to a plastic material component fixes a metal riveting nut (1) on a plastic component (2), so as to connect the plastic component to other components; wherein the other components are metallic or nonmetallic. Preferably, the plastic component (2) manufactured by an injection mold comprises a plurality of noses (4) for riveting the riveting nut (1), and the noses (4) perforate the holes particularly arranged inside the riveting nut (1).

Owner:AIRBUS OPERATIONS SL

Waste recovery box for automatic ladder step cleaning equipment

The invention discloses a waste recovery box for automatic ladder step cleaning equipment, which is arranged on a position in the step cleaning equipment opposite to the lower side elevation of the current cleaned step. The waste recovery box is characterized by comprising a waste box and a seal brush which extends from the bottom edge of the waste box facing one side of the step elevation to the elevation, wherein the extending direction of the seal brush is an inverse gravity direction, and the end part of the seal brush is provided with sealing teeth matched with the grid-tooth shaped elevation; and a transition tube for externally connecting a drain tank is arranged at the depressed position on the bottom of the waste box. Application of the waste recovery box ensures that the automatic ladder step cleaning equipment can effectively collect and guide sewage generated when the current step is cleaned by closely attaching the step elevation to the matched seal brush in actual work, so that the sewage can completely flow into the waste box, and secondary pollution of the cleaning sewage to the automatic ladder and potential danger of electric control unit damage can be remarkably eliminated.

Owner:苏州科莱尼机电科技有限公司

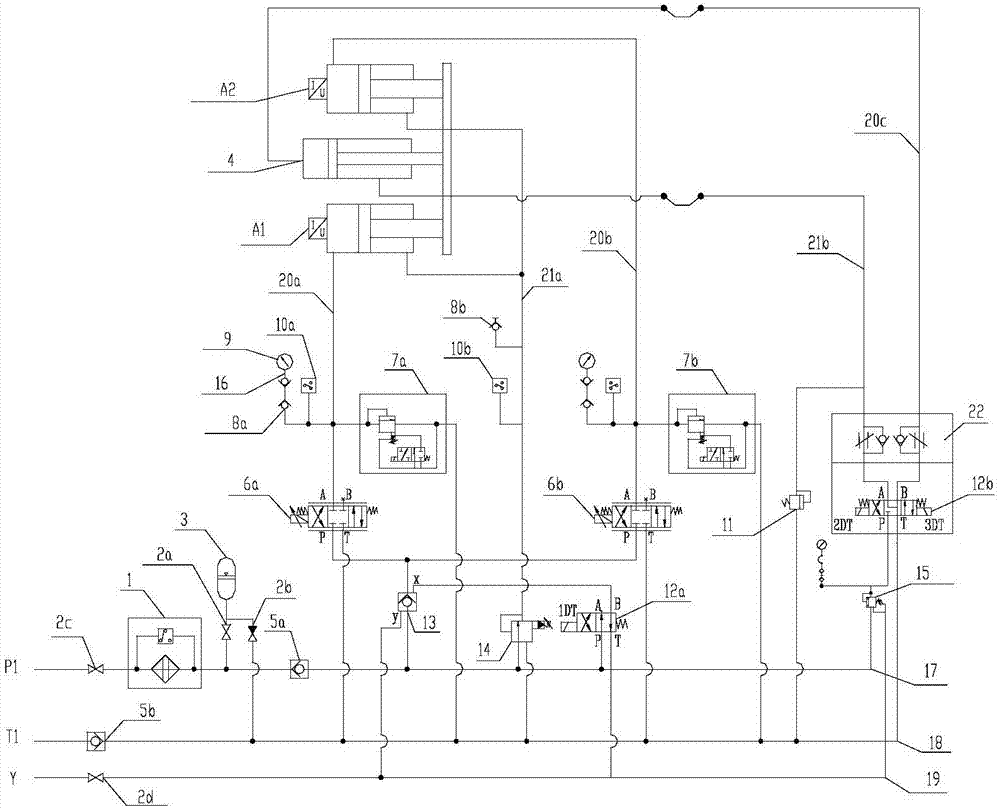

Hydraulic system of AWC servo device

ActiveCN107387507AReduce matingHighly integratedFluid-pressure actuator safetyFluid-pressure actuator testingSystem integrationHigh pressure

The invention provides a hydraulic system of an AWC servo device. The hydraulic system of the AWC servo device comprises an oil inlet pipeline, an oil return pipeline and an oil drainage pipeline, wherein a third high-pressure ball valve, a high-pressure filter and a first one-way valve are mounted on the oil inlet pipeline; the tail end of the oil inlet pipeline is divided into two channels; one channel is connected to a first rod cavity oil tube while the other channel is connected to a second rod cavity oil tube; a second one-way valve is arranged on the oil return pipeline; the tail end of the oil return pipeline is divided into three channels; the first channel is connected to a first rodless cavity oil tube; the second channel is connected to a second rodless cavity oil tube; the third channel is connected to a third rodless cavity oil tube; the oil drainage pipeline is provided with a fourth high-pressure ball valve; and a first solenoid directional valve and a pilot operated check valve which are connected in parallel are arranged between the oil drainage pipeline and the oil inlet pipeline. By the hydraulic system of the AWC servo device, control loops of a vertical roll balancing cylinder are integrated together; the system integration degree is high; combination control and adjustment are facilitated; matched pipelines of equipment are reduced; and unnecessary pipeline leakage points are avoided.

Owner:中重科技(天津)股份有限公司

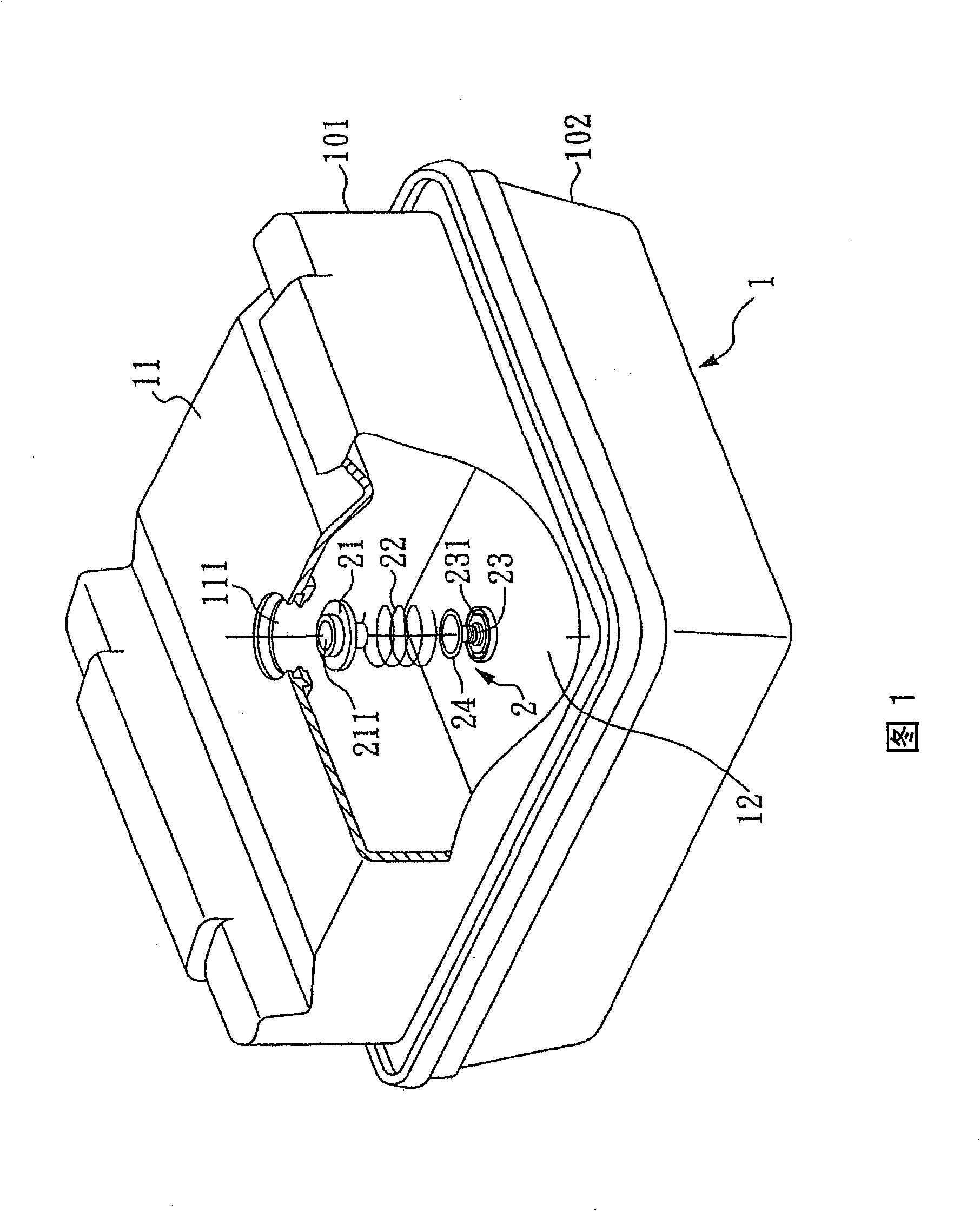

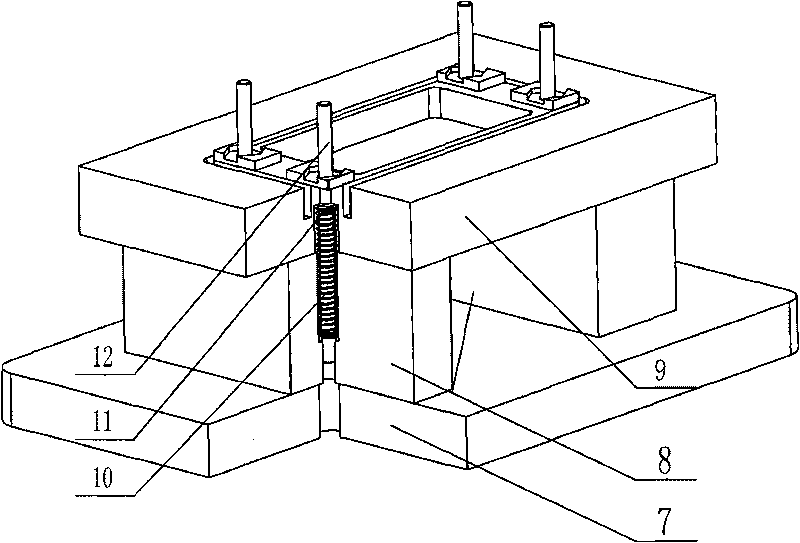

Crystal boat box with inlet valve

InactiveCN101409246AEliminate the risk of damageEasy to openClosuresSemiconductor/solid-state device manufacturingElastic componentInlet valve

The invention relates to a wafer cassette with an air intake valve. The wafer cassette comprises a cassette body and an air intake valve. The air intake valve is arranged on a casing of the cassette body and comprises a guide pole, a sealing cover, a sealing gasket and an elastic component. The air intake valve is provided with an elastic prestress by the elastic component to push the guide pole to ensure that the sealing cover covers over a through hole of the casing and ensure that the sealing gasket is pressed between the sealing cover and the casing to form air tightness. When a wafer cassette with vacuum at the inside is opened, only outside force is required to push the guide pole reversely to ensure that a gap is produced between the sealing cover and the casing, at the time, outside air enters into the inner space of the cassette body in a way that stream guidance passes through the gap by the through hole, so that the air pressures inside and outside the cassette body are balanced to be good for opening a cassette cover easily.

Owner:KING YUAN ELECTRONICS

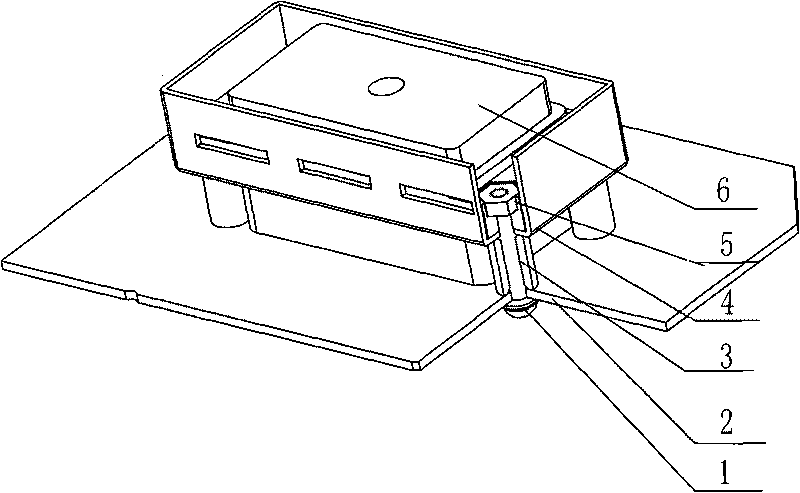

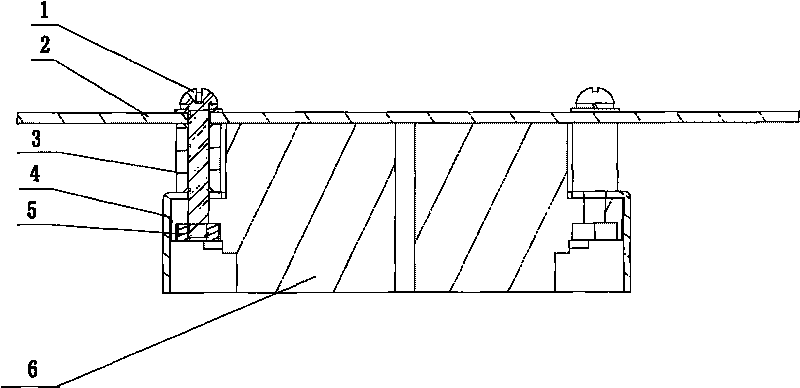

Shielded ultrasound probe socket and assembling jig thereof

ActiveCN101694483AAvoid hidden dangers such as poor contactAssembly positioning is accurateMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound probe

The invention discloses a shielded ultrasound probe socket which comprises an ultrasound probe socket, an open ultrasound probe socket shielded box and an ultrasound probe socket circuit board, wherein the ultrasound probe socket is fixed on the ultrasound probe socket circuit board, and the open ultrasound probe socket shielded box surrounds the ultrasound probe socket. The shielded ultrasound probe socket also comprises screws, nuts and cylindrical support columns, wherein at least one nut clamping groove is respectively arranged at both ends of the ultrasound probe socket, the number of the screws, the nuts and the cylindrical support columns corresponds to the number of the nut clamping grooves, each nut is placed in each nut clamping groove, each cylindrical support column is positioned between the ultrasound probe socket circuit board and the open ultrasound probe socket shielded box, each screw passes through the through hole in the ultrasound probe socket circuit board, then passes through the cylindrical support column, and then passes through the through hole of the open ultrasound probe socket shielded box, and finally is screwed into the nut.

Owner:深圳蓝影医学科技股份有限公司

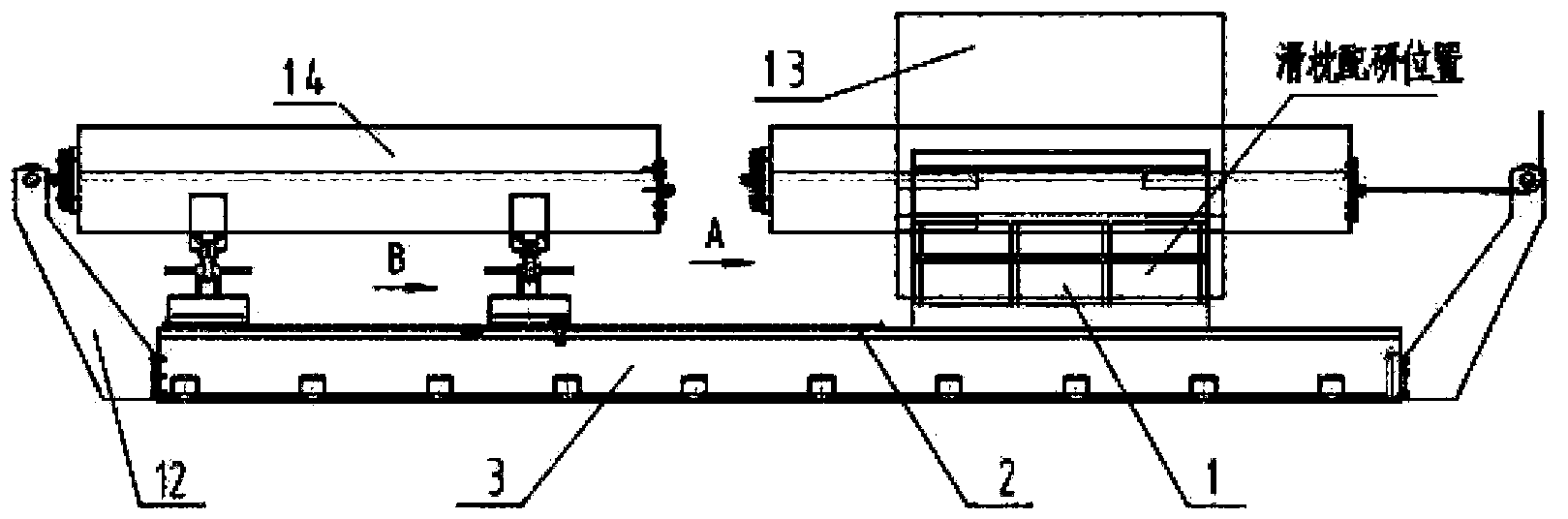

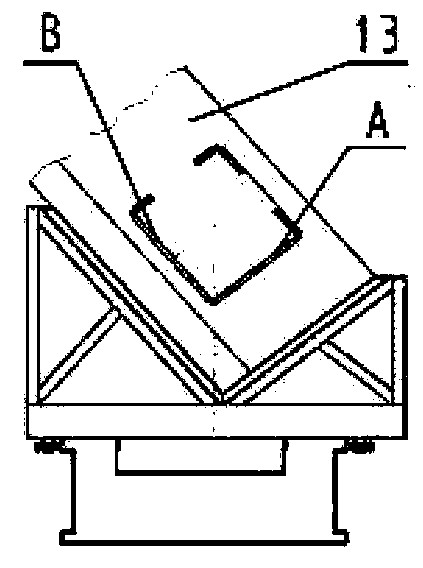

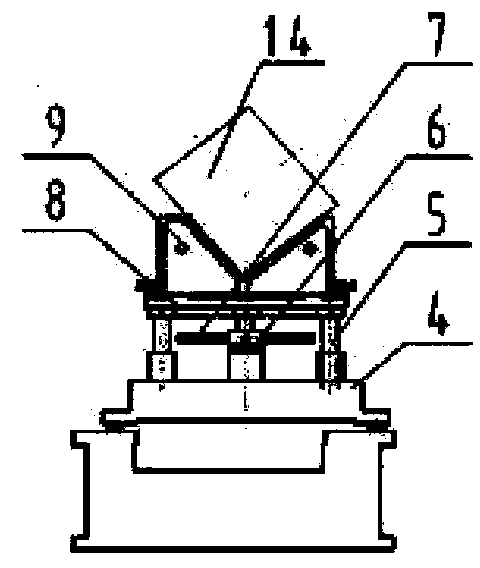

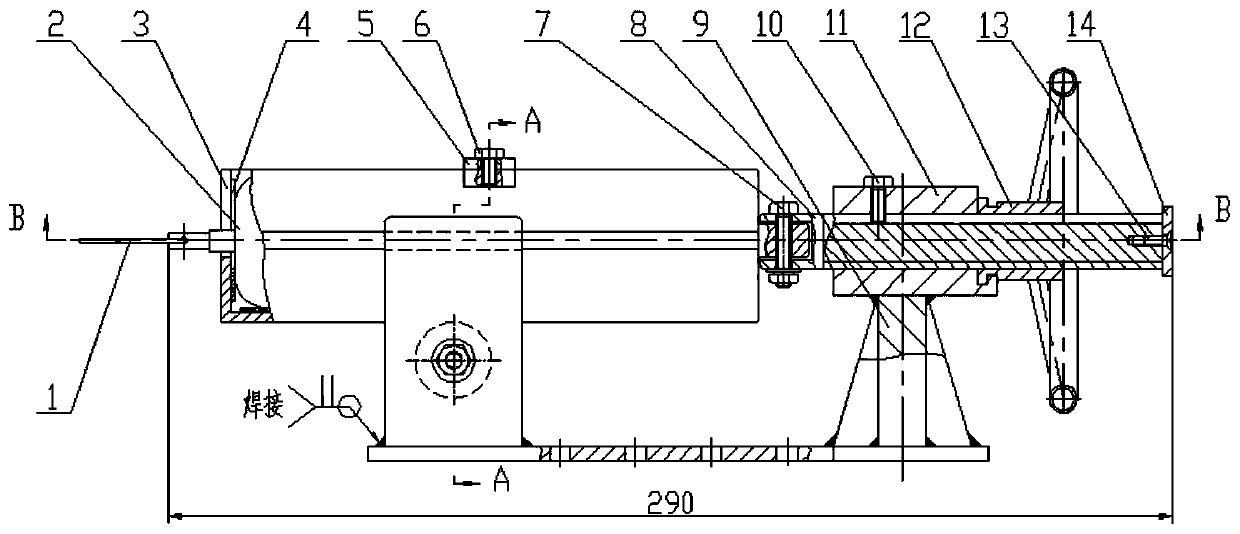

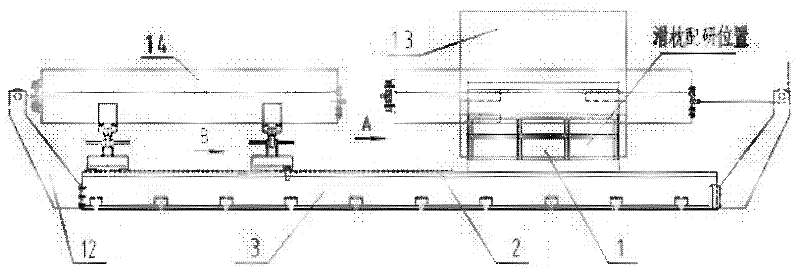

Assembling and scraping method of spindle box square hole assembling and scraping device

The invention discloses an assembling and scraping method of a spindle box square hole assembling and scraping device. The process is as follows: a moving seat is pushed, so that a ram part moves stably on a precision linear guide track to a position near the front end of a spindle box; a handle on a ram support adjusting mechanism is rotated, and a center of the ram part and a square hole center of the spindle box are enabled to be equal in height by the aid of a lead screw nut adjusting mechanism; a traction cable is connected with two ends of the ram part, bypasses a fixed pulley on a traction pulley support, and is connected with a lifting hook of a travelling crane; the ram part is pushed into a square hole of the spindle box; and the ram part is pulled forward and backward through the movement of the lifting hook on the travelling crane, and assembling and scraping are performed. With the adoption of the technical scheme, the production efficiency is improved, a potential danger that the ram part collides into the spindle box, so that a workpiece is bumped or damaged is eliminated, the manufacturing accuracy of a product is improved, the product quality is greatly improved, and human power and material resources are saved.

Owner:WUHU HENGSHENG HEAVY MACHINE TOOL

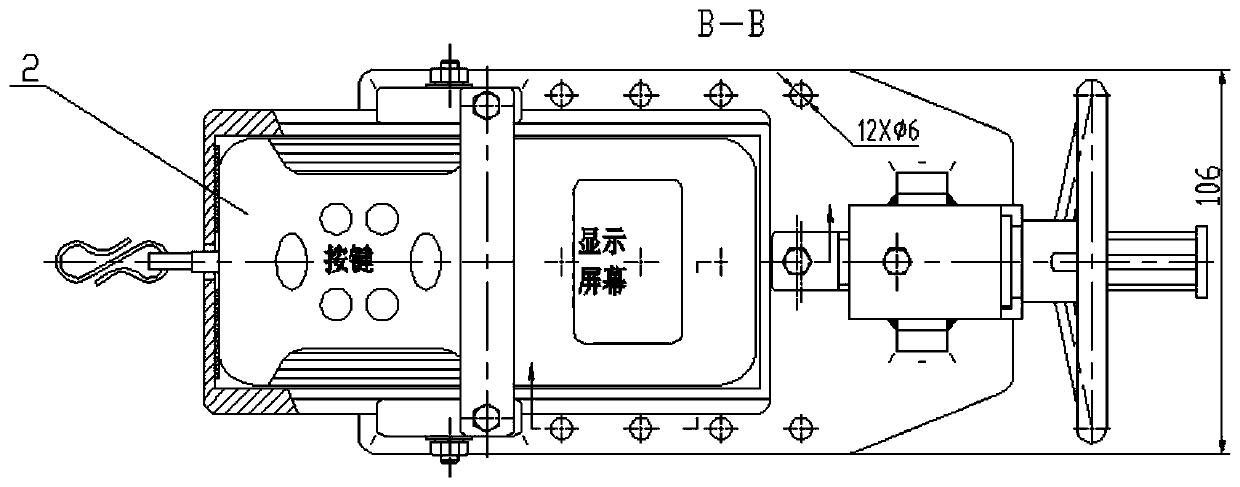

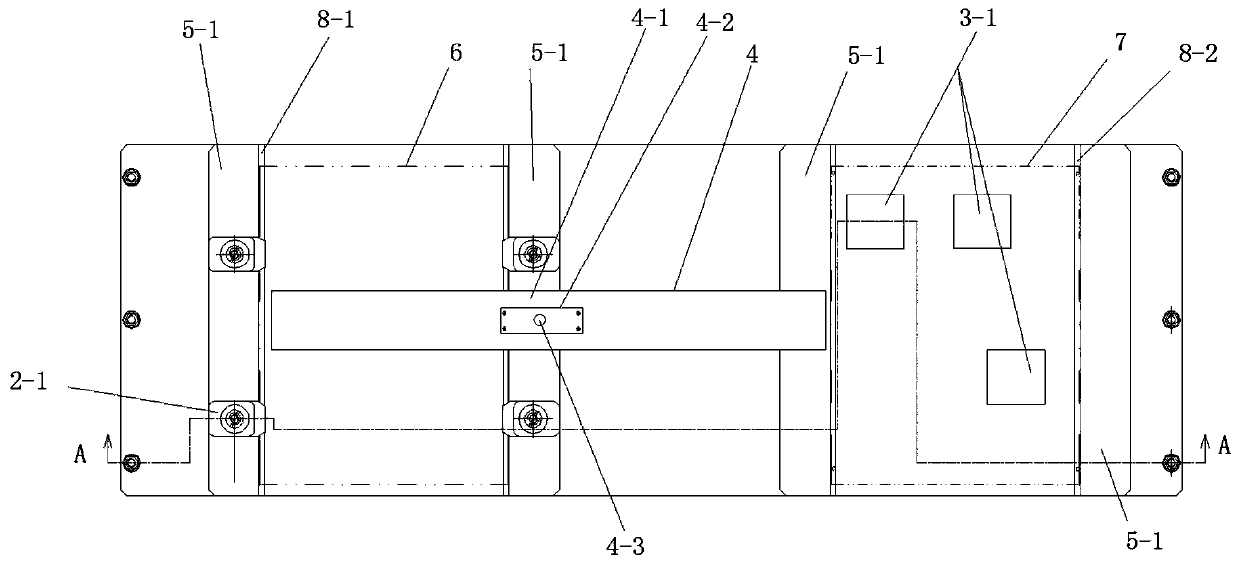

Pull-out force test device

PendingCN109827690AAchieve peak holdEasy to readMachine part testingApparatus for force/torque/work measurementElectricityEngineering

The invention relates to the technical field of mechanical structures and particularly relates to a pull-out force test device. The device provided by the invention comprises a base, a force measuringcomponent, a pull-out linkage component, a first supporting component and a second supporting component. The force measuring component comprises a dynamometer box and a force gauge set in the dynamometer box which is horizontally movably disposed on the first supporting component, a force measuring end of the dynamometer is connected to a hook, and the hook is connected to a separate electrical connector through a flexible rope. The second supporting component comprises a horizontally disposed guide sleeve, the pull-out linkage component comprises a screw and a screw sleeve hand wheel, the screw is arranged in the guide sleeve, one end of the screw is connected with the dynamometer box, the other end is connected to the screw sleeve hand wheel, the screw sleeve hand wheel and the guide sleeve are connected through a circumferential mortise, and the screw sleeve hand wheel is rotated such that the screw drives the dynamometer box to move horizontally until the electrical connector is separated to be disconnected. At this time, the dynamometer displays a separation force value of a separation plug, the operation is easy, the device is safe and reliable, and the test precision is high.

Owner:雷义

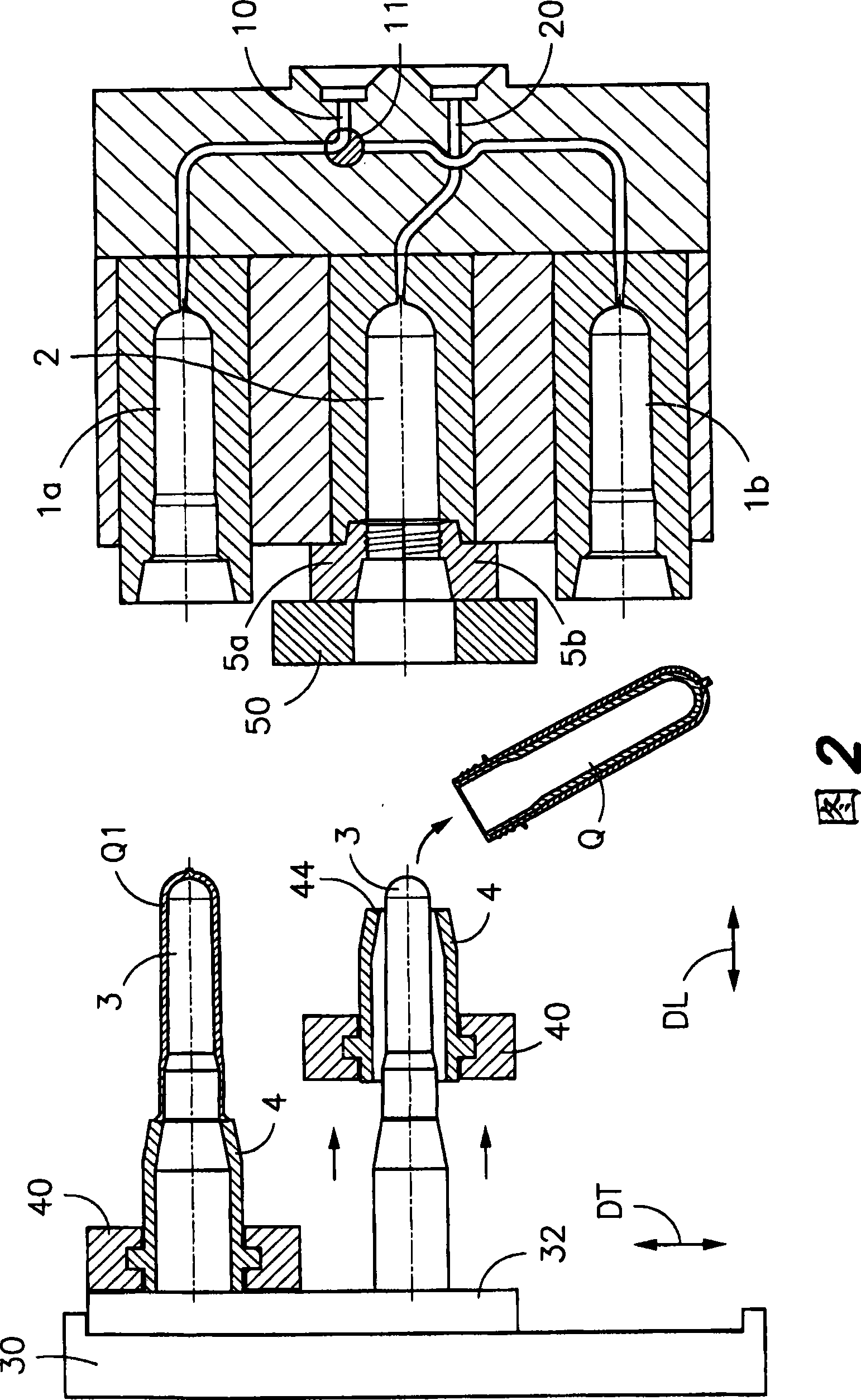

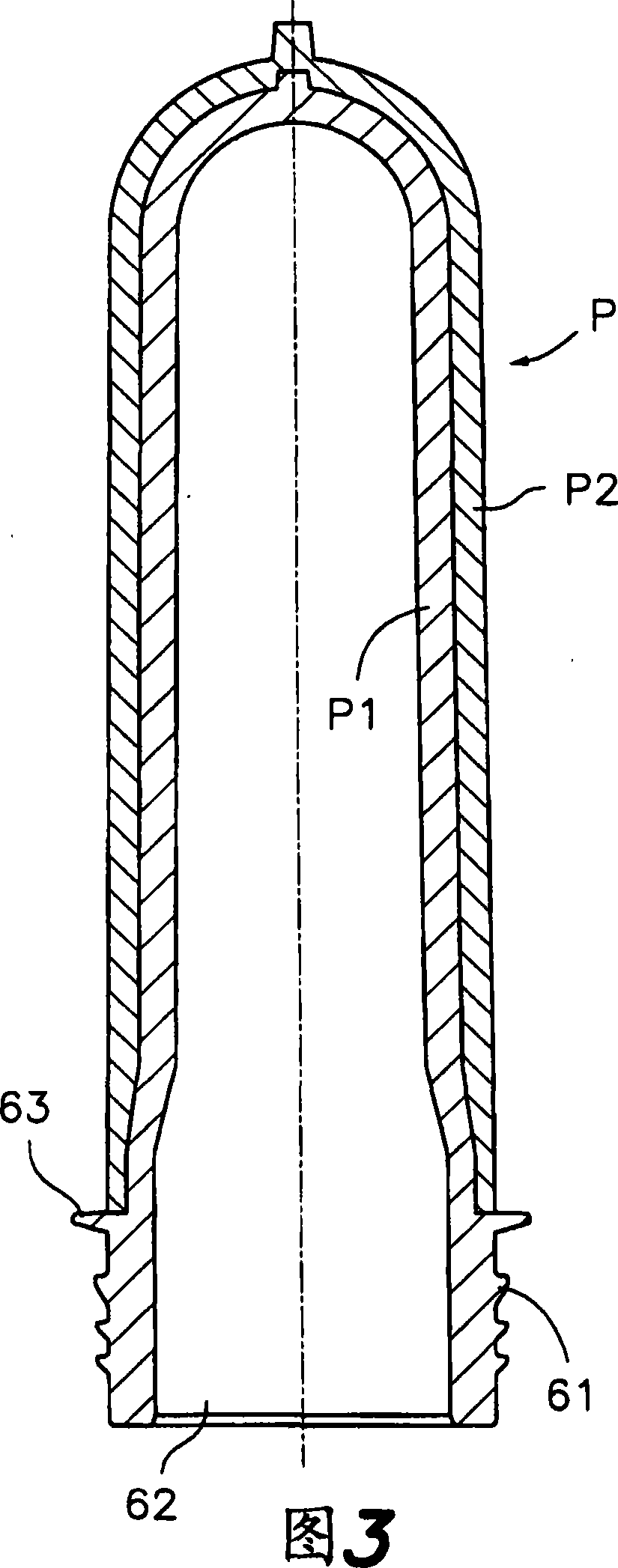

Apparatus and method for the production of bimaterial hollow bodies by means of injection overmoulding

InactiveCN101400496AEliminate the risk of damageImprove productivityDomestic articlesEngineeringInjection moulding

Owner:IND DE MOLDES Y MATRICES

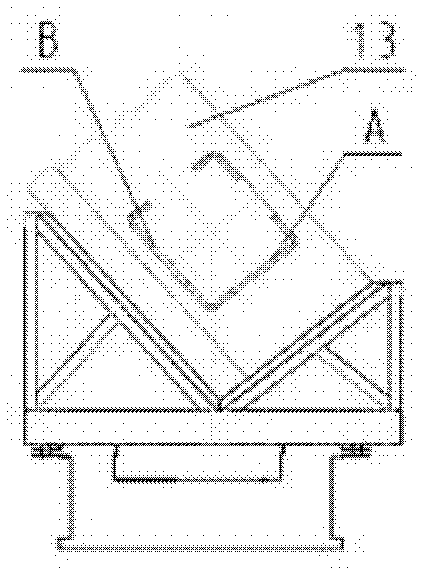

Flat plate type pathological toaster and water-draining device thereof

InactiveCN106840809AEliminate the risk of damageShorten production timeDrying solid materials without heatPreparing sample for investigationEngineeringParaffin section

The invention discloses a draining device for a flat-plate pathological roasting machine. The draining device includes a V-shaped bracket, a wedge-shaped support base and absorbent cotton. The absorbent cotton is laid on the V-shaped bracket, and the V-shaped bracket is fixed on the V-shaped bracket. on the wedge-shaped support base; the present invention also discloses a flat-plate roasting machine comprising the above-mentioned water-absorbing device, including a roasting table, the forward inclination angle of one side of the V-shaped support of the draining device is adjustable, and The front plate of the film stage is tightly combined. The flat-plate pathological roasting machine and the draining device thereof disclosed by the invention can quickly eliminate the water film between the paraffin tissue section and the glass slide, thereby preventing the expansion and displacement of the paraffin tissue section.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV +1

Optical fiber bundle fusion packaging device and packaging method

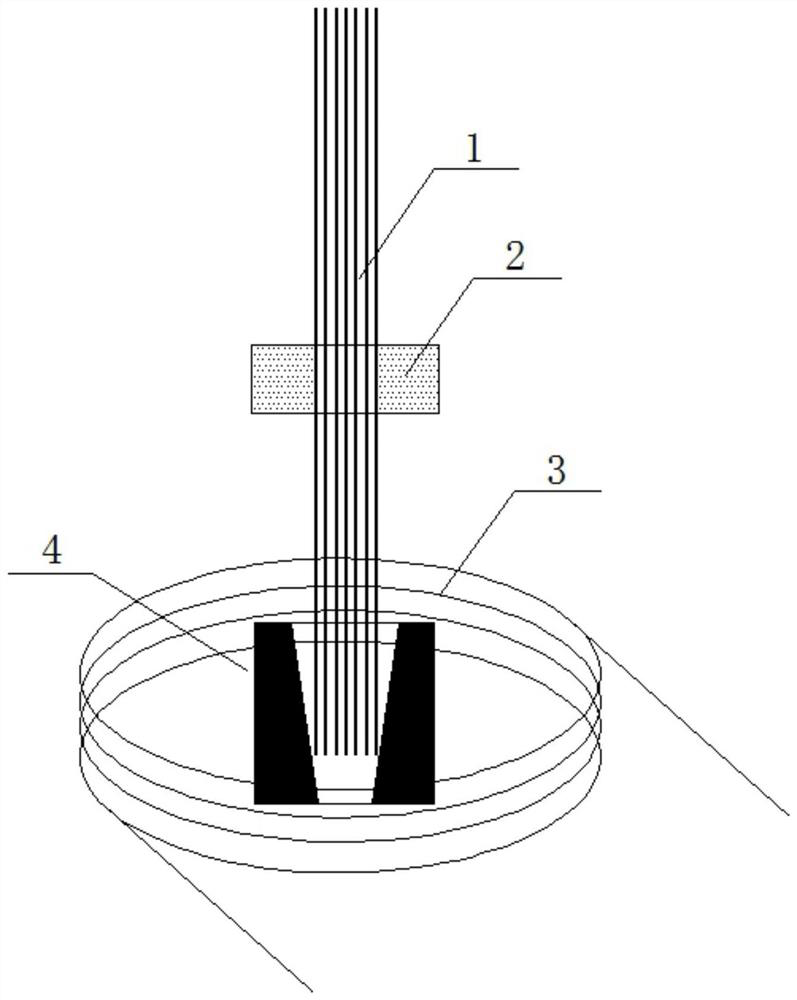

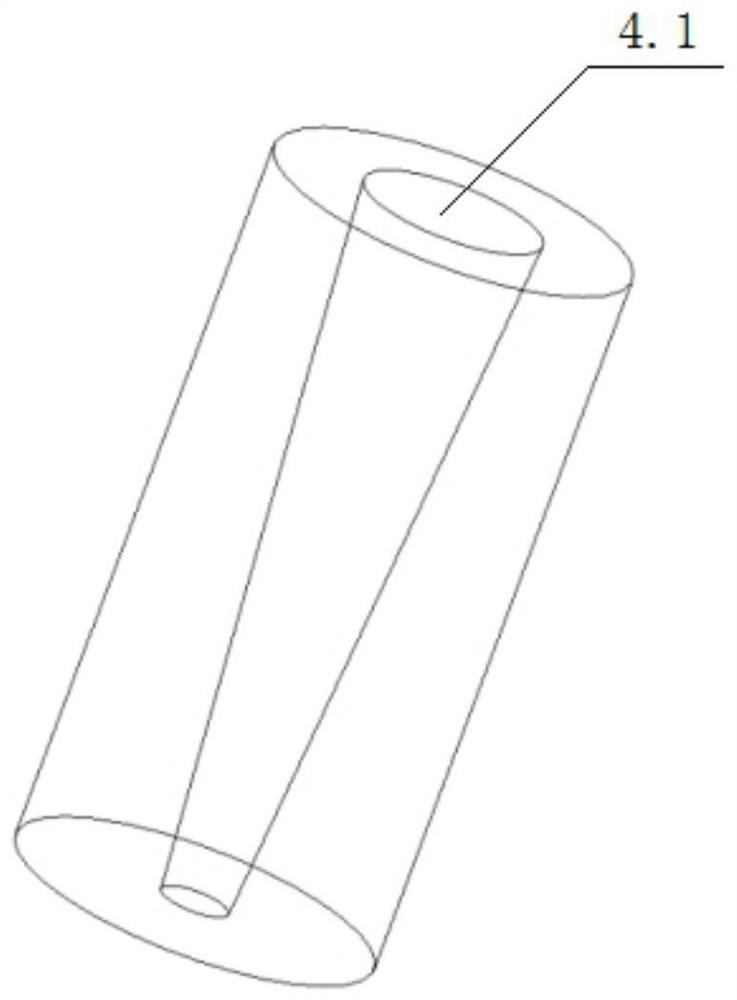

PendingCN112649917ASave packing timeImprove packaging efficiencyBundled fibre light guideElectrical and Electronics engineeringOptical fiber bundle

The invention relates to an optical fiber bundle fusion packaging device and packaging method, and belongs to the technical field of optical fiber packaging. The device comprises a lateral pressurizing mold, and the lateral pressurizing mold is arranged in an inner cavity of high-frequency induction heating equipment, so that an induction coil of the high-frequency induction heating equipment surrounds the lateral pressurizing mold. An optical fiber bundle is movably arranged in the lateral pressurizing mold in a penetrating mode and can vertically move along the lateral pressurizing mold. The high-frequency induction heating equipment heats the lateral pressurizing mold, so that the bare fiber section of the optical fiber bundle in the lateral pressurizing mold is softened, then circumferential pressure is applied to the softened bare fiber section of the optical fiber bundle through the lateral pressurizing mold, and fusion packaging of the optical fiber bundle is realized. According to the invention, the operation is convenient, the optical fiber bundle packaging time is shortened, the optical fiber bundle packaging efficiency is improved, and the production cost is reduced. After hot melting, the optical fiber bundle is a homogeneous whole, there is no heterostructure in the optical fiber bundle, and the risk of optical fiber damage caused by thermal stress is avoided.

Owner:JIANGSU FASTEN OPTOELECTRONICS TECH

Inclined foliage beating machine

InactiveCN100422436CIncrease chance of contactEliminate chasing phenomenonPulp beating methodsPulp and paper industrySlurry

The invention provides an incline-blade beater, wherein, the material cylinder is arranged on the base; the blades of material cylinder are 45 degrees inclined with the horizontal plane; when beating, the slurry material are impacted by the blades vertically and horizontally, to improve the contact percentage of slurry particles and the blades, eliminate the following hit condition between them, shorten the beating time, and eliminate the over-heat condition.

Owner:梁伟

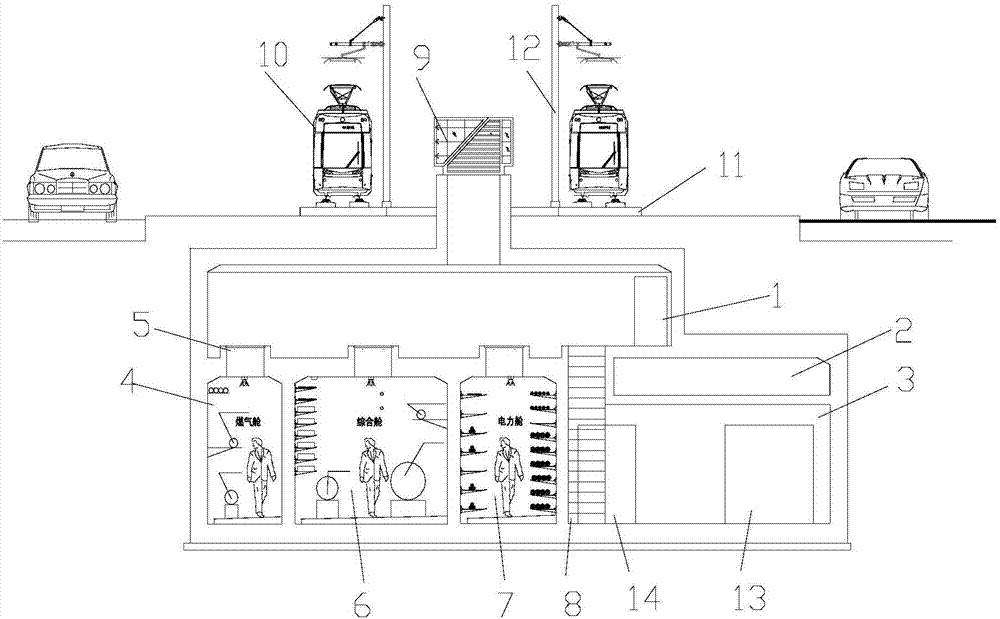

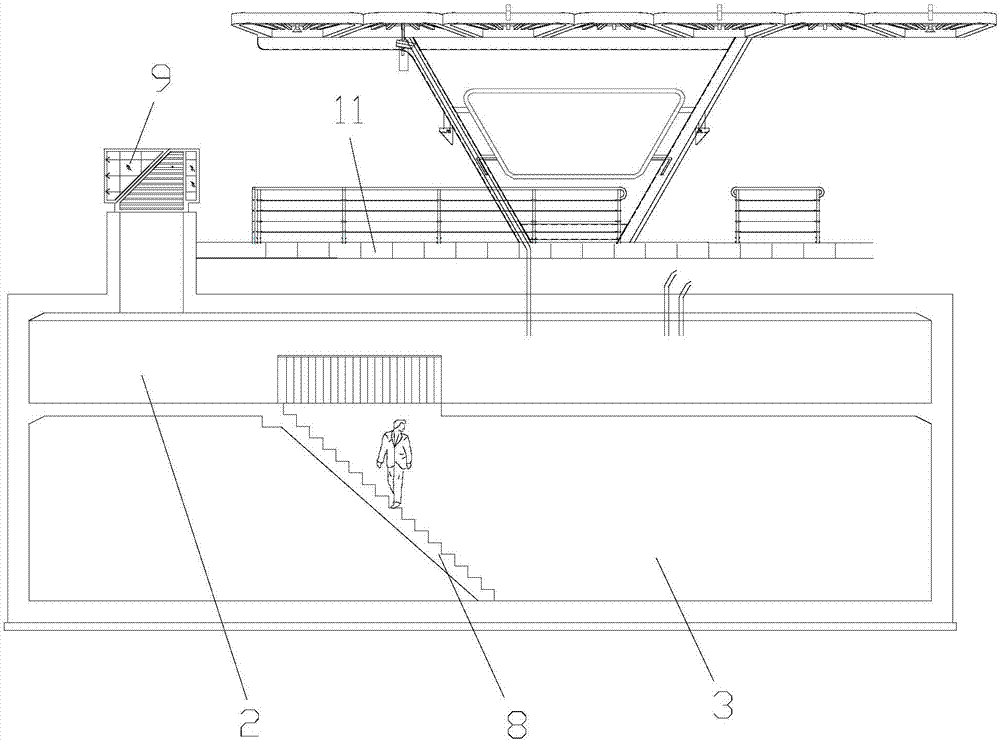

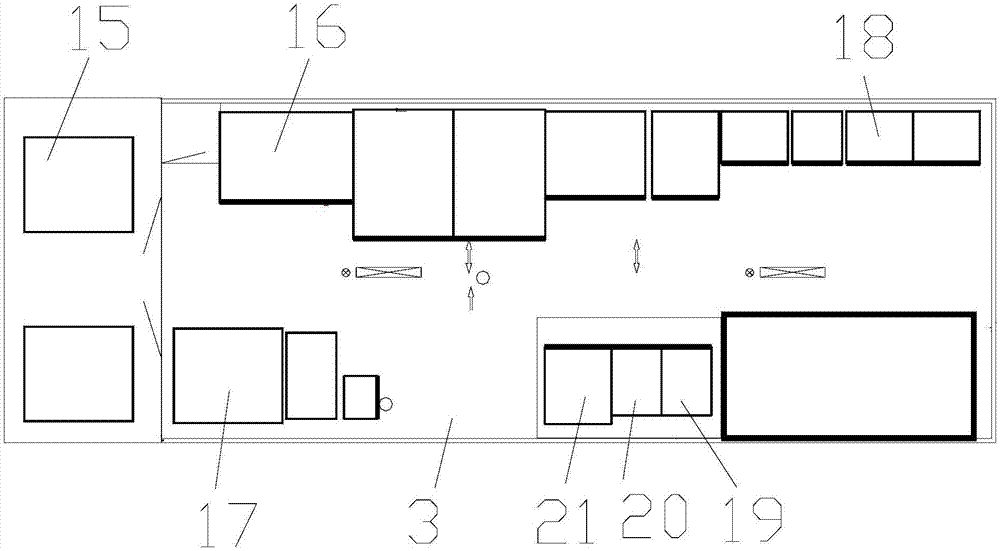

Comprehensive pipe gallery system integrated with power transformation, power supply and communication facilities of tramcar

PendingCN107964981AMeet the layout and applicationEasy to maintainArtificial islandsUnderwater structuresFirefightingCarriageway

The invention relates to the technical field of tram construction, in particular to a comprehensive pipe gallery system integrating tram transformation, power supply and communication facilities. It includes a tram station and an extended integrated pipe profile. The tram station includes two lanes of trams. The inner side of the lanes is equipped with a power supply line network, and the middle of the two lanes is equipped with feeding ventilation and personnel Wells and personnel entrances and exits, a comprehensive cabin and a power cabin are set on one side of the comprehensive pipe profile, and a main line substation is set on the other side, and a cable layered area is set above the main line substation, and the comprehensive pipe profile The access to the substation is set inside, and the access to the substation is connected to the feed ventilation and man well, and the entrance and exit of personnel, and the auxiliary facilities for drainage, fire protection, communication, video surveillance, and emergency lighting are set in the comprehensive pipe profile. It integrates the laying needs of power supply, communication, and gas along the line, and is convenient for maintenance. Considering the needs of traffic expansion, the comprehensive pipe gallery is reasonably arranged to save land and prevent equipment damage caused by water accumulation.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

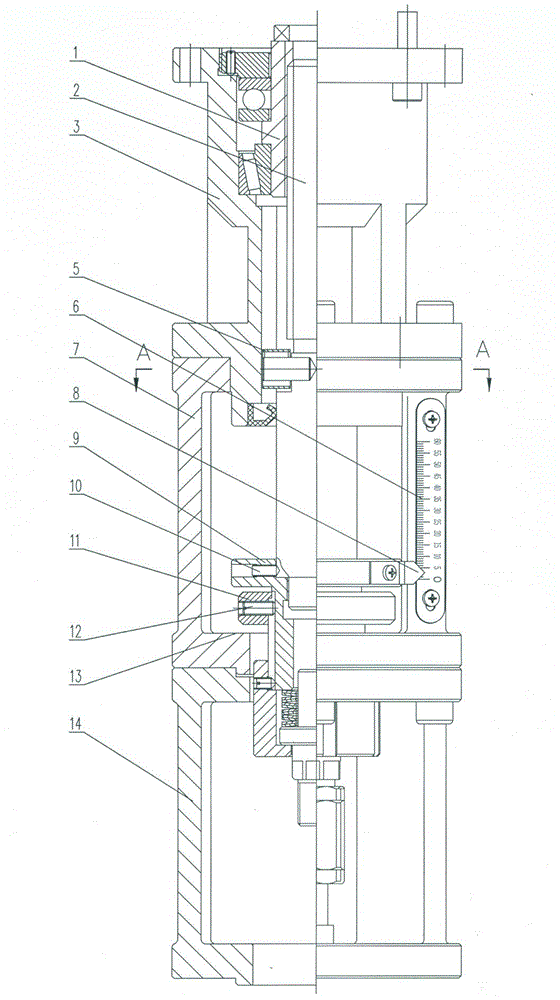

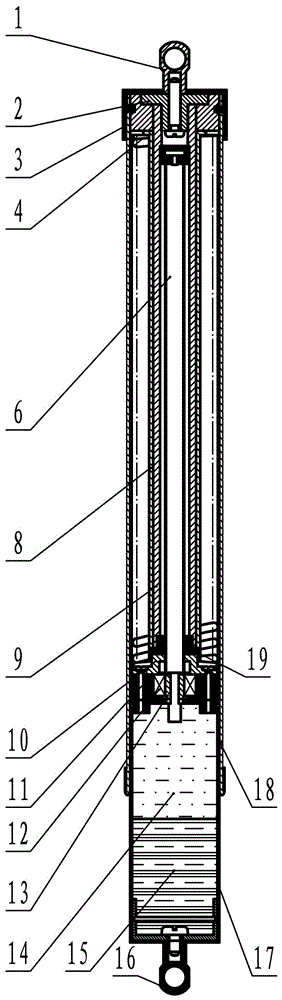

Straight stroke mechanism of multi-turn electric actuator

ActiveCN104653856AIntuitively see the displacementSee displacementOperating means/releasing devices for valvesEngineeringActuator

The invention discloses an improved invention of a straight stroke mechanism of a multi-turn electric actuator. The straight stroke mechanism comprises a bracket, a bearing seat, a screw and a nut, wherein the nut is matched with the screw, the bearing seat is installed on the bracket, the nut is connected with a main shaft of the multi-turn electric actuator, the screw is vertically arranged in the bearing seat and moves in a straight line up and down, and the lower end of the screw passes through the bracket and then is connected with a valve rod of a valve. The straight stroke mechanism is characterized in that a displacement display assembly which is used for displaying the displacement of the screw is arranged on the bracket, a limiting plane is formed on the inner surface of the bracket, a limiting nut which is matched with the limiting plane of the bracket and is used for controlling the displacement of the screw is installed on the screw, and internal threads of the limiting nut are matched with the screw. According to the straight stroke mechanism, the screw is mechanically limited, so that the valve rod is prevented from being excessively pulled up or being pressed, the safety performance is improved, and the service life of the valve is prolonged.

Owner:ZHEJIANG AOXIANG AUTO CONTROL TECH CO LTD

Raymond mill device with non-dust-accumulation draught fan

The invention discloses a Raymond mill device with a non-dust-accumulation draught fan. An air flow circulation abrasive powder discharge system is formed by the draught fan, a Raymond mill, a cyclone separation discharge device and an air return air pipe. A pressure equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe. A plurality of cyclones are arranged in the cyclone pipe. The lower end of the cyclone pipe is connected with a cyclone separator in the tangent direction. A lower pipe opening of the cyclone separator is soaked in a circulation pool which is connected with the upper end of the cyclone pipe. An impeller of the draught fan is of a structure that blades are in hollow reverse water drop shapes and a back plate is in a dish shape. The appearance contour line of the draught fan is an involute. According to the Raymond mill device, low-resistance pressure-equalized exhausting is achieved through the cyclone pipe and the cyclones, and therefore dust overflow caused by system positive pressure is eradicated. Wet-method efficient dust removal and mineral powder recycle are achieved through the circulation pool. By means of the structure that the blades are in the hollow reverse water drop shape and the back plate is in the dish shape, dust on the impeller of the induced draught fan is removed in real time, the strength of the impeller of the draught fan is improved, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and application prospects are wide.

Owner:JISHOU UNIVERSITY

Automobile air spring

InactiveCN107524365AEliminate the risk of damageHigh concentricityPower-operated mechanismAir springGas spring

The invention discloses an automobile gas spring, which comprises an upper outer tube with an upper ball head at one end and a lower outer tube with a lower ball head at one end, a motor is fixed inside the lower outer tube; the motor is connected with a screw rod through a gearbox, A fixed sleeve is provided between the screw rod and the gearbox; a screw nut is set on the screw rod, a screw sleeve is provided on the screw nut, and one end of the screw sleeve is connected with the upper ball head through the upper end cover; There is a conduit outside the screw sleeve, and the conduit is provided with a positioning part that abuts against the upper end cover; a spring is sleeved on the conduit; the fixed sleeve is embedded with the lower outer tube, and one end of the lower outer tube is embedded with the upper end cover. The outer wall of the lower outer tube near the end of the upper end cover is circumferentially distributed with a plurality of axial protrusions, and the inner wall of the upper outer tube is provided with a plurality of guide grooves which are circumferentially distributed and cooperate with the plurality of axial protrusions . Compared with the prior art, the present invention can solve the problem that the lower and upper outer tubes of the existing automobile gas spring are prone to rotation.

Owner:柳州劲胜科技有限公司

Pre-pressing clamp used for installing circuit board assembly in inertial integrated navigation equipment

ActiveCN111098251AAvoid local deformationEliminate the risk of damageWork holdersEngineeringPosition fixing

The invention provides a pre-pressing clamp used for installing a circuit board assembly in inertial integrated navigation equipment. A support assembly and a bottom plate located on the support assembly are fixedly connected into a whole through screws, and a pressing assembly used for pressing and fixing a printed board placed on a positioning area is arranged on the left side of the upper end face of the bottom plate; a positioning assembly is installed on the right side of the upper end face of the bottom plate, the position of the positioning assembly corresponds to the installation position of an integrated circuit on the printed board and the position of a convex face on a heat dissipation plate, and the bottom plate and the positioning assembly are leveled through a balance plate assembly; and the positioning assembly is provided with a heat conduction rubber pad, is located at the right side of the printed board and is fixed on the convex face on the heat dissipation plate onthe positioning area to tightly press the heat conduction rubber pad, and after the heat conduction rubber pad is deformed and stabilized, the heat conduction rubber pad, the heat dissipation plate and the printed board are bonded and fixedly connected. The pre-pressing clamp solves the defects existing in manual installation, the assembly consistency and the one-time assembly qualification rate are improved, the assembly height of the heat conduction rubber pad is controllable, the reliability of the installed circuit board assembly is high, and the application value is high.

Owner:SHAANXI BAOCHENG AVIATION INSTR

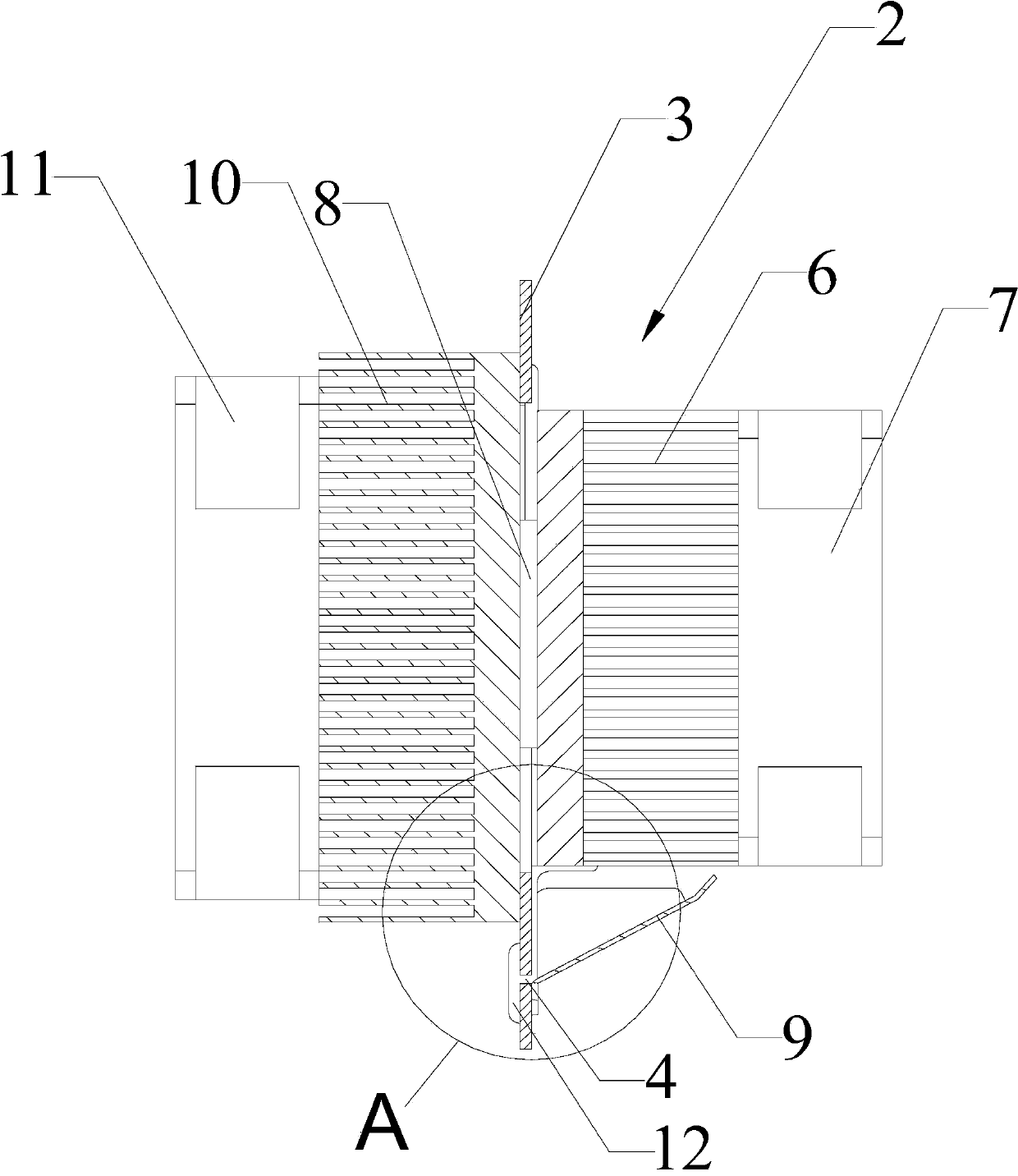

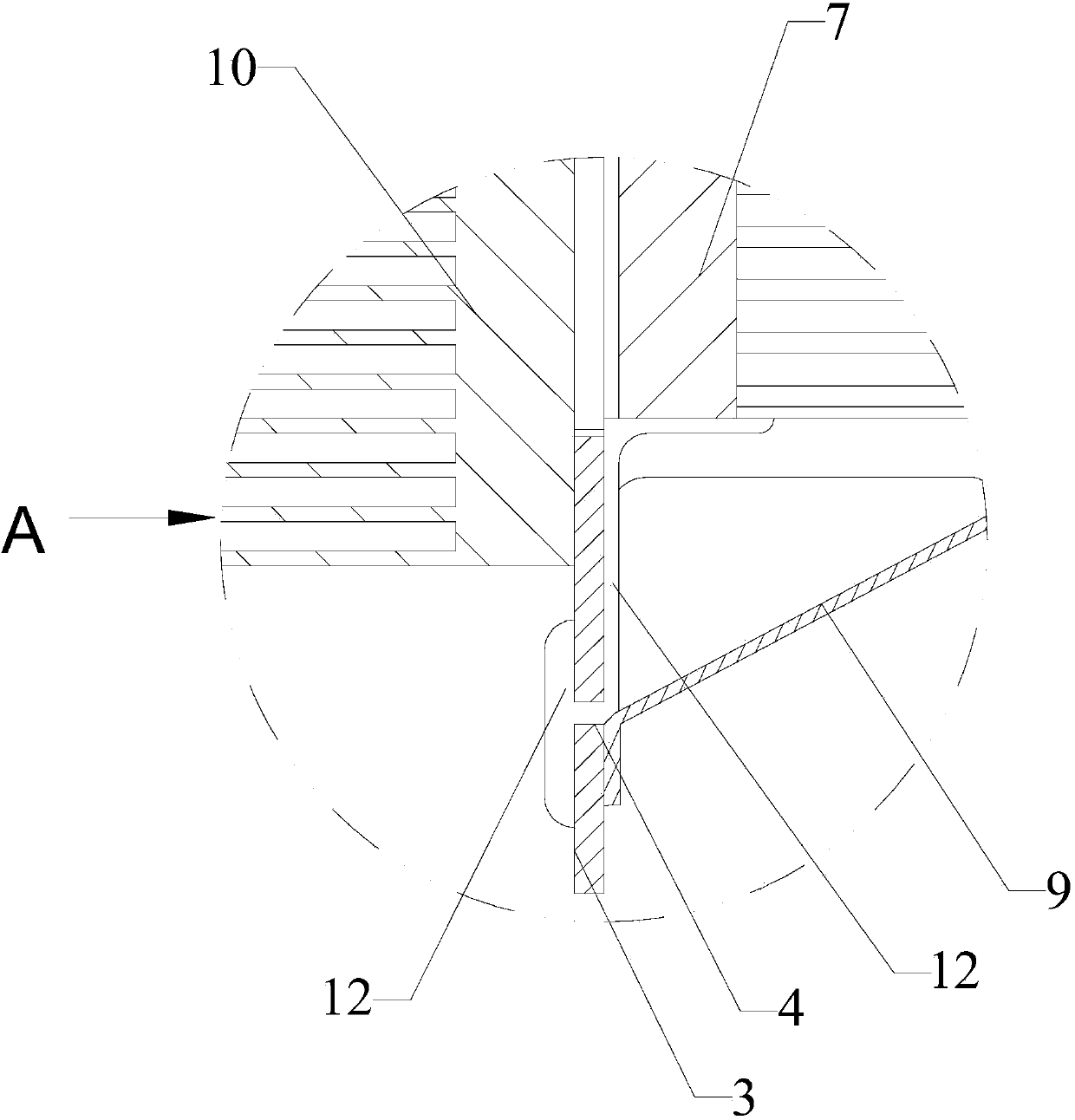

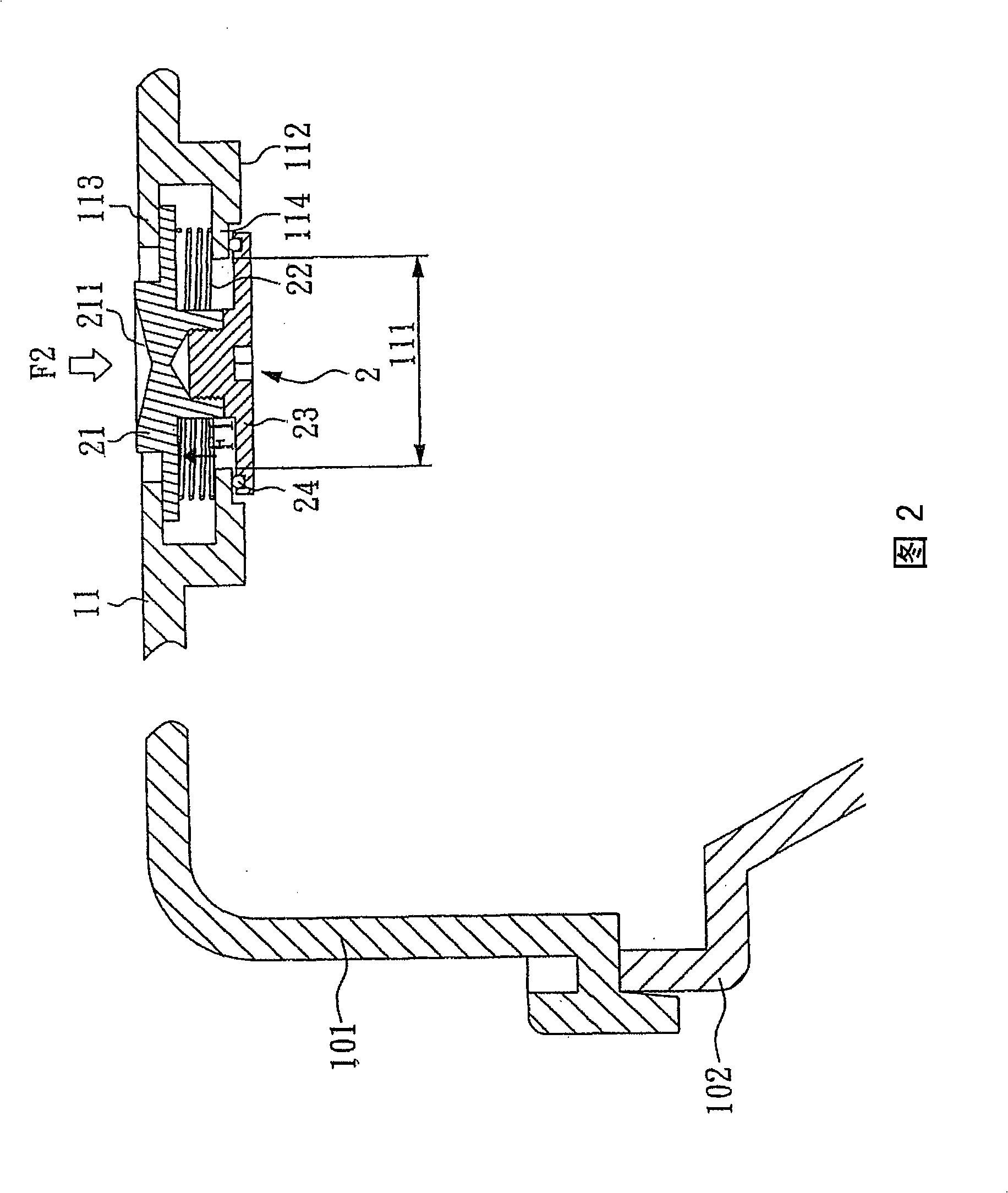

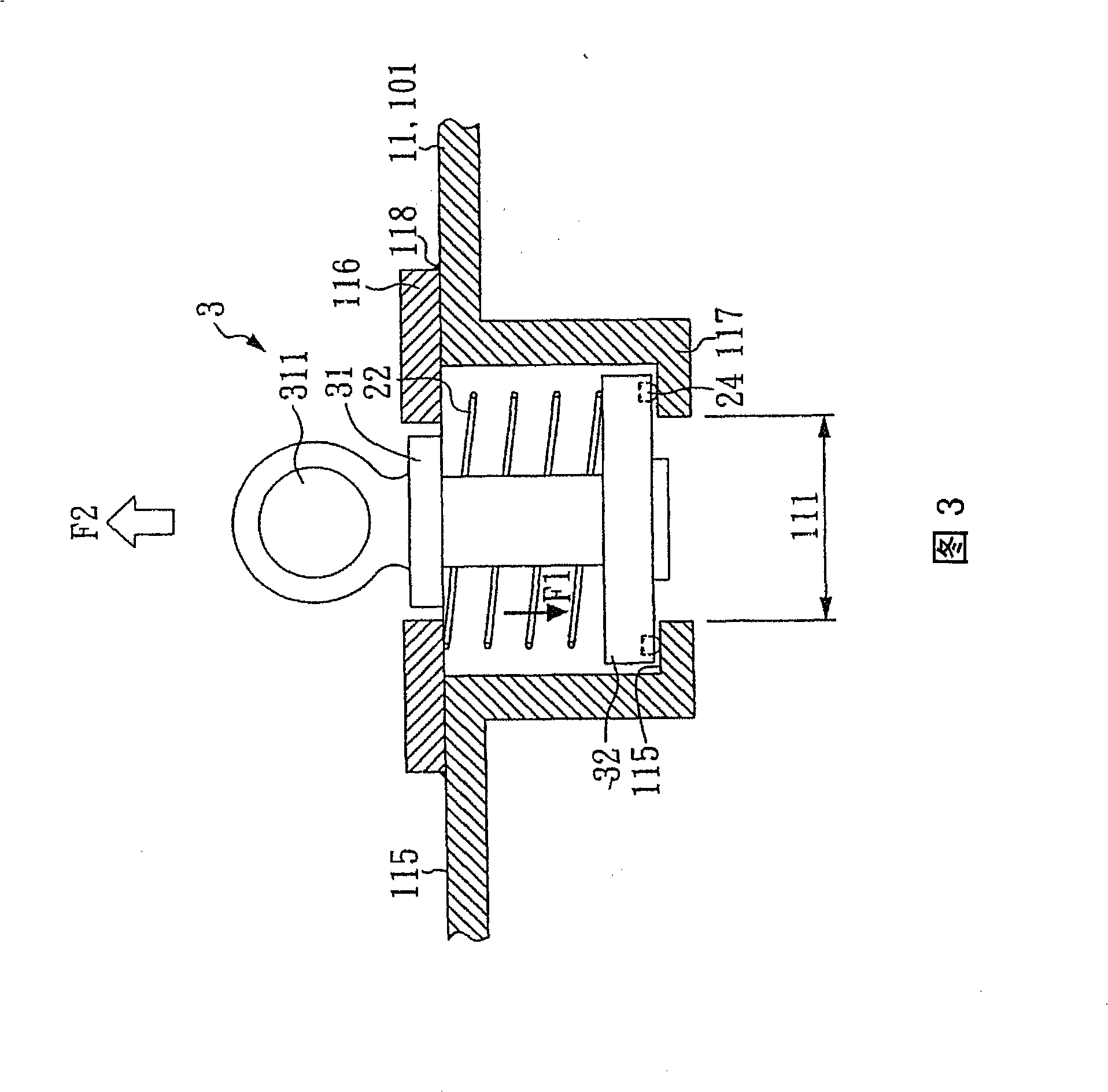

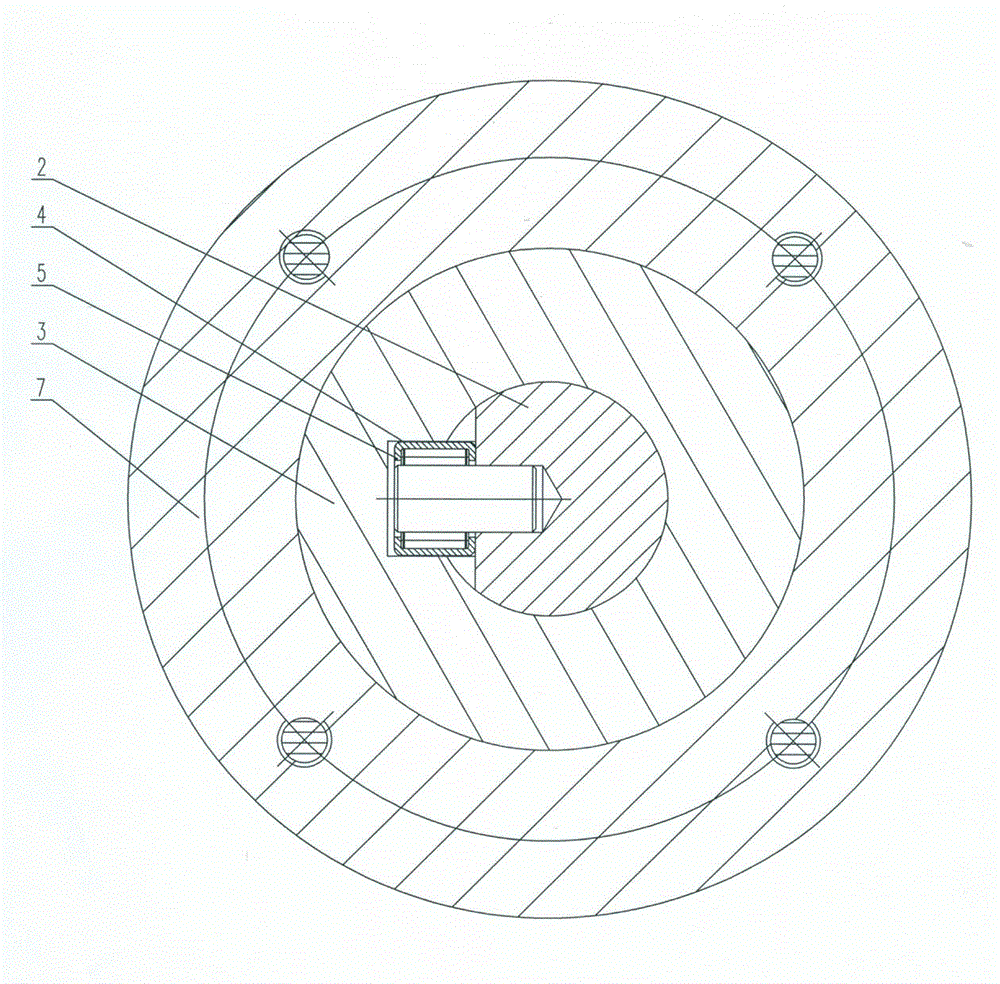

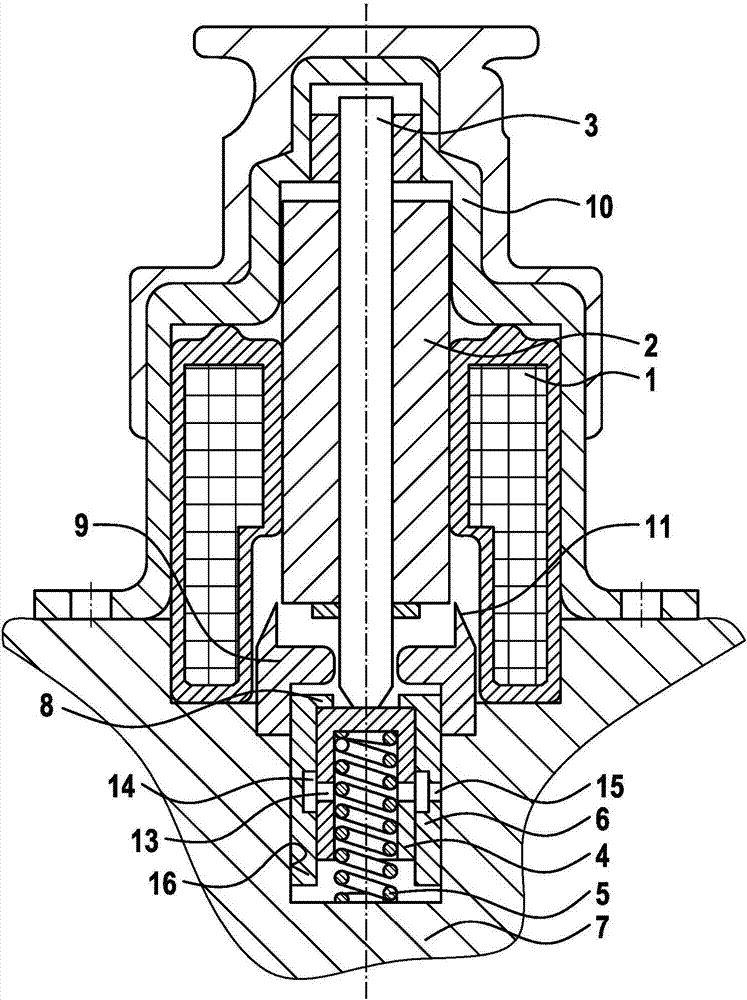

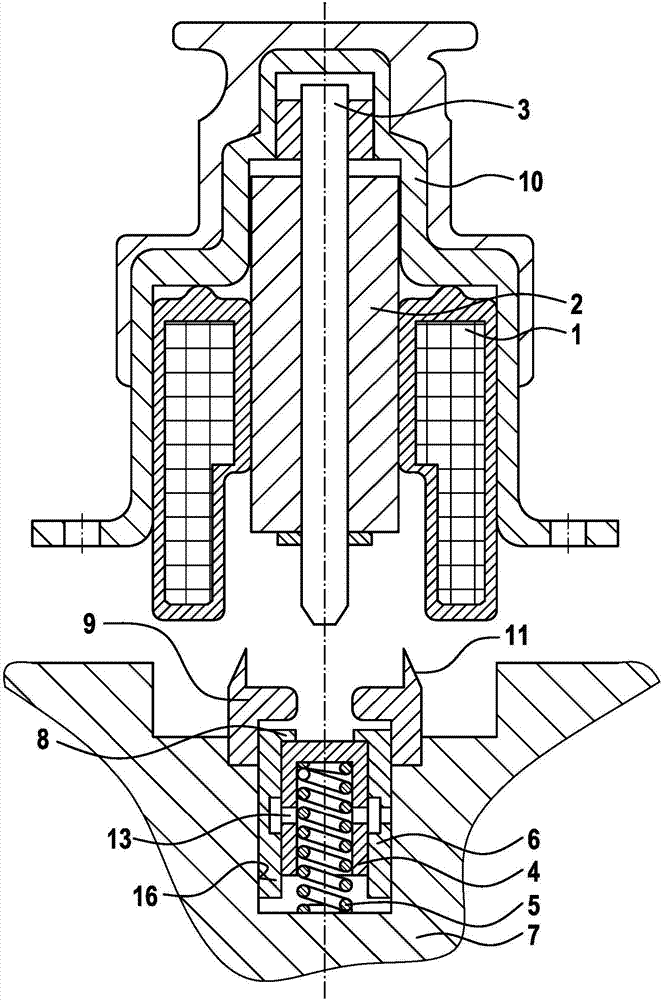

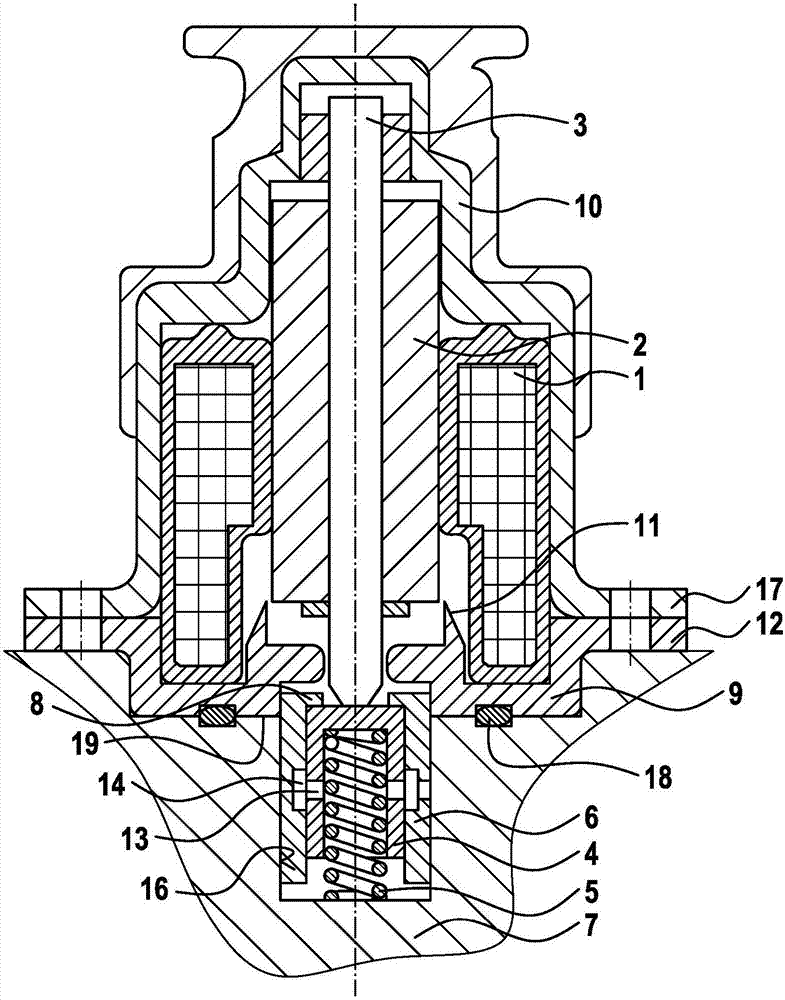

Proportional valve that can be electromagnetically actuated and high-pressure fuel pump having such a proportional valve

InactiveCN107110094AEasy to installEasy to shapeMachines/enginesFuel injecting pumpsReciprocating motionHigh pressure

The invention relates to a proportional valve that can be electromagnetically actuated for controlling the delivery rate of a high-pressure fuel pump, comprising an electromagnet (1) for acting on an armature (2) that can be moved in a reciprocating manner, wherein the armature (2) is coupled to an axially movable valve piston (4) by means of a tappet (3) such that the stroke of the armature (2) causes an axial movement of the valve piston (4) against the spring force of a spring (5). According to the invention, the axially movable valve piston (4) is accommodated in a flanged bush (6), by means of which the proportional valve can be connected to a housing part (7) of the high-pressure fuel pump. The invention further relates to a high-pressure fuel pump having such a proportional valve for controlling the delivery rate.

Owner:ROBERT BOSCH GMBH

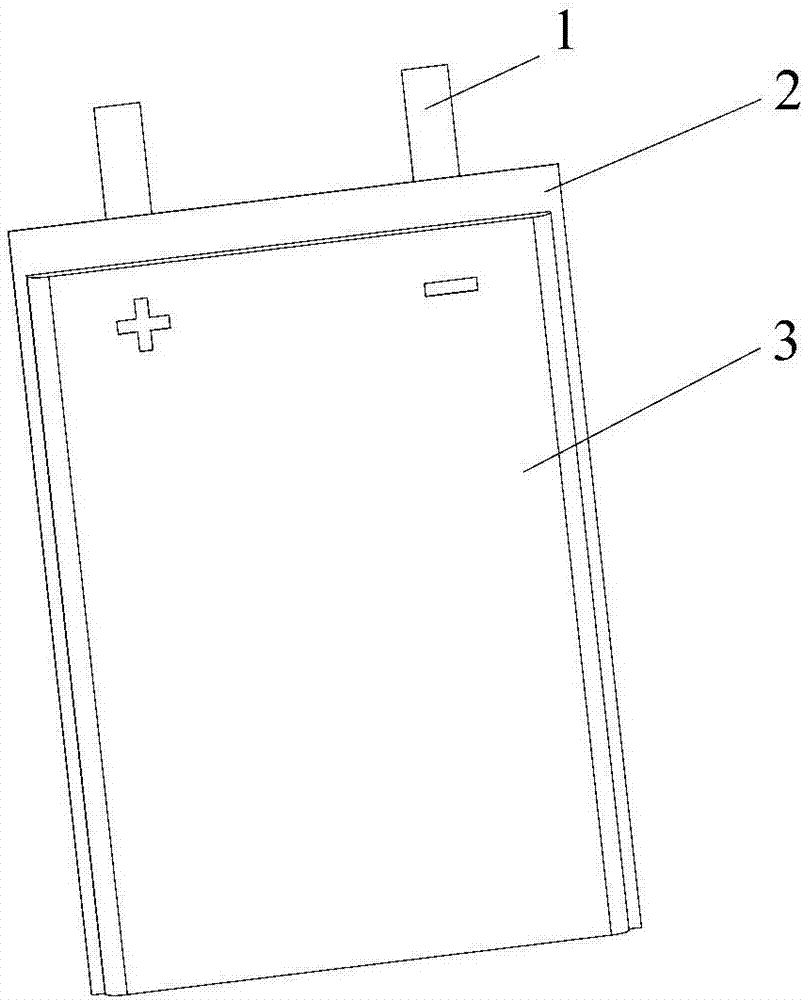

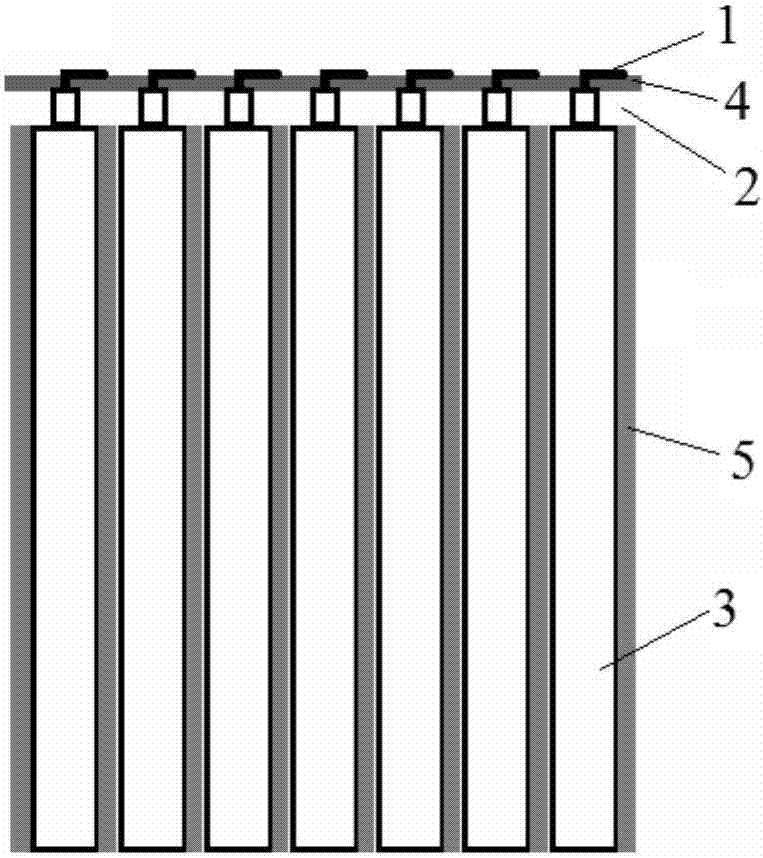

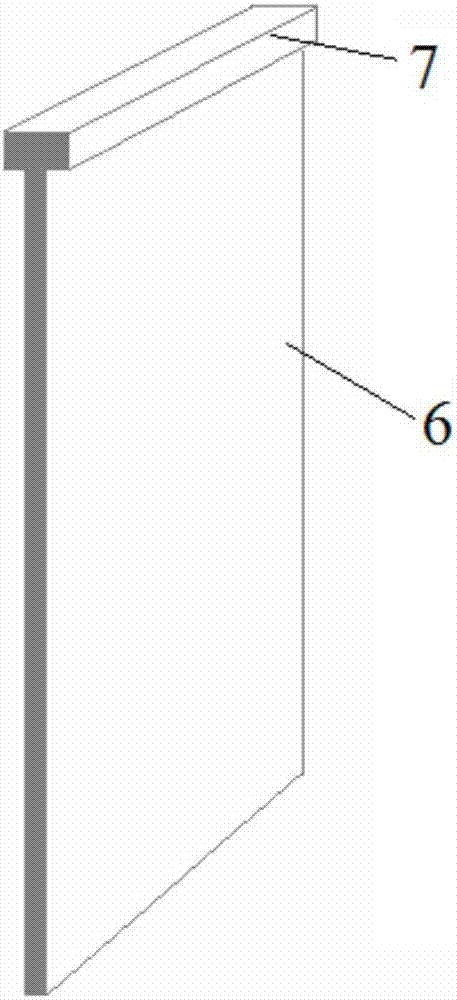

Separator plate, and flexibly packaged power battery having separator plate

PendingCN107170943AEliminate the risk of damageImprove securityCell seperators/membranes/diaphragms/spacersPower batteryBusbar

The invention discloses a separator plate. The separator plate comprises a separator plate body used for being arranged between the cell main bodies of two adjacent monomer cells of a flexibly packaged power battery, and a filling part connected with the separator plate body and used for being embedded into a gap between every cell main body and a busbar. The separator plate is provided with the filling part which is embedded into the gap between every cell main body and the busbar, so when a mechanical action force parallel to the direction of a tab is applied to the cells, the mechanical action force can be borne by the separator plate, thereby hidden destroy troubles of the tab, caused by the mechanical action force, are eliminated, and the safety of a battery is improved; and the separator plate greatly increases a way for improving the heat conduction efficiency, and improves the heat performances of the battery. The invention also discloses the flexibly packaged power battery.

Owner:江西优特汽车技术有限公司

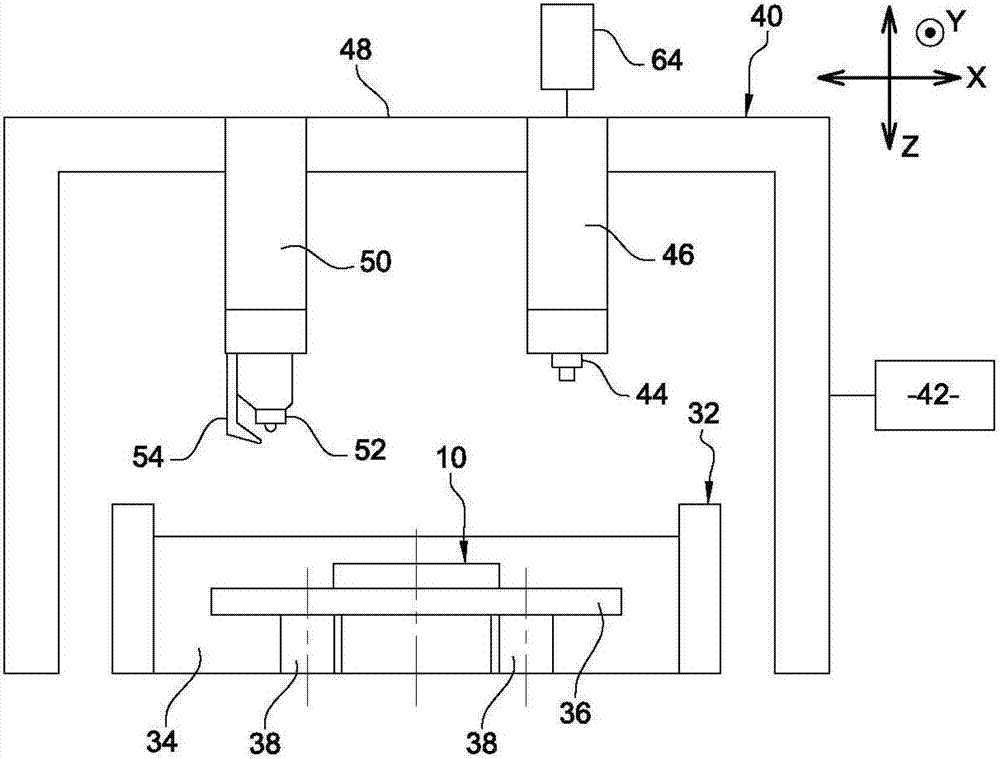

Electrode and facility for chamfering the corners of a metal workpiece

ActiveCN103079738AEliminate the risk of damageElectrochemical machining apparatusEngineeringElectrical and Electronics engineering

The invention relates to an electrode for chamfering the corners of a workpiece by electrochemical machining, comprising at least one conductive region (62, 68) to be arranged facing a workpiece corner to be chamfered. Said electrode is characterized in that the conducting region (62, 68) has a shape complementary to that of the chamfered corner to be produced, and is arranged between a first part forming an insulating excessive thickness, and an insulating second part for positioning the conducting region such that it faces the corner to be chamfered.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

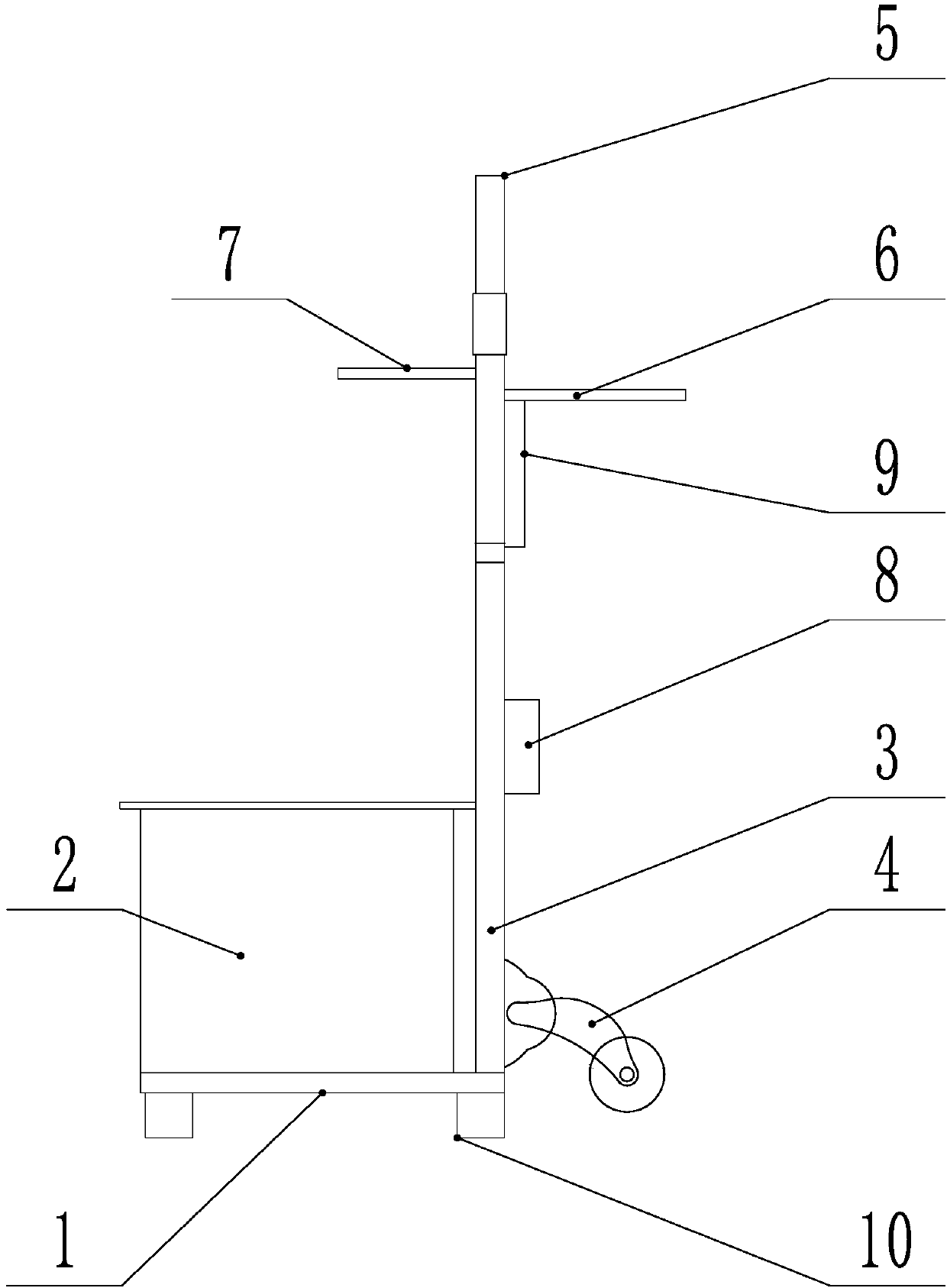

Multifunctional cart for carrying transformer-substation operation-and-maintenance rod tools

PendingCN107611830AReduce workloadReduce the intensity of handling workSwitchgearCartMultiple function

The invention discloses a multifunctional cart for carrying transformer-substation operation-and-maintenance rod tools, and relates to the field of transformer-substation operation and maintenance. When normal power cutting operation and power transmission operation are carried out, multiple operation tools are required to be carried many times. The multifunctional cart comprises a bottom plate, avertical support, a storage box, two trundles and a handle; an operation order folder is arranged on the right side of the middle of the support; an overturning-plate-type operation order platform isarranged on the right side of the upper portion of the support; an insulating-rod electroscope placing platform for placing insulating rods and electroscopes is arranged on the left side of the upperportion of the support; each trundle is of a single-rolling-wheel structure, and is fixedly connected to the right side of the lower portion of the support; a placing box of the operation order platform is arranged at the portion, located below the operation order platform, of the right side of the support, and a limiting structure for horizontal limiting of the operation order platform is arranged between the top of the placing box and the operation order platform. According to the technical scheme, carrying workloads are reduced, carrying working strength is reduced, operation-and-maintenance fault processing is more convenient accordingly, processing time is shortened, placing of tools is more normative, and the hidden danger of damage in the tool carrying and placing process is eliminated.

Owner:DAISHAN POWER SUPPLY CO STATE GRID ZHEJIANG ELECTRIC POWER CO +2

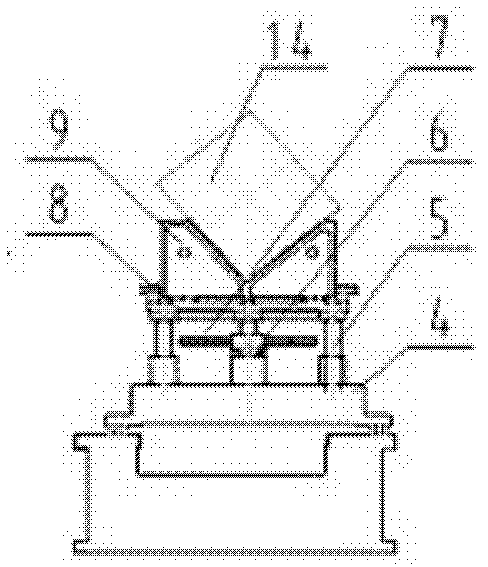

Assembling and scraping device for square hole of spindle box, assembling and scraping method and product assembling method

ActiveCN102501051AGuaranteed movement accuracyEliminate bruisesMetal working apparatusMaterial resourcesEngineering

The invention discloses an assembling and scraping device for a square hole of a spindle box. The assembling and scraping device is installed on a base lathe bed, a precision linear rail is arranged on the base lathe bed, the assembling and scraping device is provided with a spindle box body V-shaped support seat and a moving seat, and the spindle box body V-shaped support seat is fixedly installed on the base lathe bed; the moving seat is installed on the precision linear rail to form sliding fit, and a ram component V-shaped support seat is arranged on the moving seat; a ram support seat adjusting mechanism is arranged between the moving seat and the ram component V-shaped support seat; and a ram traction device is arranged on the base lathe body and is connected with a ram component through a cable. The invention also discloses an assembling and scraping method and a product assembling method of the device. With the technical scheme, the production efficiency is improved, the hidden danger that the ram component collides with the spindle box to impact or injury the workpiece is eliminated, the manufacturing precision of the product is increased, the product quality is greatly improved, and manpower and material resources are saved.

Owner:WUHU HENGSHENG HEAVY MACHINE TOOL

Cassette with air inlet valve

InactiveCN100573843CEliminate the risk of damageEasy to openClosuresSemiconductor/solid-state device manufacturingInlet valveEngineering

The invention relates to a crystal boat box with an air inlet valve, which includes a box body and an air inlet valve. The intake valve is arranged on the shell of the box body, which includes a guide post, a sealing cover, a sealing washer and an elastic component. The intake valve is provided with an elastic pre-force by the elastic component to push the guide post to cover the sealing cover on the through hole of the housing correspondingly, so that the sealing gasket is pressed between the sealing cover and the housing to form an airtight seal. Therefore, when you want to open a vacuum crystal boat box in a box, you only need to use an external force to reverse the deduction column, so that there is a gap between the sealing cover and the outer shell. The internal space of the box can balance the air pressure inside and outside the box, so that the box lid can be opened easily.

Owner:KING YUAN ELECTRONICS

Raymond mill system capable of preventing dust accumulation of fan

The invention discloses a Raymond mill system capable of preventing dust accumulation of a fan. The fan, a Raymond mill, a cyclone separating discharging device and an air return air pipe form an air circulating milling discharging system. A pressure equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe. A plurality of cyclones are arranged in the cyclone pipe. The lower end of the cyclone pipe is tangentially connected with a cyclone separator. A cyclone separating lower pipe opening is immersed in a circulating water pool, and the circulating water pool is connected with the upper end of the cyclone pipe. The fan impeller is provided with blades adopting a hollow and wedge-shaped structure. The external contour line of the fan is an involute. Low-resistance pressure equalizing exhaust is realized through arranging the cyclone pipe and the cyclones, and dust overflow caused by system positive pressure is eliminated. The circulating water pool realizes wet-process efficient dust removal and mineral powder recycling. As the blades adopt the hollow and wedge-shaped structure, dust on the induced draft fan impeller is cleared in real time, the impeller strength of the fan is increased, the stability is enhanced, and safety accidents caused by dust accumulation are effectively avoided. The application prospect is wide.

Owner:江苏铸友锆钛科技有限公司

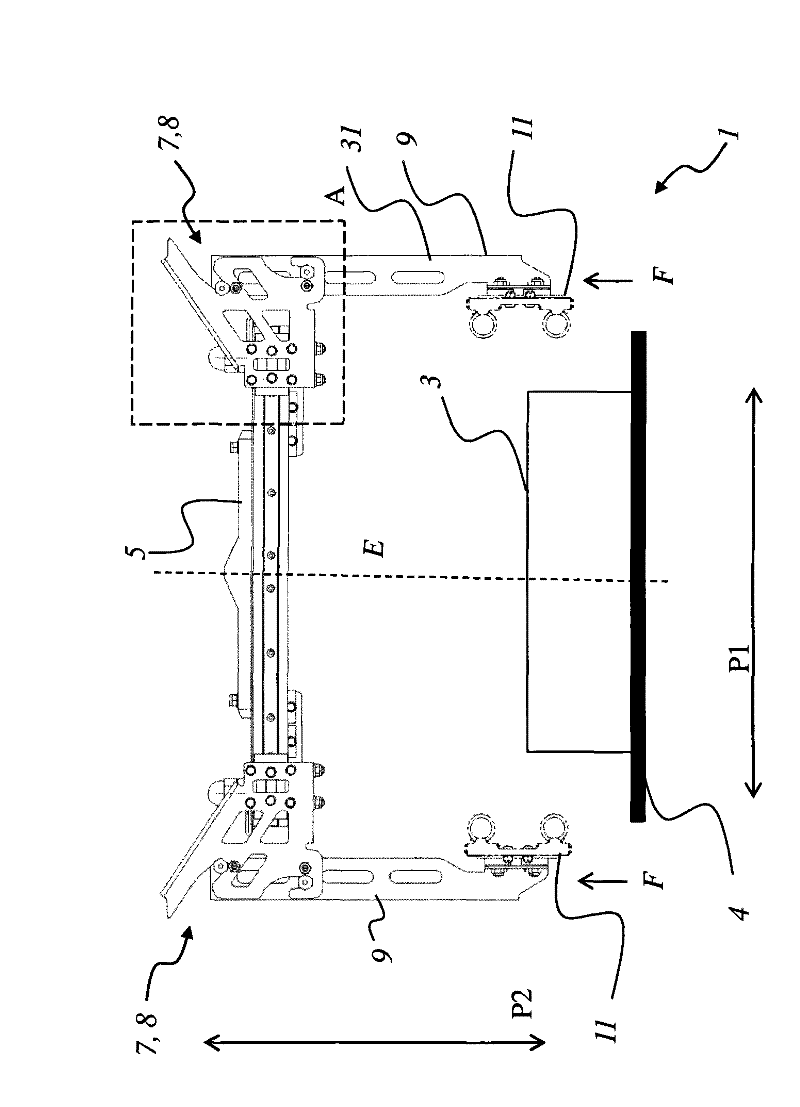

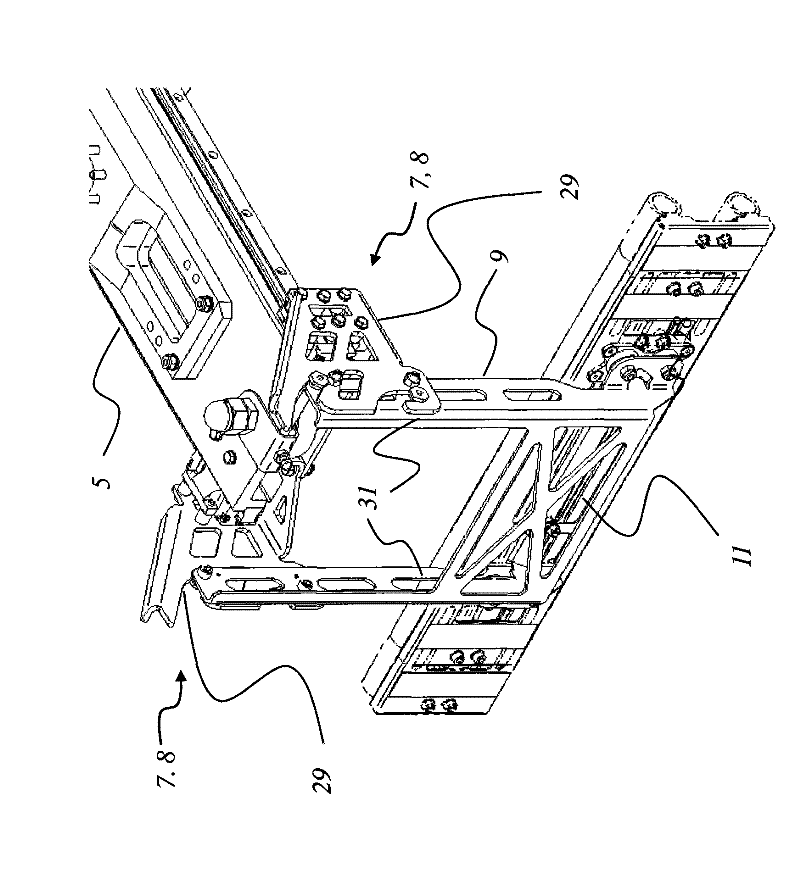

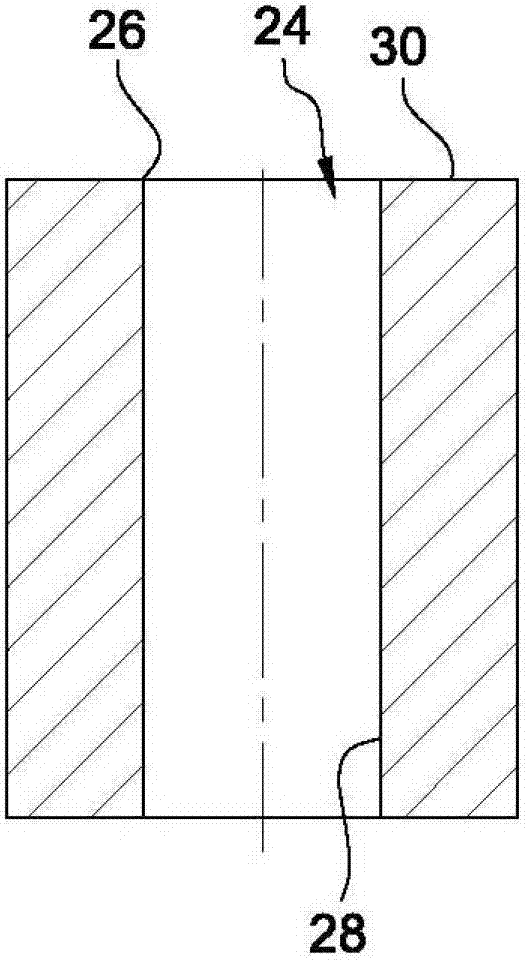

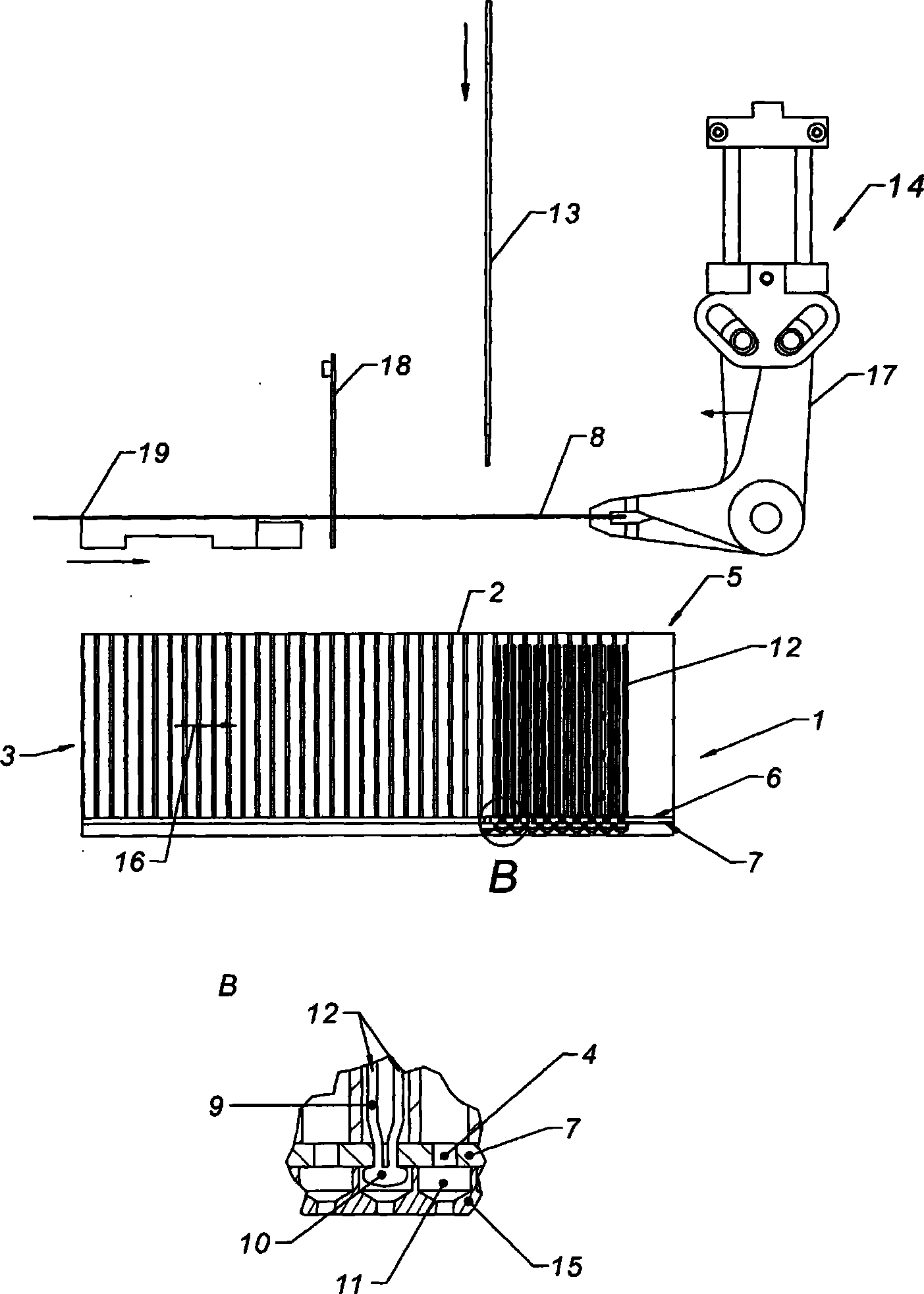

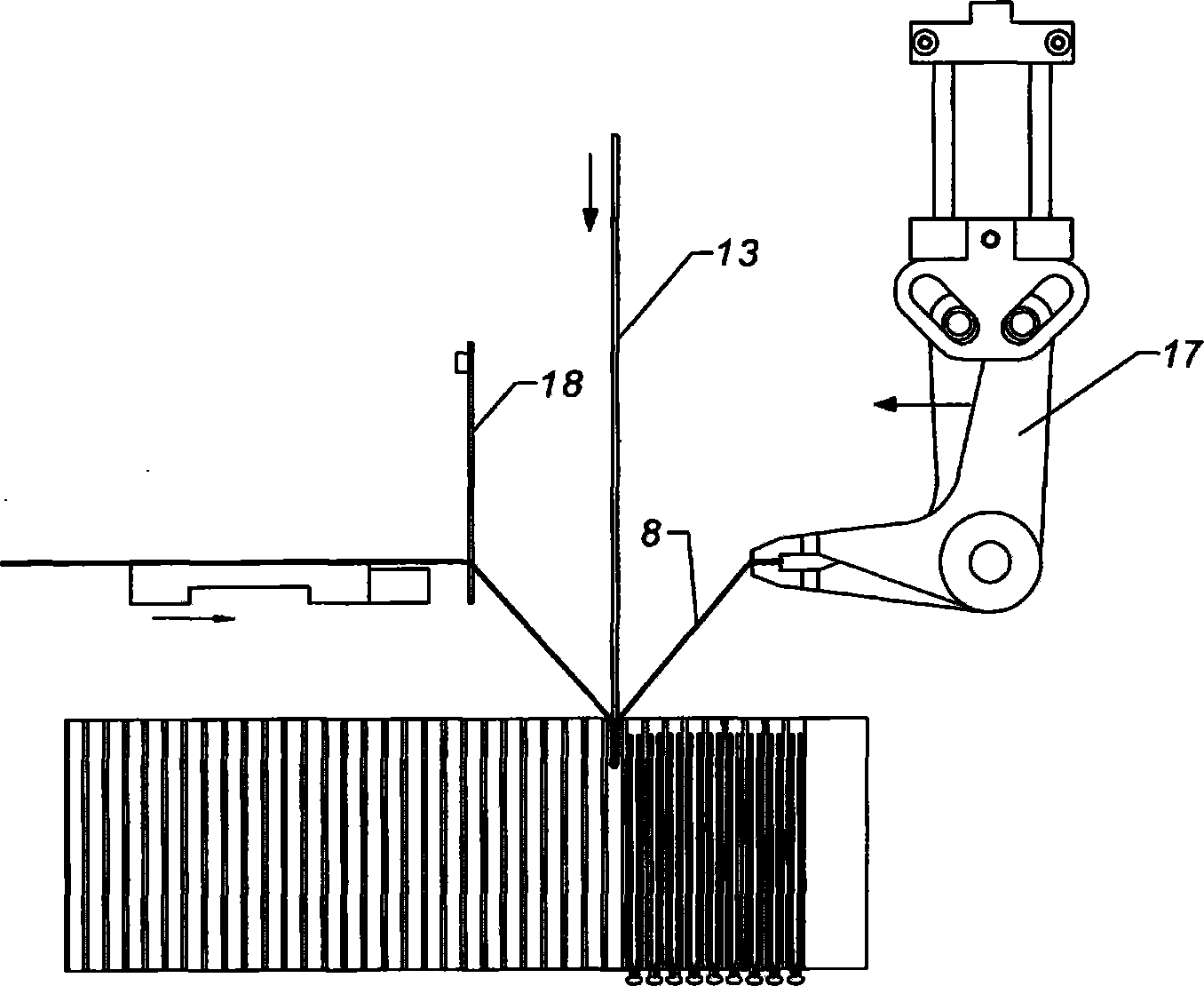

Method for manufacturing pile carpet

InactiveCN103797172AEliminate the risk of damageOptimize layoutTufting apparatusLayered productsYarnWaste management

The invention relates to a method for manufacturing pile carpet or pile carpet tiles, wherein a pile yarn (8) is connected via a pile thread holder (1) to at least a primary backing (7), wherein the pile thread holder (1) comprises a plurality of pile thread guide channels (2) which perforate the pile thread holder (1) through two opposite sides, wherein the pile thread holder (1) is provided between a pile thread gripping station (14) on a first perforated side (5) and a primary backing (7) on a second perforated side (6) such that the pile yarn (8) is arranged via the first perforated side (5) through a pile thread guide channel (2) to the second perforated side (6) onto, into or through the backing (7).

Owner:CTTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com