Crystal boat box with inlet valve

A crystal boat box and air inlet valve technology, which can be used in electrical components, packaging under vacuum/special atmosphere, packaging objects under special gas conditions, etc., which can solve the problems of chip damage and inconvenience in opening the boat box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

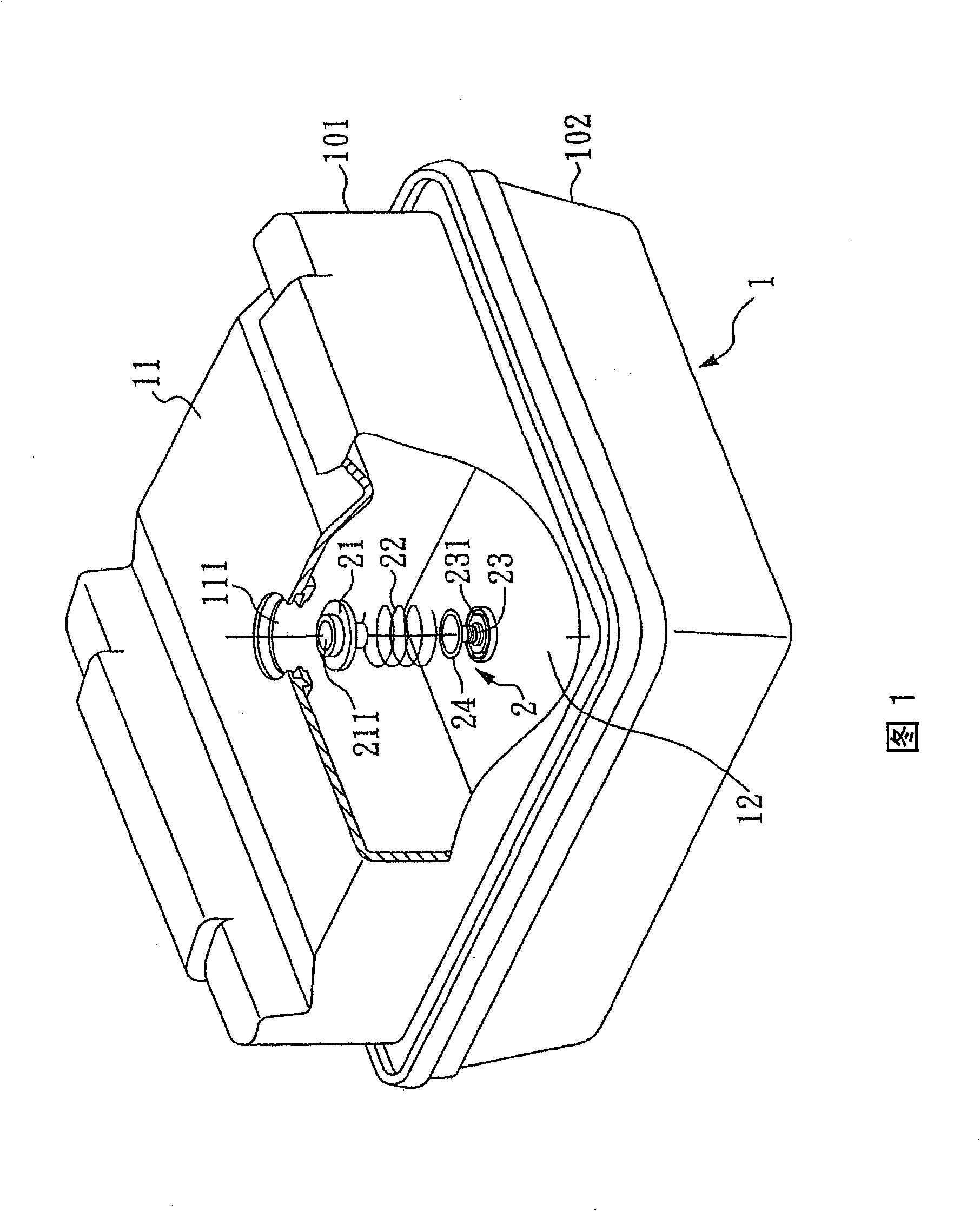

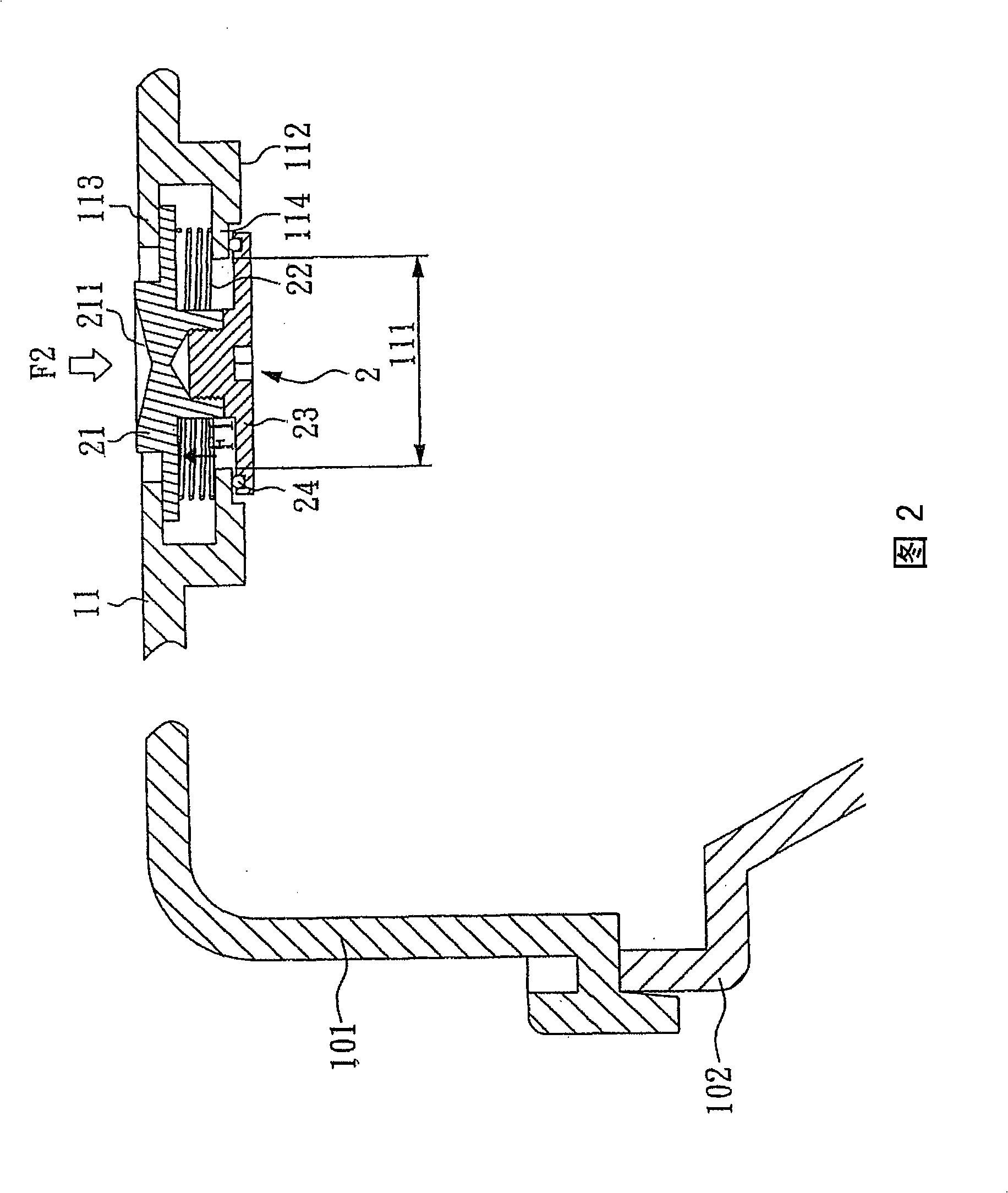

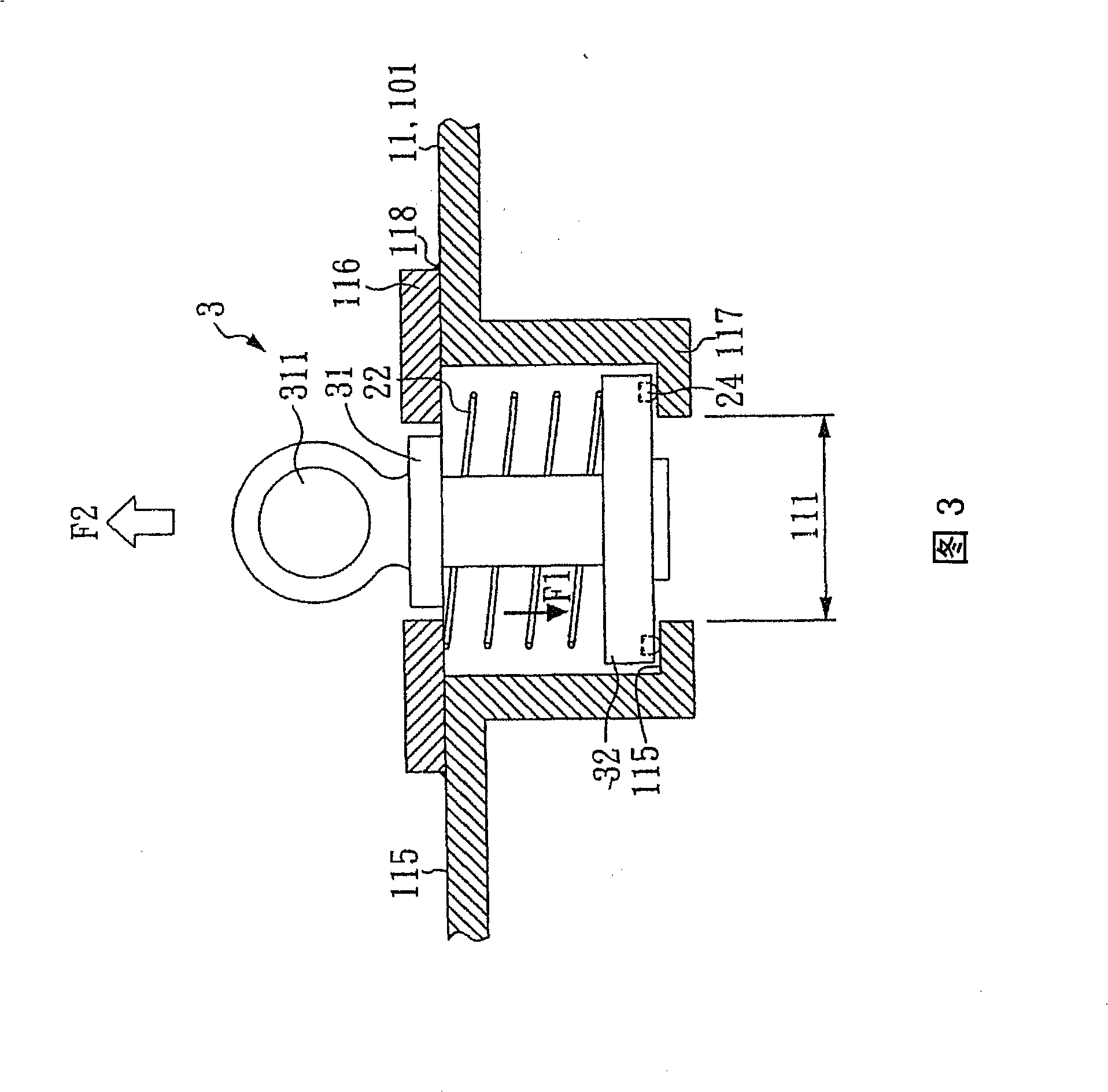

[0027] Please refer to FIG. 1, which is an exploded view of the first preferred embodiment of the present invention. As shown in the figure, the present invention is a wafer boat box with an air inlet valve, which mainly includes a box body 1 and an air inlet valve 2.

[0028] As shown in FIG. 1, the box body 1 of this embodiment includes a housing 11 and an internal space 12 therein. Wherein, the box body 1 of this embodiment is divided into a box cover 101 and a box body 102. The box cover 101 can be opened or is correspondingly closed on the box body 102 to form a closed internal space 12 around it. For ease of illustration and description, the case 11 in this example is an example of a top-opening wafer boat box for six-inch or eight-inch chips, and the case 11 located above the box cover 101 is taken as an example for illustration, but not This is a limitation. For example, the side surface or even the bottom surface of the entire box body 1 shown in FIG. 1 can be used; or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com