Method for manufacturing pile carpet

A technology for pile and carpet, applied in the field of manufacturing pile carpet, device for implementing the method, V-shaped pile cut pile carpet block, pile carpet block field, can solve pile yarn damage, loss of base fabric, slow Production process and other problems, to achieve the effect of easy layout and elimination of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

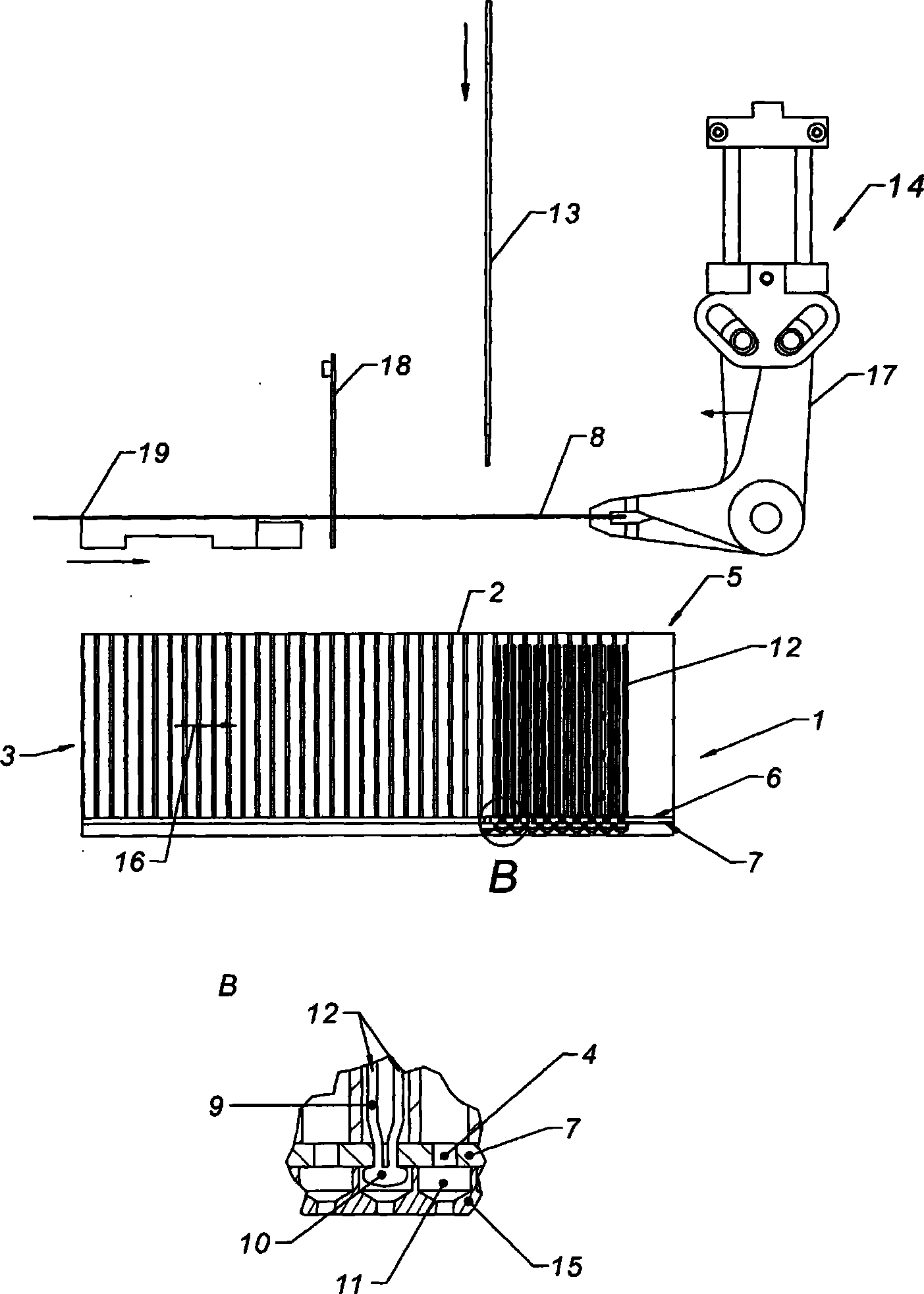

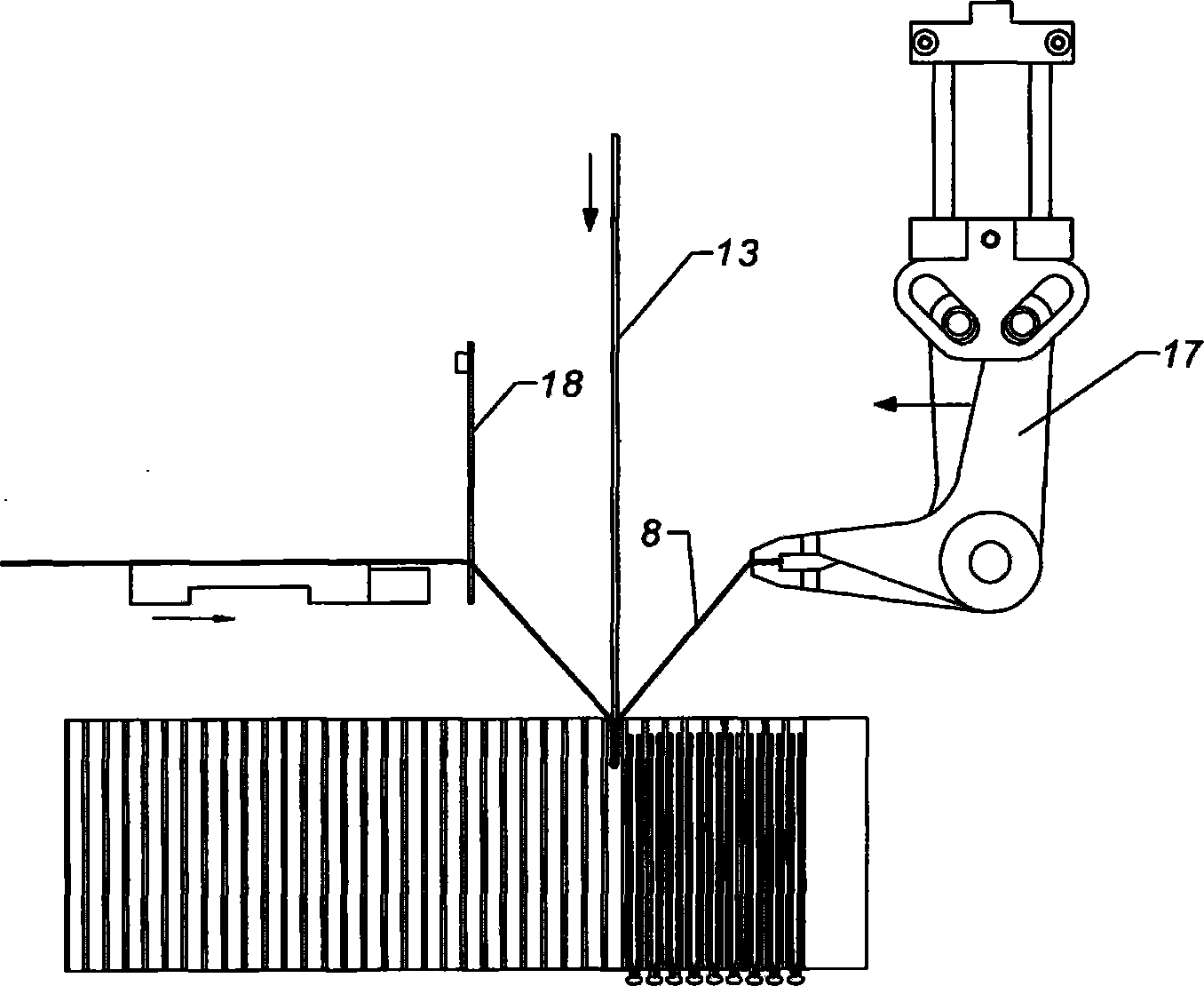

[0068] figure 1 and figure 2 shows an embodiment of a method and a device for manufacturing a carpet tile according to the invention, said device comprising a flat Pile thread holder 1.

[0069] The pile thread holder 1 is provided with a pile thread guide channel 2 which is perforated from one side 5 (of the clamping station 14) of the pile thread holder to the other side 6 (of the backing 7) . The two sides 5 and 6 of the pile thread holder are parallel and separated by a distance equal to the length of the pile thread guide channel 2 . The pile thread guide channel 2 is preferably positioned perpendicular to the perforated sides 5 and 6 of the pile thread holder. The pile thread guide channels 2 are preferably arranged in a matrix configuration on each side surface.

[0070] The advantage of such a construction is that the carpet tile will thus have no production direction, as is the case in classical techniques such as weaving and tufting. This therefore means that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com