Reversible protective cover

A protective cover and flip-type technology, applied in the field of CNC machine tools, can solve the problems of low replacement efficiency and waste falling outside the protective structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

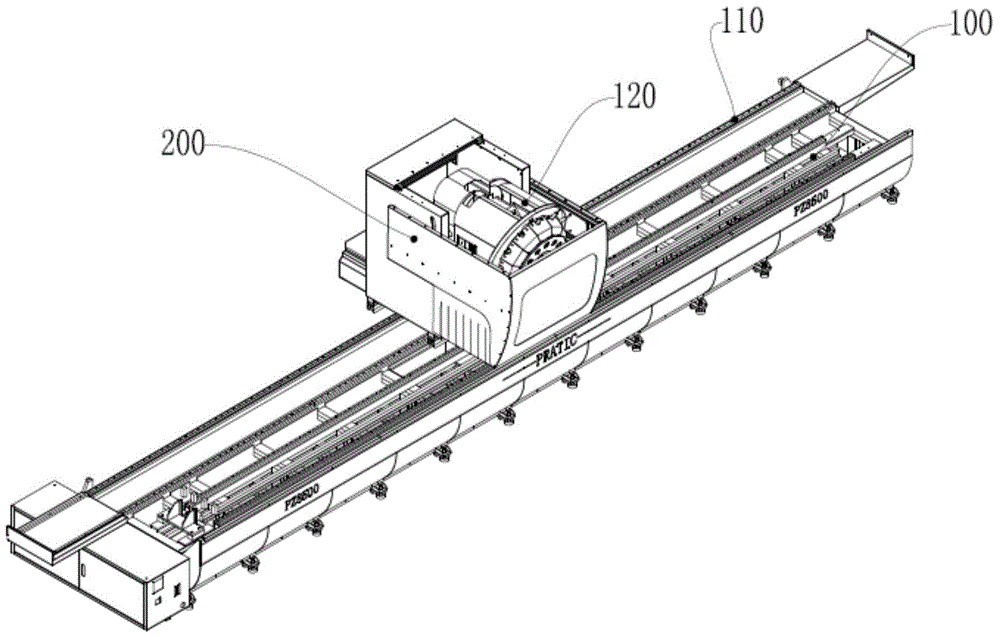

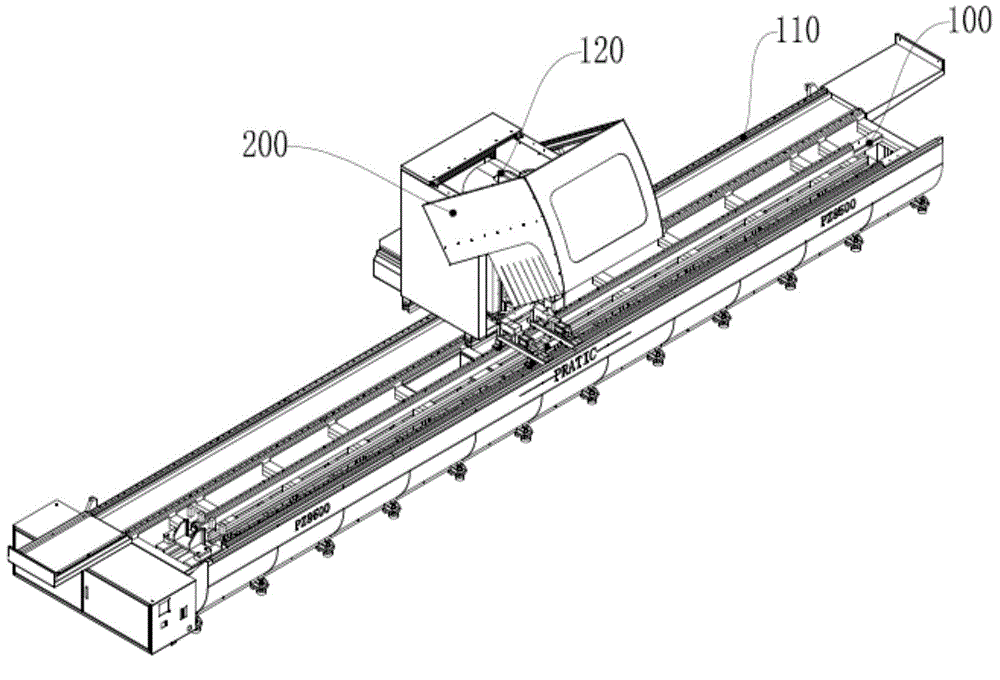

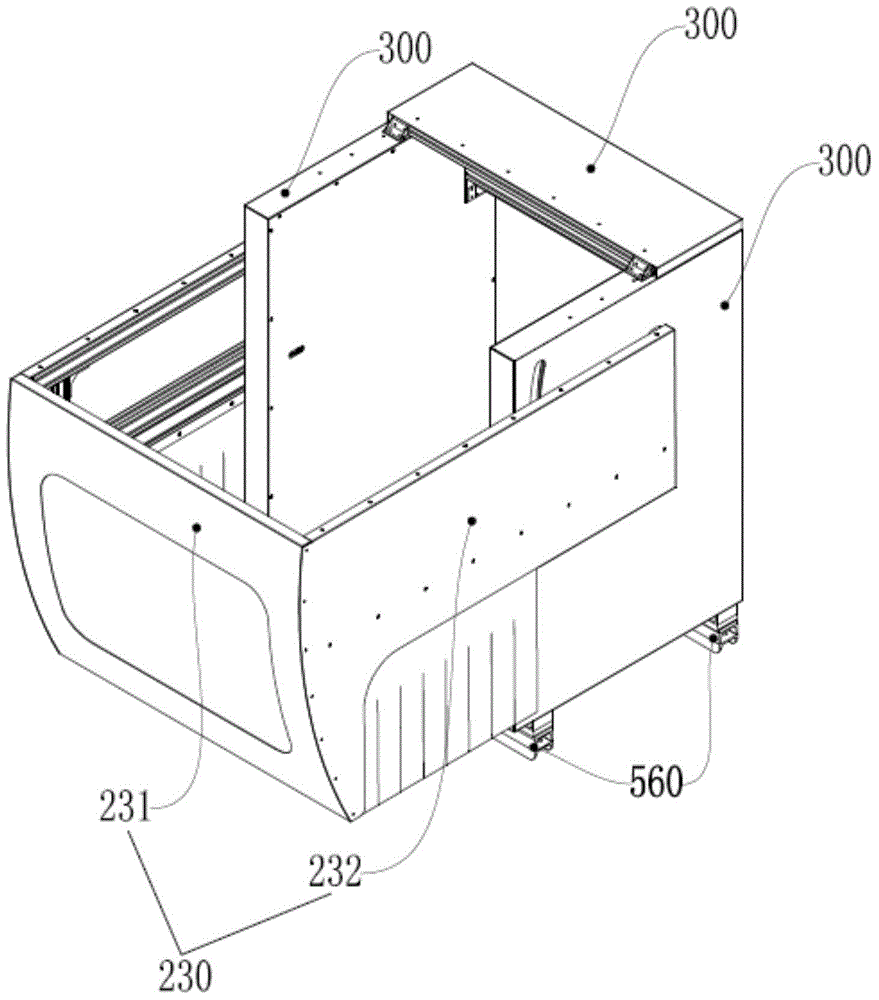

[0026] Such as Figure 1-6 As shown, a rotating protective safety cover includes a fixed frame, a rotating frame and a protective plate 230, and the fixed frame includes a side frame 211 and a bottom frame 212, and the side frames 211 are respectively arranged on the top of the bottom frame 212. Left and right sides; the protective plate 230 includes an arc-shaped baffle 231 and a housing 300; the rotating frame includes two turrets 221 symmetrically arranged on the left and right sides; one end of the rotating frame is fixed to the arc-shaped baffle 231 , the turret 221 on both sides of the other end is hinged to the side frame 211 through bolts 520 and bearings 500 respectively; the fixed frame is provided with a driving device that can drive the turret 221 to rotate; the turret 221 is provided w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap