Inclined foliage beating machine

A blade and slope technology, applied in the field of oblique blade beaters, can solve the problems of reducing the speed at which the blade beats the pulp particles, the structure of the beater is complex, and the beating efficiency is low. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

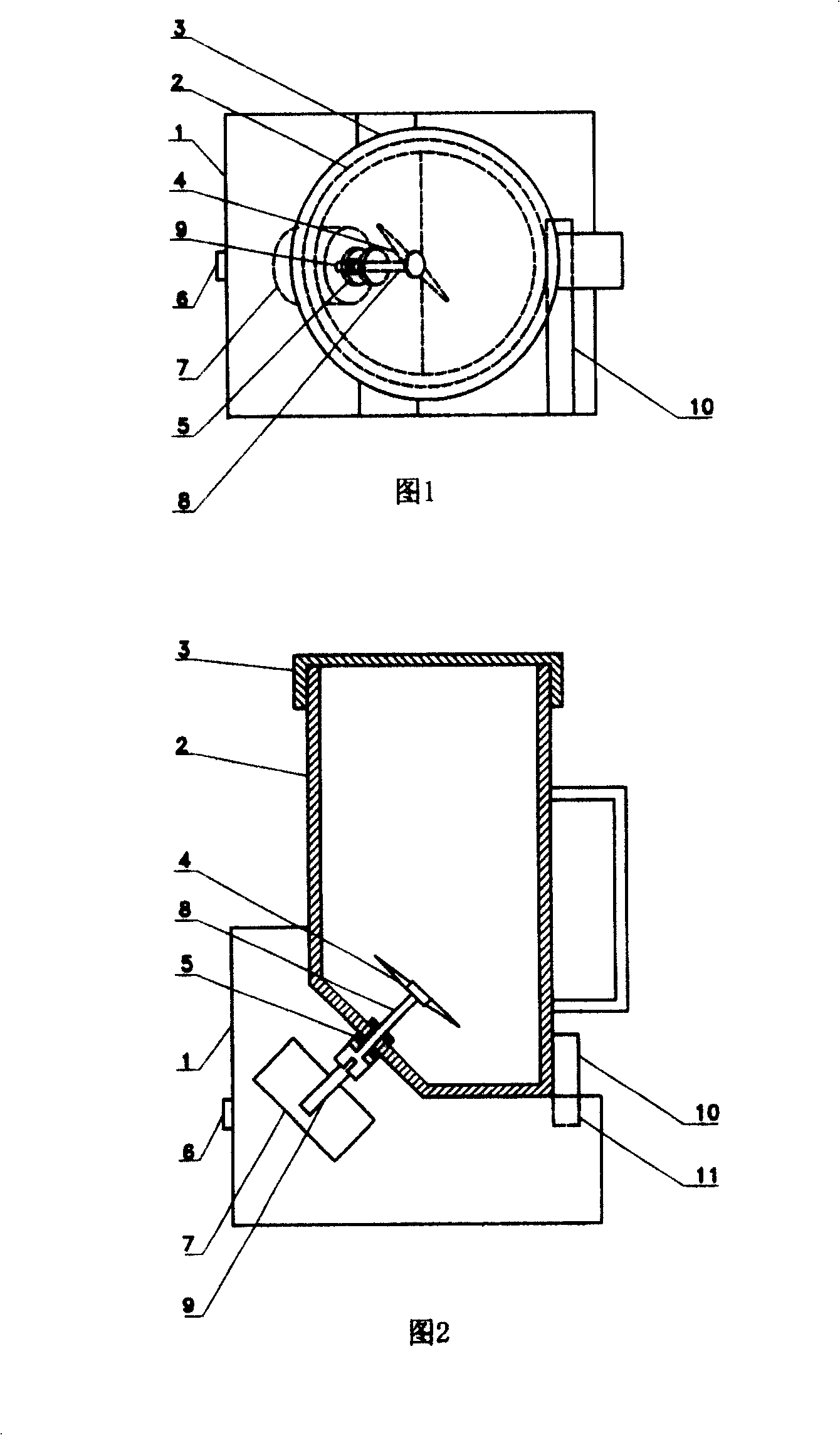

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The inclined blade beater consists of a base (1), a barrel (2), a barrel cover (3), an inclined blade (4), a sealing ring (5), a power switch (6), a motor (7), and a blade A rotating shaft (8), a motor rotating shaft (9), a block (10) and a chute (11) constitute. The side of the base (1) is "L" shaped, and its vertical part has a vertical arc-shaped groove, and the edge of the horizontal section of the groove is a 120-degree arc with a radius greater than 2mm of the outer diameter of the barrel (2). On the base (1) there is an inclined plane at an angle of 45 degrees with the horizontal plane, and the motor (7) is installed under the inclined plane, and the motor rotating shaft (9) stretches out from the rotating shaft hole at the bottom center of the concave hole in the middle of the inclined plane, and is perpendicular to the inclined plane. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com