Electrode and facility for chamfering the corners of a metal workpiece

A technology of metal components and components, applied in metal processing equipment, manufacturing tools, electrochemical processing equipment, etc., can solve the problems of time-consuming, unreliable testing, etc., and achieve the effect of eliminating the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

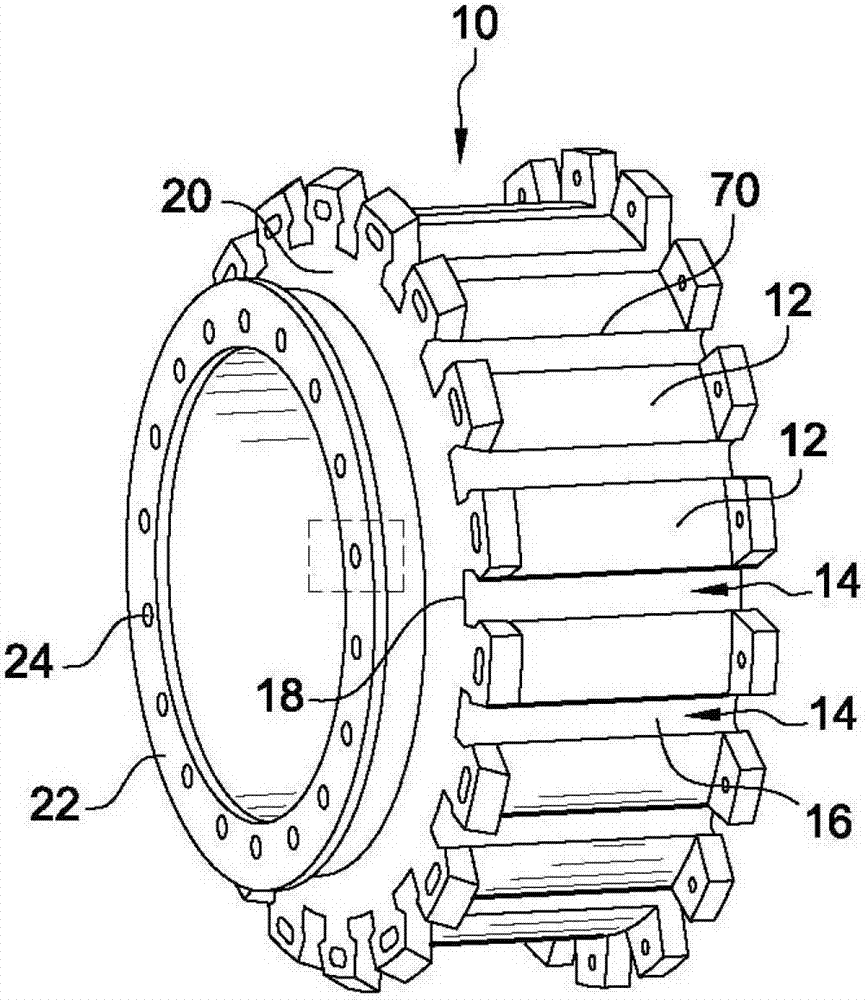

[0033] Initially referring to a rotor disk 10 in a turbomachine is shown figure 1 , the rotor disk 10 has on its periphery a plurality of key bars 12 interspersed with slots 14 for receiving wedge-shaped blade roots.

[0034] Thus, the bottom surface 16 of each groove 14 forms a right-angled edge 18 with the upstream face 20 and the downstream face of the disc 10 . Burrs are formed on these right angled sides when grooves 14 are formed in disc 10 and these sides 18 or corners need to be machined to remove the burrs and avoid any injury to the operator while handling disc 10 .

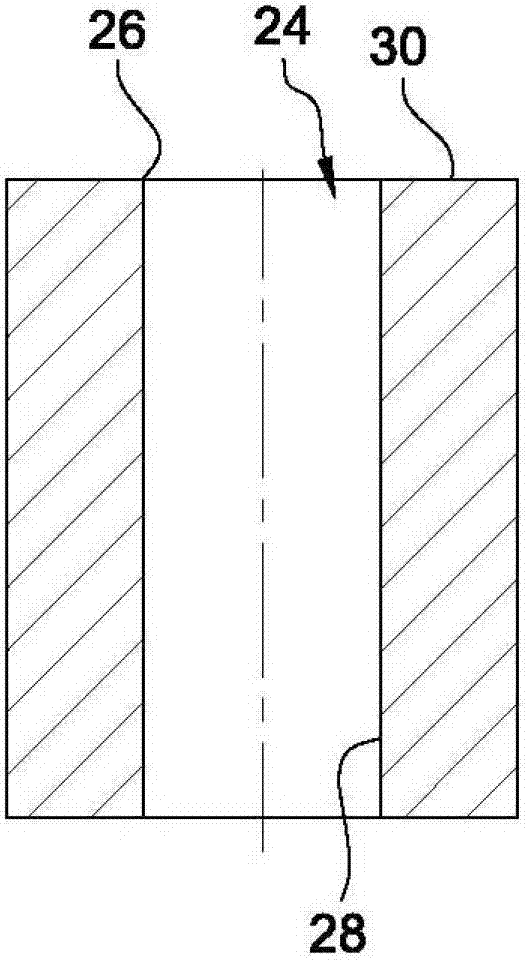

[0035] The rotor disk also has a flange 22 provided with a plurality of holes 24 evenly distributed around the axis of the rotor disk to facilitate fastening of the rotor disk 10 to an auxiliary structure. Each end of the hole 24 has an edge 26 (see figure 2 ).

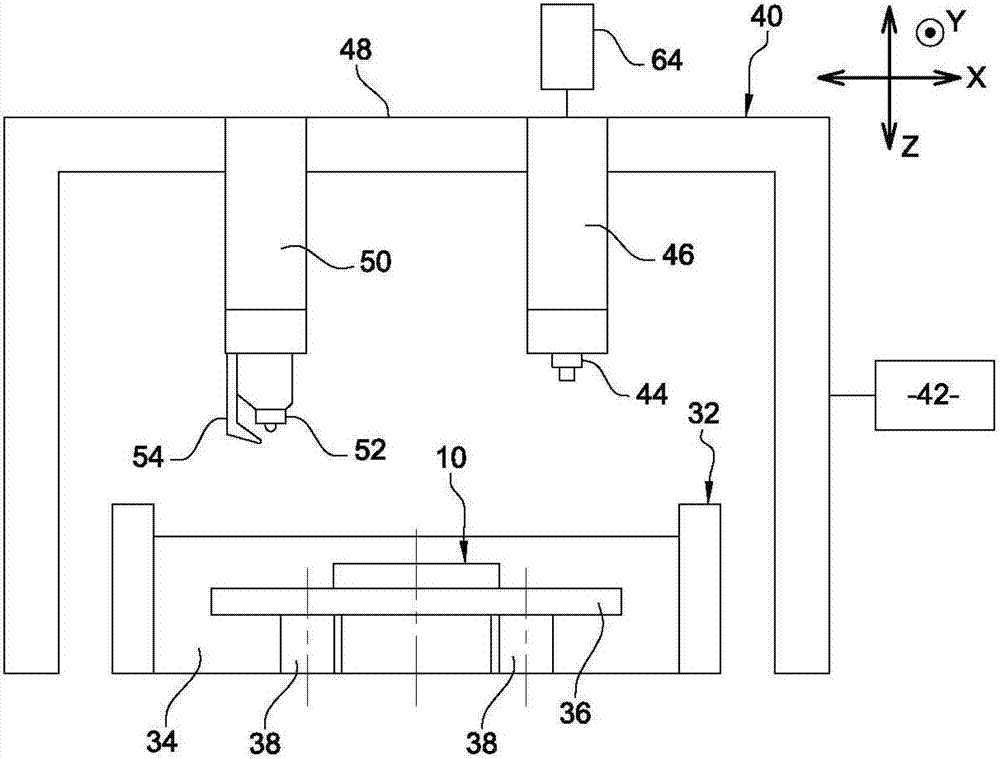

[0036] In the traditional way, the edges formed by these edges are manually broken off by the operator, which means that a uniform and nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com