Raymond mill system capable of preventing dust accumulation of fan

A technology of Raymond mill and fan, applied in the field of Raymond mill system, can solve problems such as personnel and equipment safety accidents, strong vibration, etc., and achieve the effects of reliable use, high strength and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

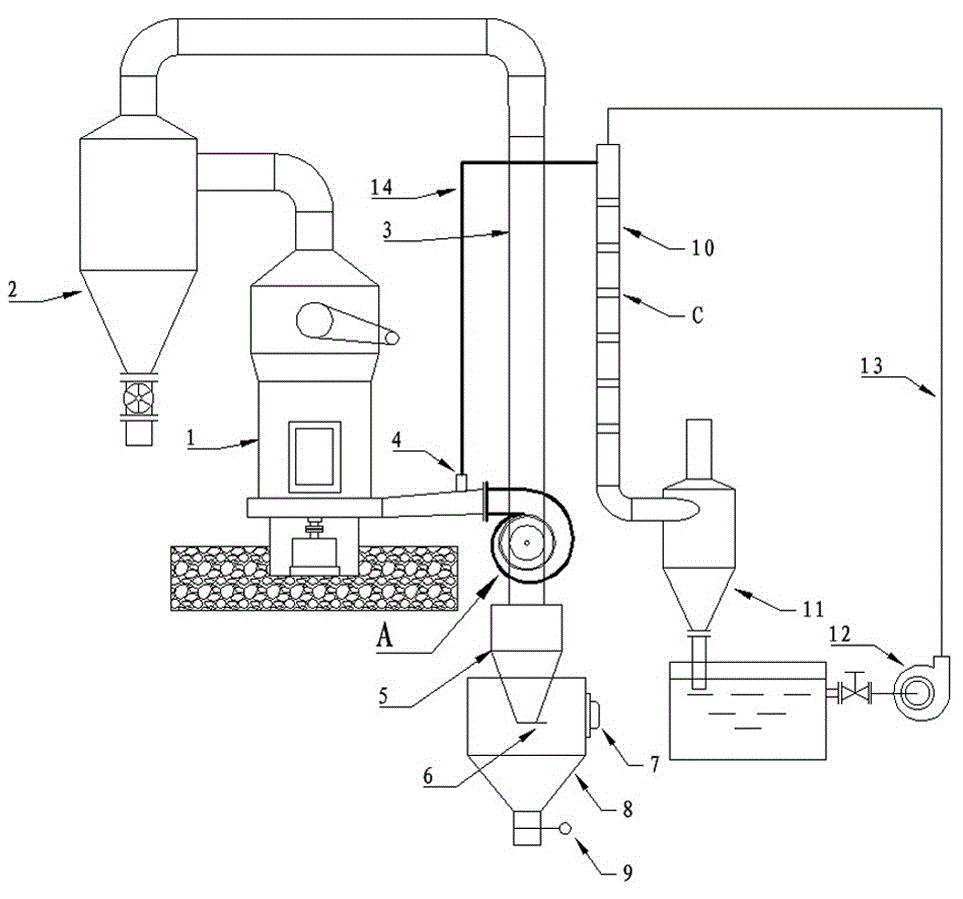

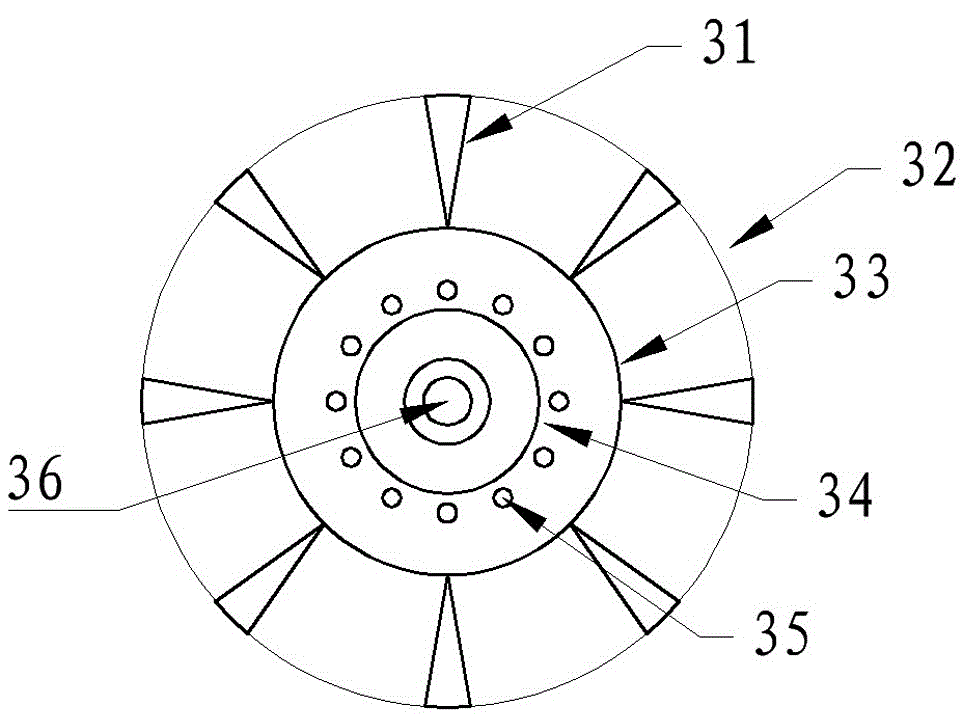

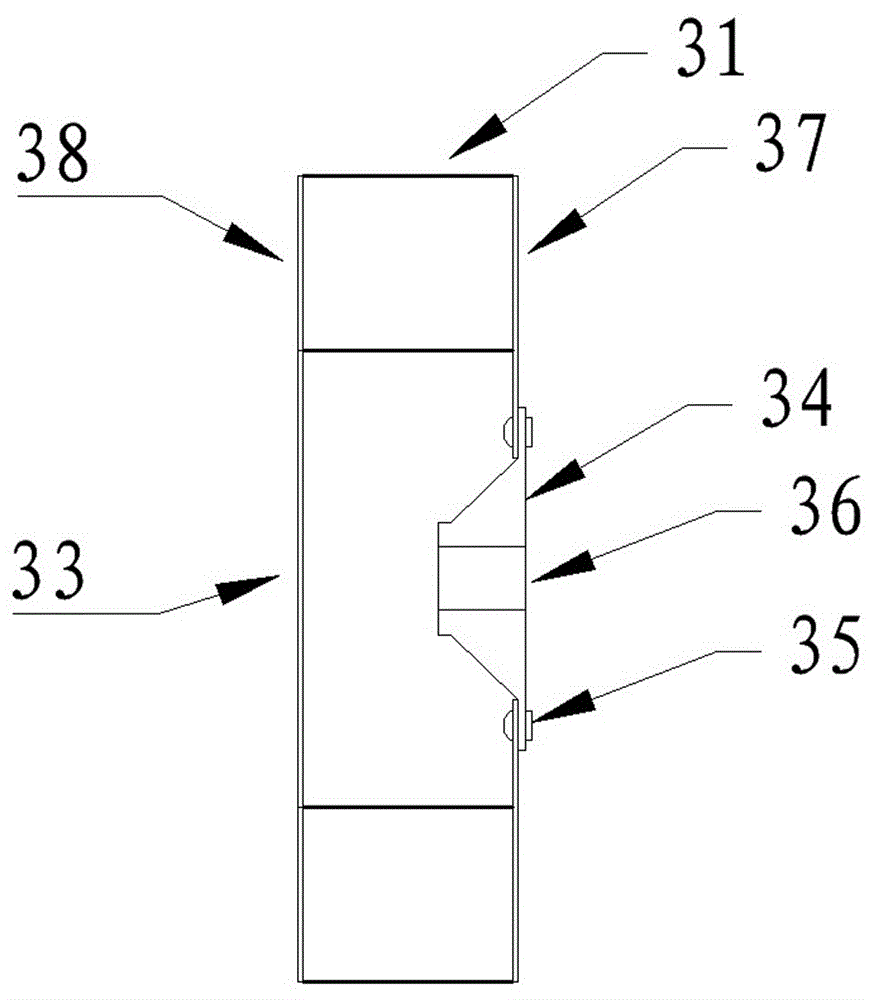

[0028] A. Fan; C. Cyclone; 1. Raymond mill; 2. Cyclone separation discharger; 3. Return air duct; 4. Pressure equalization exhaust branch pipe interface; 5. Isolation temporary storage barrel; 6. Gravity material Door; 7. Valve; 8. Temporary powder storage barrel; 9. Discharge gate; 10. Cyclone pipe; 11. Cyclone separator; 12. Circulating pump; 13. Circulating water pipe; 14. Equalizing exhaust branch pipe; 31 , wedge-shaped blade; 32, impeller outer circle; 33, impeller air inlet; 34, shaft seat; 35, rivet; 36, shaft hole; 37, impeller back plate; 38, impeller panel; 41, impeller; 42, casing inlet Air outlet; 43, involute circle; 44, machine base; 45, casing; 46, cover plate of air inlet of casing; 47, air outlet of casing; B, width of air outlet of casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com