Magnetic standing-up apparatus for can bodies

A kind of equipment, magnetic technology, applied in the field of equipment for manufacturing tanks, can solve the problems of equipment difficulty, equipment readjustment difficulty, increased risk of contact, etc., and achieve the effect of eliminating the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Note and definition:

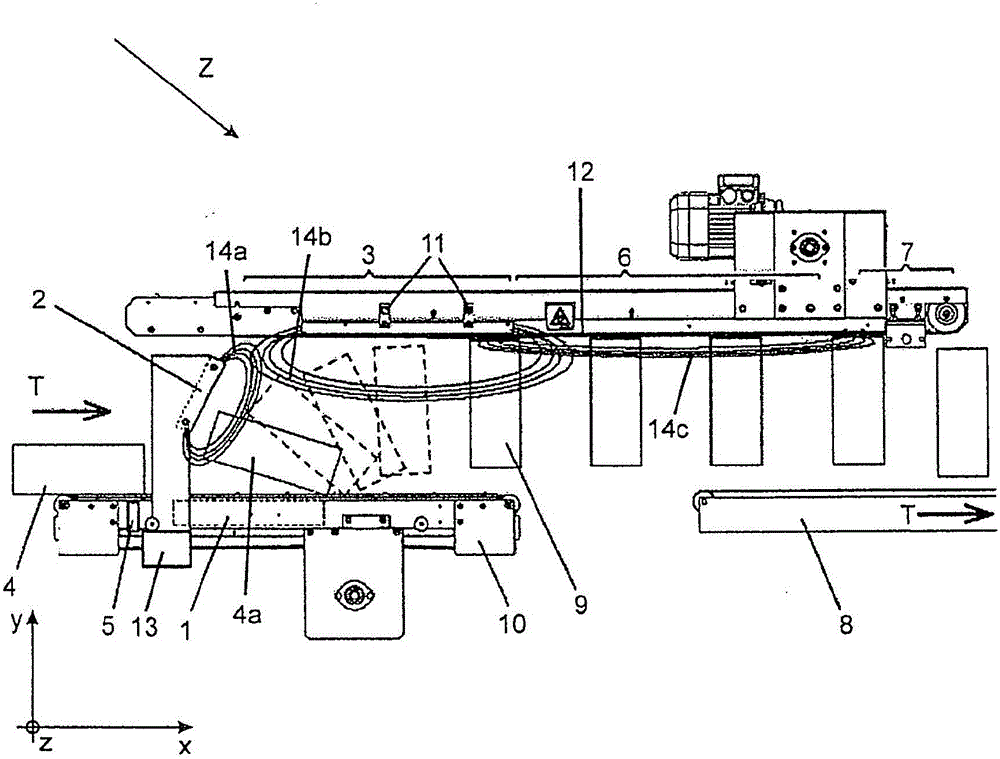

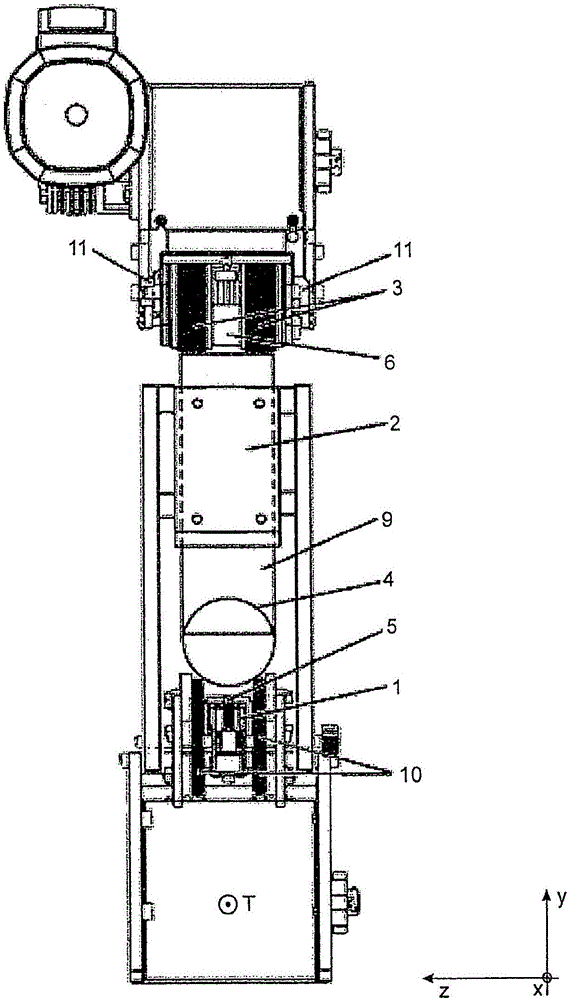

[0018] The different reference signs of the tank shall indicate the different state of the tank in terms of its orientation relative to the entry into the transport device 10 ( figure 1 ). Therefore, flat tanks are designated with reference number 4, tanks that are erected and transported in magnetic levitation are designated with reference number 9 and the tanks in the transition phase between the flat state and the erected state are designated with reference number 4a.

[0019] The concept "releasable" in relation to the magnet means here that the magnetic field strength of the magnet is only so strong that the canister within the range of the magnet can be lifted or lifted by a predefined external force, or the canister does not exist . Correspondingly, “fixable” means that the magnetic field strength of the magnet is so strong that the canister within the range of action of the magnet cannot be lifted or lifted by a predefined external force. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com