Automobile air spring

A technology for automobile gas springs and outer tubes, applied in the field of gas springs, can solve the problems of easy rotation of lower, upper and outer tubes, achieve good concentricity and eliminate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

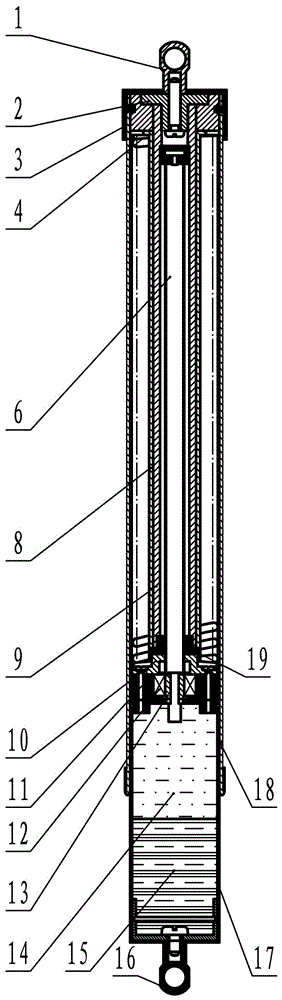

[0011] Such as figure 1 The automobile gas spring shown includes an upper outer tube 18 with an upper ball head 1 at one end, a lower outer tube 17 with a lower ball head 16 at one end, and a motor 15 is fixed in the lower outer tube 17; the motor 15 passes through a gearbox 14 Connected with screw mandrel 6, screw mandrel 6 is provided with protruding part at one end, and the protruding part of screw mandrel 6 passes through the center hole of fixing sleeve 11 and is connected with gearbox 14, and the end of the protruding part of screw mandrel 10 passes flower The key is connected with the gearbox; a bearing 12 is provided between the extension of the screw rod 6 and the fixed sleeve 11, and the bearing 12 is set on the extension of the screw rod 6 through the shaft sleeve 13; between the screw rod 6 and the gearbox 14 A fixed sleeve 11 is arranged between them, and the fixed sleeve 11 is fixedly connected on the lower outer tube 17; an upper outer tube 18 that can move alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com