Method for quantitatively evaluating light distribution performance of automotive headlamp

A technology for automotive headlights and light distribution performance, which is applied in the field of motor vehicle lighting, and can solve problems such as inability to visually evaluate, and judgment of whether the light distribution performance of headlights is qualified or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

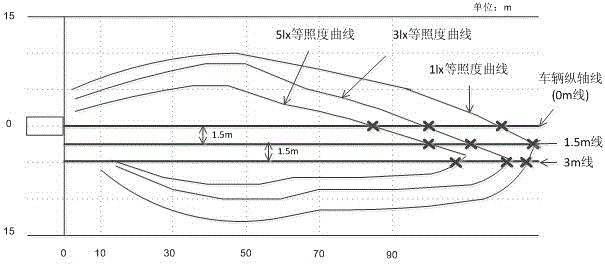

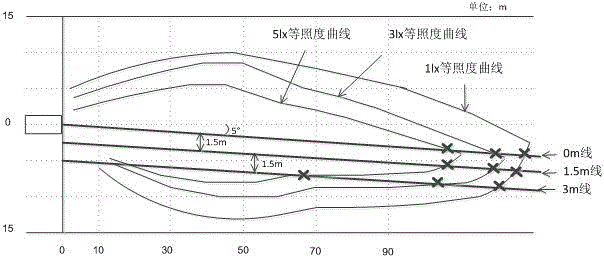

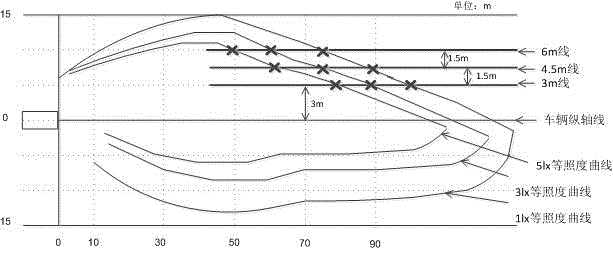

[0051] Such as figure 1 As shown, a method for quantitative evaluation of light distribution performance of automobile headlights, including the following steps:

[0052] S1: Establish a vehicle headlight light distribution database and divide the headlight light distribution performance into several levels. In this embodiment, a total of five levels are set. The vehicle headlight light distribution database stores several headlight As a sample, the headlamps in the database are numbered, and each headlamp sample is tested separately to obtain the light distribution performance parameters of each sample, and the light distribution performance parameters and the headlights are correspondingly filled in the Vehicle headlight light distribution database;

[0053] In the present invention, in order to accurately evaluate the performance parameters of the headlamp in various occasions, the performance parameters are divided into low beam parameters and high beam parameters;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com