Apparatus and method for the production of bimaterial hollow bodies by means of injection overmoulding

A technology for overmolding and molding materials, which is used in the field of injection overmolding to produce bi-material hollow bodies. materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

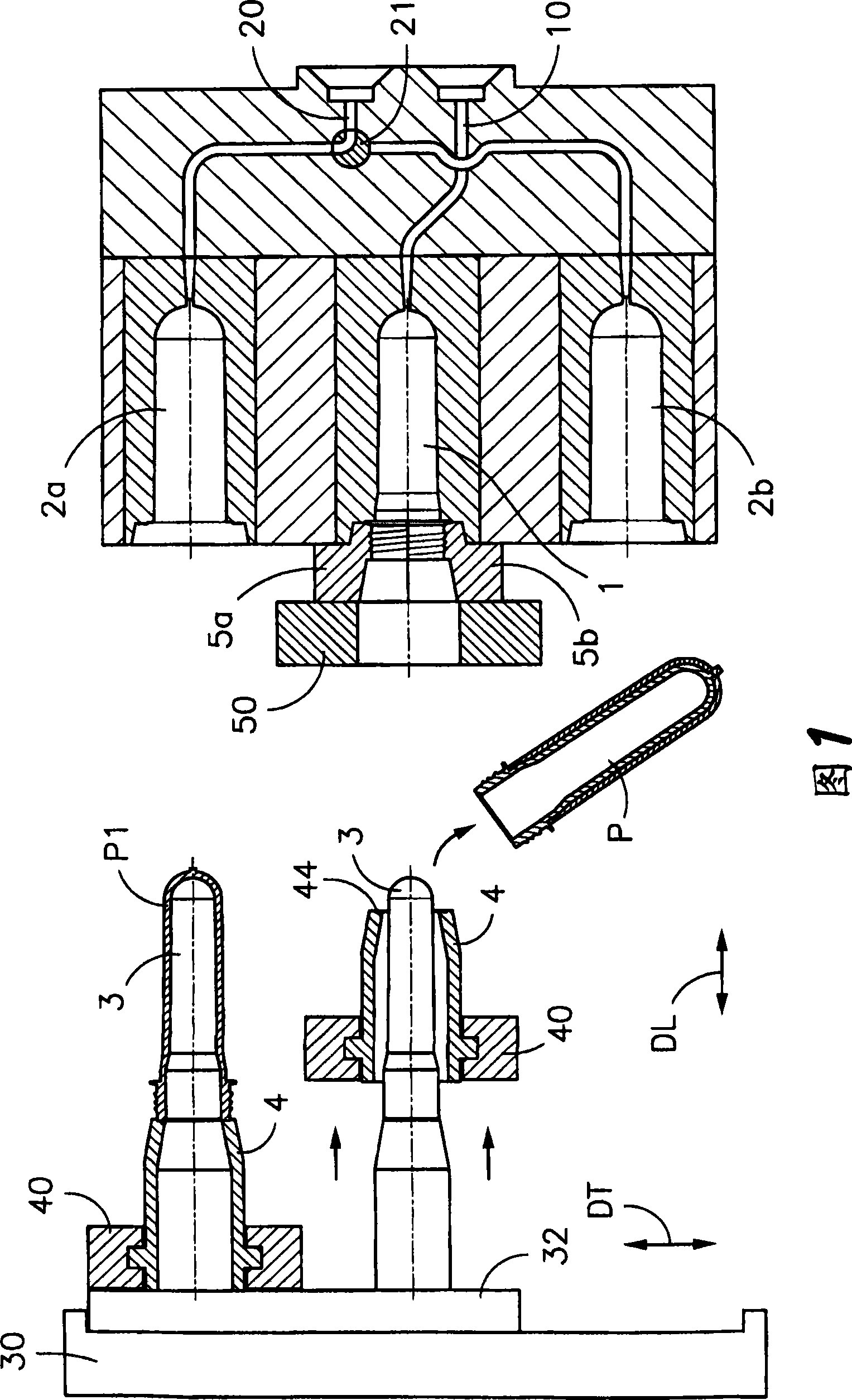

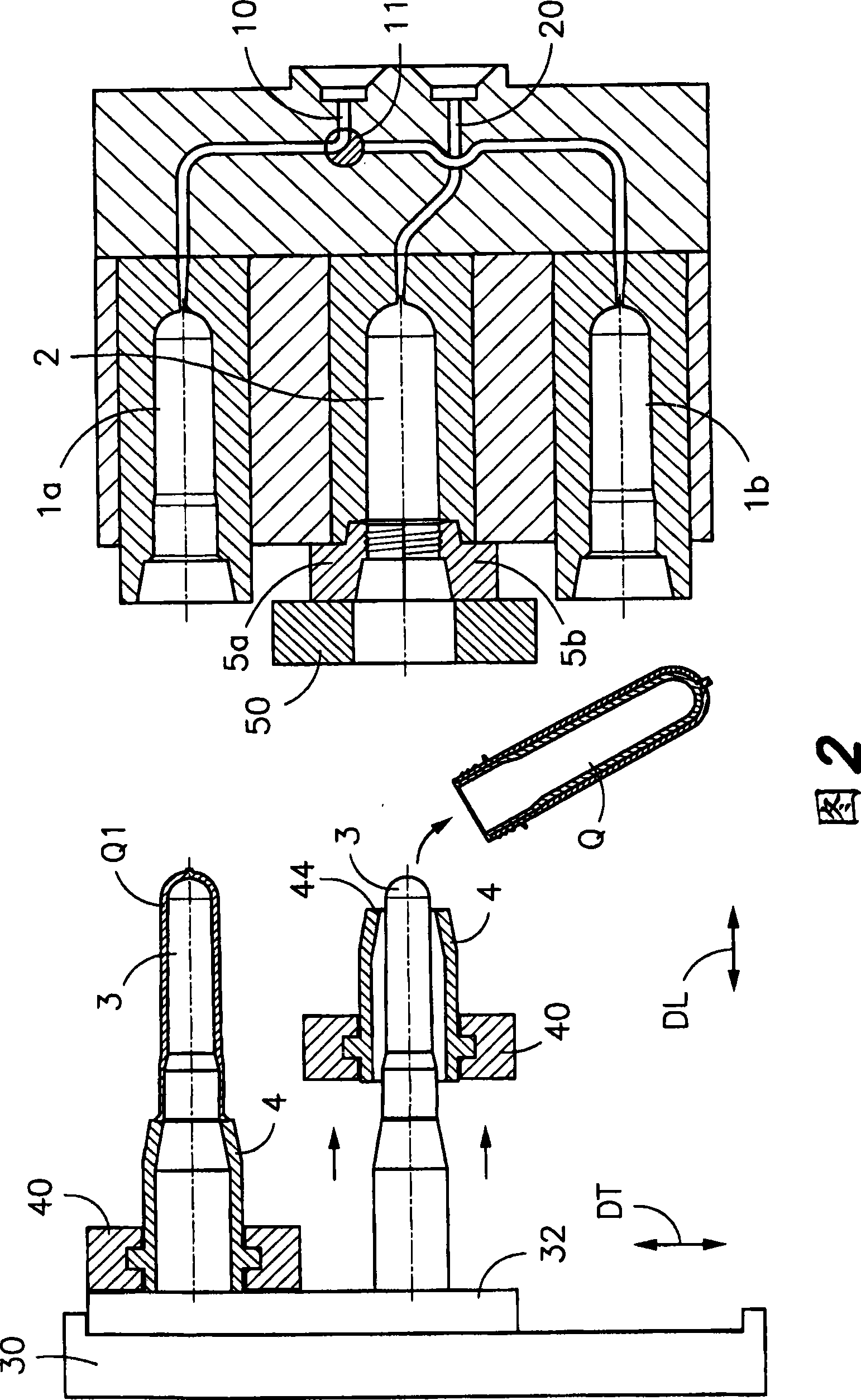

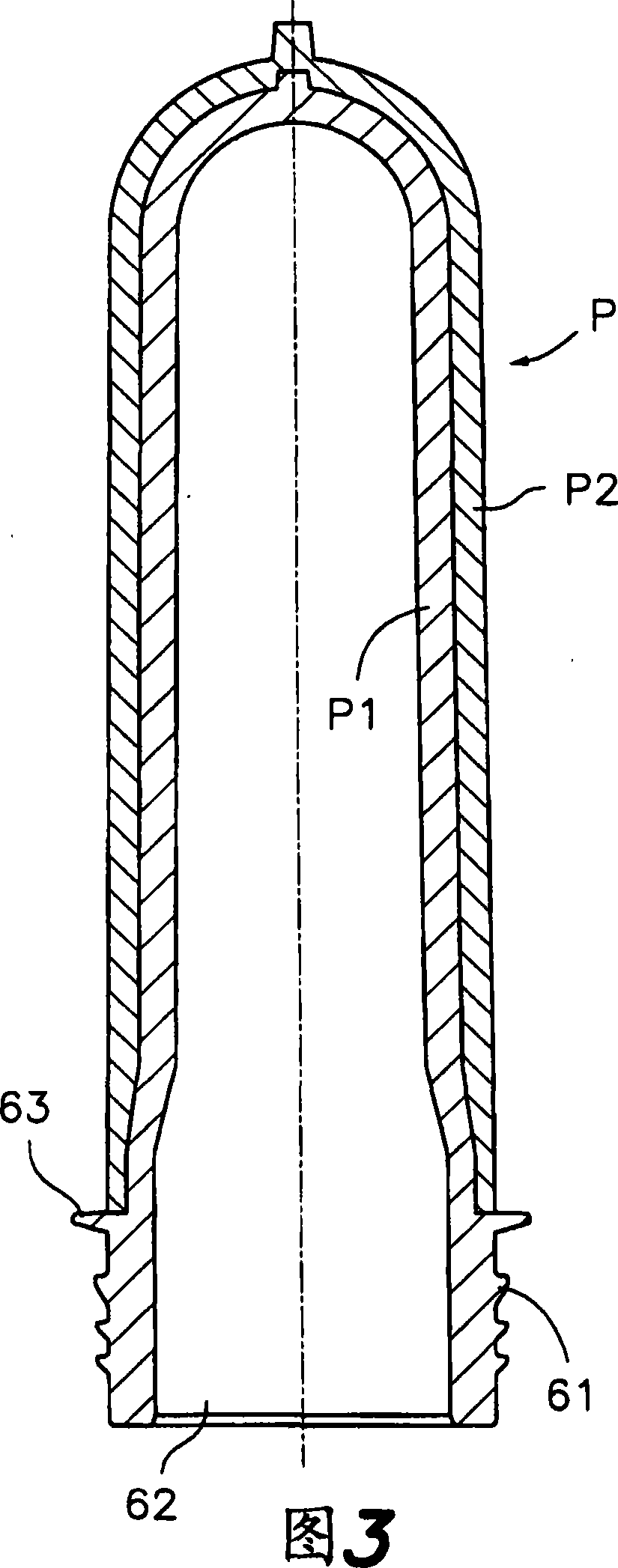

[0044] First, referring to FIG. 1, there is shown an apparatus for producing a bi-material hollow body by injection overmolding according to a simpler embodiment of the present invention. In the embodiment of FIG. 1, the hollow body is the first type of bi-material preform P shown in the longitudinal sectional view in FIG. 3.

[0045] The bi-material preform of FIG. 3 includes a hollow body of plastic material in the form of a test tube, the hollow body having a neck 61 and a mouth 62 with external threads and a peripheral annular flange 63. These preforms P are used for the subsequent production of plastic bottles by blowing. During the blowing process, the parts in the form of test tubes are inflated until the hollow body form of the bottle or container is obtained, while the neck 61, the mouth 62 and the peripheral annular flange 63 are unchanged. The bi-material preform P is formed by a first layer P1 and a second layer P2, the first layer P1 is a base molding material such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com