System for integrating rivet nuts into plastic components

A technology for plastic parts and rivet nuts, applied in the direction of nuts, household components, threaded fasteners, etc., can solve the problems of material damage, crack formation, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

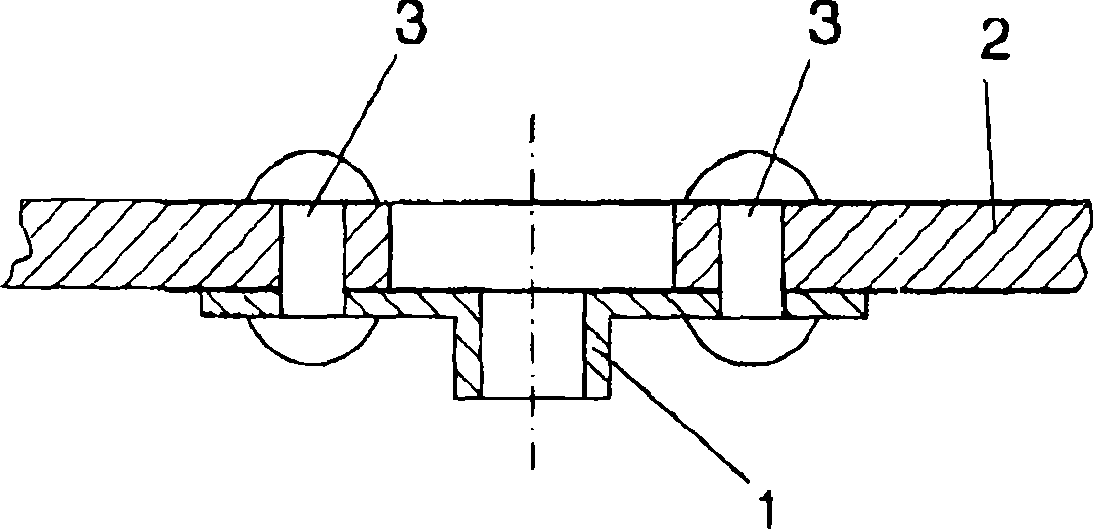

[0026] exist figure 1 As can be seen in , the traditional system of fastening rivet nuts 1 on synthetic plastic parts is achieved by means of conventional metal pins 3 which require corrosion protection at the ends of these pins 3 and which have Problems that may cause cracks in the plastic part 2.

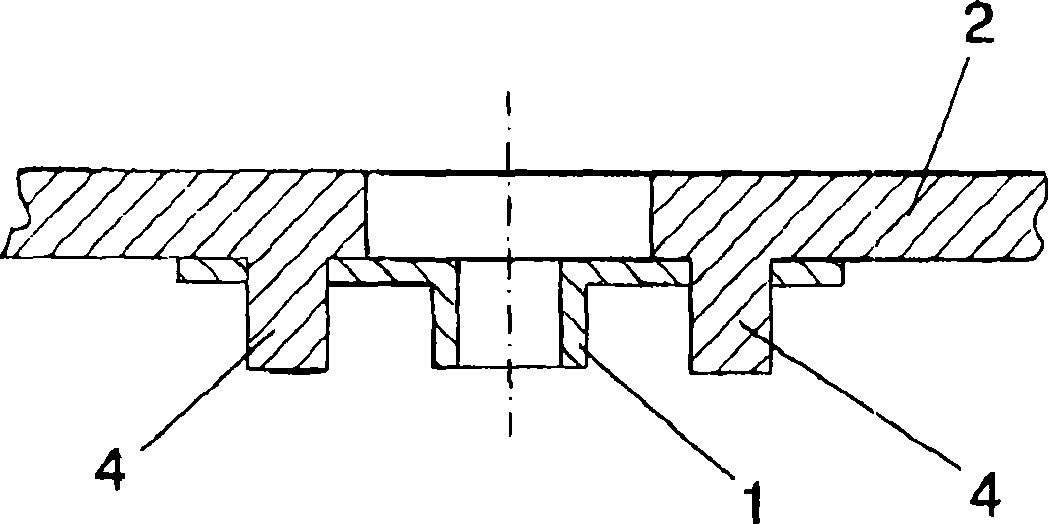

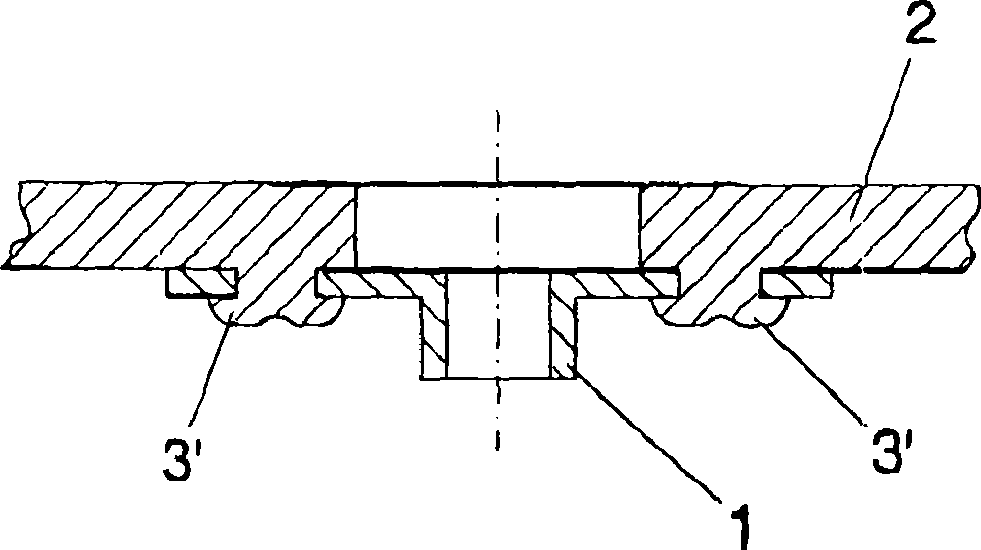

[0027] Therefore, in order to avoid these problems and inconveniences, the system of the present invention preferably adopts such as figure 2 and 3 Riveting is performed ultrasonically as shown or by any other method as appropriate. For this purpose, the part of plastic material to which the rivet nut 1 is riveted has a plurality of protrusions 4 which are formed as part of the manufacturing process of the plastic part 2, preferably by injection moulding. These projections 4 pass through corresponding holes made for the rivet nut 1 . Riveting 3' is then performed by ultrasonic or other methods such as image 3 shown.

[0028] Such as Figure 4 and 5 As shown, the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com