Optical fiber bundle fusion packaging device and packaging method

The technology of a packaging device and packaging method, which is applied in the direction of bundled optical fibers, can solve the problems of affecting the effect of induction heating, complicated optical fiber metallization process, and high cost of optical fiber metallization, so as to achieve fast molding, eliminate the risk of optical fiber damage, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

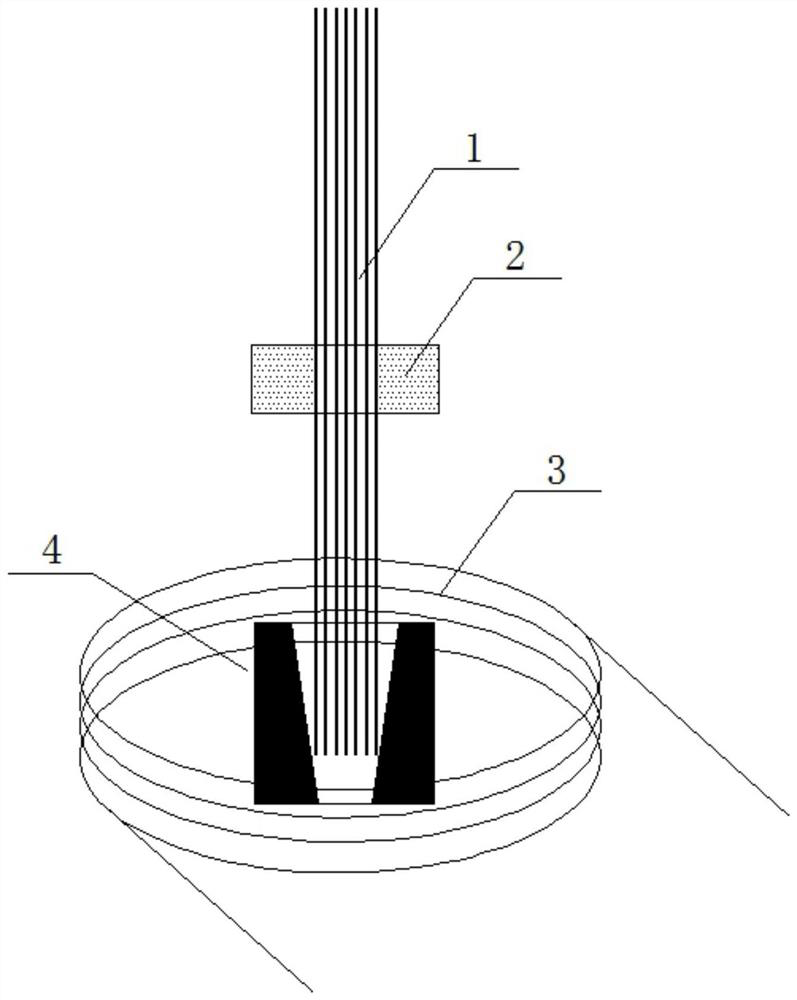

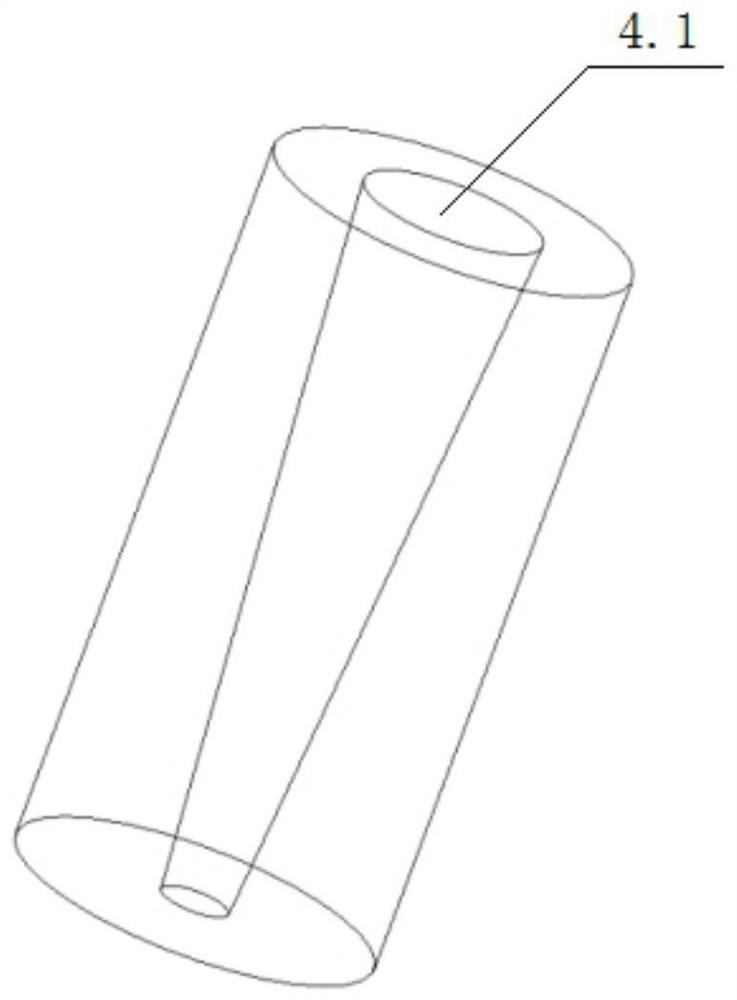

[0024] like figure 1 , 2 As shown, an optical fiber bundle fusion packaging device in this embodiment includes a cylindrical lateral pressing mold 4, and the lateral pressing mold 4 is set in the inner cavity of the high-frequency induction heating equipment, so that the high-frequency induction heating equipment The induction coil 3 surrounds the lateral press mold 4. A through fiber passage 4.1 is set in the center of the lateral press mold 4, and the diameter of the entrance end of the fiber passage 4.1 is larger than the diameter of the outlet end of the fiber passage 4.1, so that the longitudinal section of the fiber passage 4.1 is an inverted trapezoid. The bare fiber section of the fiber bundle 1 is arranged in the fiber passage 4.1, and the diameter of the exit end of the fiber passage 4.1 corresponds to the diameter of the fiber bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com