Transformer substation operation and maintenance pull rod tool cart of three-idler-wheel structure

A roller structure and substation technology, applied in the field of substation operation and maintenance, can solve the problems of inability to transport tools to the site at one time, affecting the timely rate of accident handling, and long time for preparing tools, etc. The effect of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

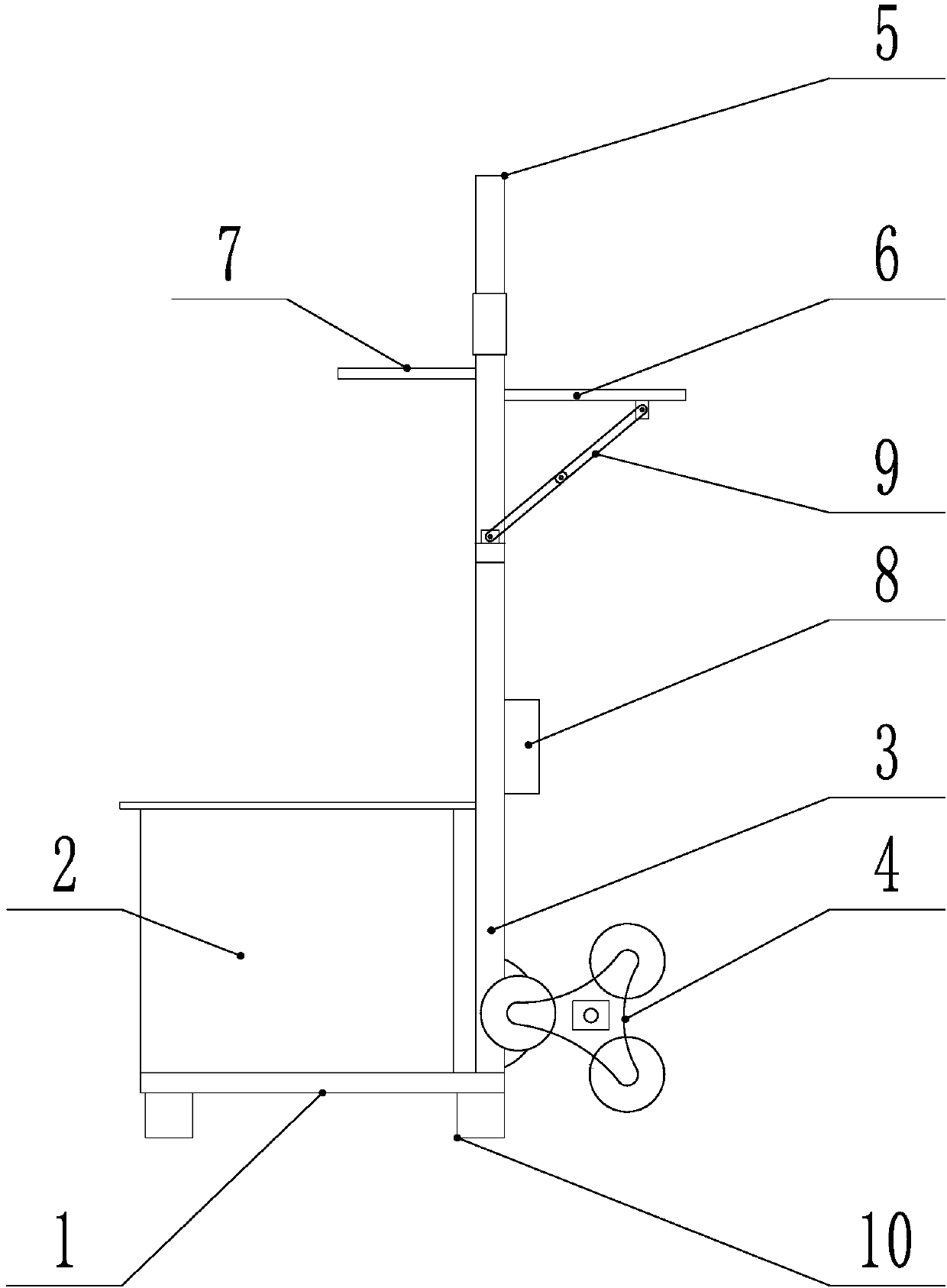

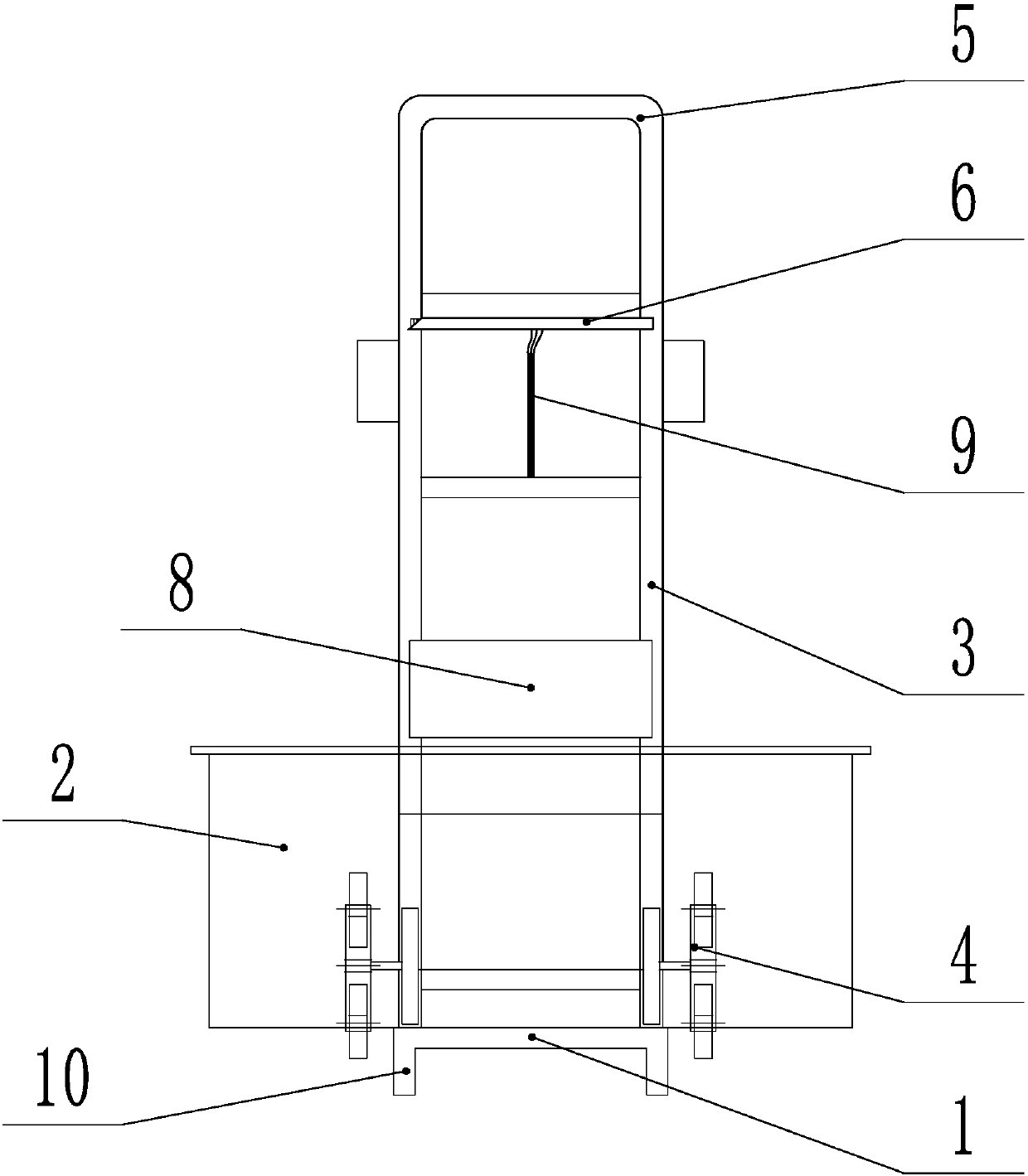

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-2 As shown in the figure, a substation operation and maintenance rod tool trolley with a three-roller structure includes a base plate 1, a vertical support 3 arranged on the right side of the top surface of the base plate 1, and a storage box 2 arranged on the base plate 1 for placing tools and components , two sets of casters 4 located on both sides of the lower right part of the support 3, handles 5 located at the top of the support 3, an operation ticket holder 8 for placing operation tickets is provided on the right side of the middle part of the support 3, and an operation ticket holder 8 is provided on the right side of the upper part of the support 3. The operation ticket platform 6 that can be turned down, the upper left side of the support 3 is provided with an insulating rod electroscope placement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com